The Advantages and Applications of Long Span Roll Forming Machines

In the modern manufacturing landscape, efficiency and precision are paramount. One exceptional technology that has gained significant traction is the long span roll forming machine. This innovative production equipment is designed to create long, continuous profiles with high dimensional accuracy, making it an indispensable tool in various industries.

What is a Long Span Roll Forming Machine?

A long span roll forming machine is a specialized equipment that processes metal sheets into continuous profiles. The machine operates by passing metal strips through a series of rollers, which gradually shape the material into the desired cross-section. The “long span” characteristic refers to the machine’s capacity to produce elongated profiles, often exceeding several meters in length, without the need for joints or seams. This continuous forming reduces material waste and lowers production costs.

Key Advantages

1. High Efficiency Long span roll forming machines enable manufacturers to produce large quantities of profiles in a short time. The automated nature of the process allows for quick changeovers, significantly enhancing operation efficiency.

2. Precision and Quality These machines offer exceptional precision in profile formation. The rollers are designed to ensure uniformity and accuracy, resulting in high-quality end products that meet stringent specifications.

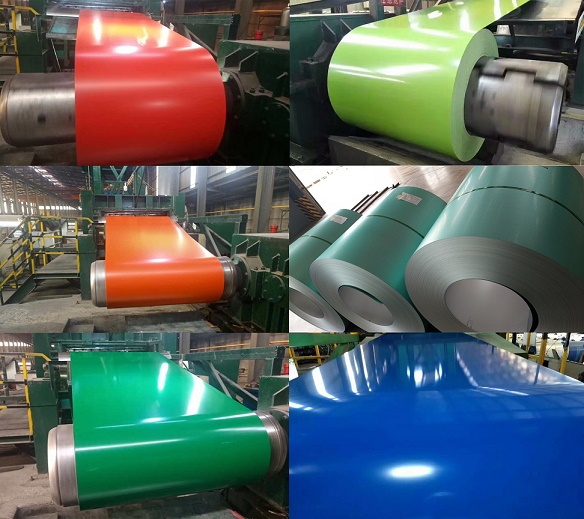

3. Material Versatility Long span roll forming machines can process a variety of materials, including steel, aluminum, and other metals, making them suitable for diverse applications. Moreover, they can accommodate different thicknesses and widths of material, adding to their flexibility.

4. Cost-Effectiveness By minimizing waste and reducing labor costs through automation, long span roll forming machines provide a cost-effective solution for manufacturers. The high production rate also translates into better profitability.

5. Reduced Installation Time The creation of long, continuous sections means fewer joints or seams, which simplifies installation processes in construction and fabrication applications.

Applications Across Industries

Long span roll forming machines are widely used across multiple sectors, including

- Construction One of the primary applications is in the construction industry, where long span profiles are used for roofing, wall cladding, and structural framing. These profiles provide strength and durability, making them ideal for modern building designs.

- Automotive In automotive manufacturing, roll-formed products are used for producing frames, reinforcements, and other structural components that require strength and lightweight characteristics.

- Furniture The furniture industry also benefits from long span roll forming for producing components with unique shapes and designs, allowing manufacturers to innovate continuously.

- Electrical Engineering Long span roll forming machines are employed to create enclosures, racks, and supports for electrical systems, where precision and reliability are critical.

Conclusion

As industries continue to evolve and demand higher standards of efficiency and quality, long span roll forming machines stand out as a vital technology in manufacturing. Their ability to produce high-quality, long profiles efficiently makes them an essential asset across various sectors. By investing in these machines, manufacturers can enhance productivity, reduce costs, and maintain a competitive edge in an increasingly demanding market. The future of roll forming technology looks promising, with advancements anticipated in automation and digitalization, further propelling the capabilities of long span roll forming machines.