Understanding the AASHTO M180 Cold Bending Machine

The AASHTO M180 standard is a critical guideline established by the American Association of State Highway and Transportation Officials (AASHTO) that pertains to the specifications of cold bending machines used in the fabrication of steel reinforcement bars (rebar). These machines play a vital role in ensuring that the steel components used in construction are shaped and formed accurately to meet stringent structural requirements. This article will provide an overview of the AASHTO M180 cold bending machine, its significance in construction, and its essential features.

Understanding the AASHTO M180 Cold Bending Machine

One of the primary advantages of using a cold bending machine is that it allows for the bending of steel at lower temperatures compared to traditional hot bending methods. Cold bending retains the rebar's mechanical properties, leading to superior strength and ductility in the final product. Adhering to the AASHTO M180 standard ensures that these machines are capable of bending rebar without causing significant alterations in the steel's microstructure, which is crucial for maintaining strength and durability.

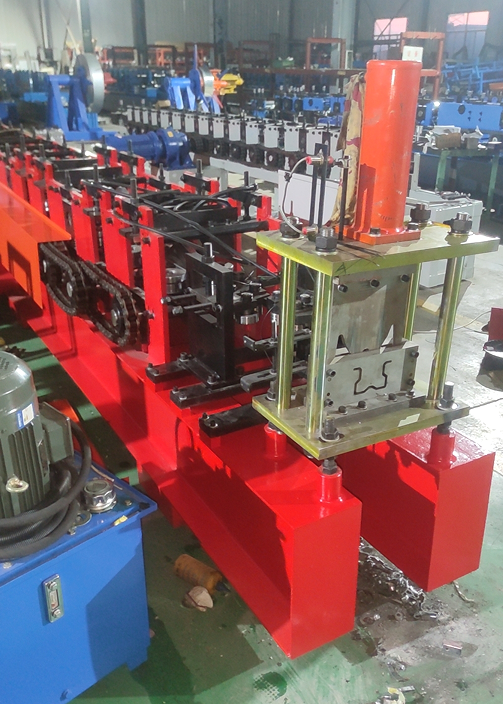

Features of the AASHTO M180 cold bending machines include precise control mechanisms, adaptability to various sizes of rebar, and robust construction that can withstand repetitive use. These machines typically come equipped with hydraulic systems that can exert substantial force necessary for bending thicker and larger diameter bars efficiently. The user interface of these machines is often designed to facilitate ease of operation, allowing operators to program specific bending angles and lengths, reducing the risk of human error.

Moreover, compliance with AASHTO M180 also demands comprehensive testing procedures to verify that the machines produce bends that meet specified angles and radii consistently. This testing often includes ensuring that the bends do not introduce cracks or weaknesses in the material, which could compromise structural integrity when the bars are placed under load. The incorporation of digital monitoring systems in many modern machines aids in continuous quality control and instant feedback.

In addition to structural integrity, the use of AASHTO M180 cold bending machines contributes to overall project efficiency. By streamlining the bending process, these machines can significantly reduce the amount of manual labor required and the time it takes to prepare rebar for construction. This enhanced efficiency translates into cost savings and faster project completion times, making them invaluable tools in modern construction practices.

In conclusion, the AASHTO M180 cold bending machine is a fundamental asset in the construction industry, specifically for projects requiring the use of steel reinforcement bars. Adhering to the AASHTO M180 standards ensures not only the efficiency and quality of the bending process but also the safety and durability of the structures being built. As technology and techniques evolve, these machines will continue to play a crucial role in shaping the future of construction, marrying tradition with innovation for better building practices. Understanding and implementing the AASHTO M180 standards will be vital for engineers, architects, and construction professionals dedicated to achieving excellence in their work.