Understanding Cable Tray Roll Forming Machine Prices

In the contemporary world of manufacturing and construction, cable tray roll forming machines play a pivotal role in the production of essential infrastructure components. These machines are designed to create cable trays, which are used for supporting and securing electrical cables and wiring in commercial and industrial buildings. As the demand for reliable and efficient cable management solutions continues to rise, understanding the pricing of cable tray roll forming machines becomes increasingly important for businesses and manufacturers looking to invest in this technology.

The Basics of Cable Tray Roll Forming Machines

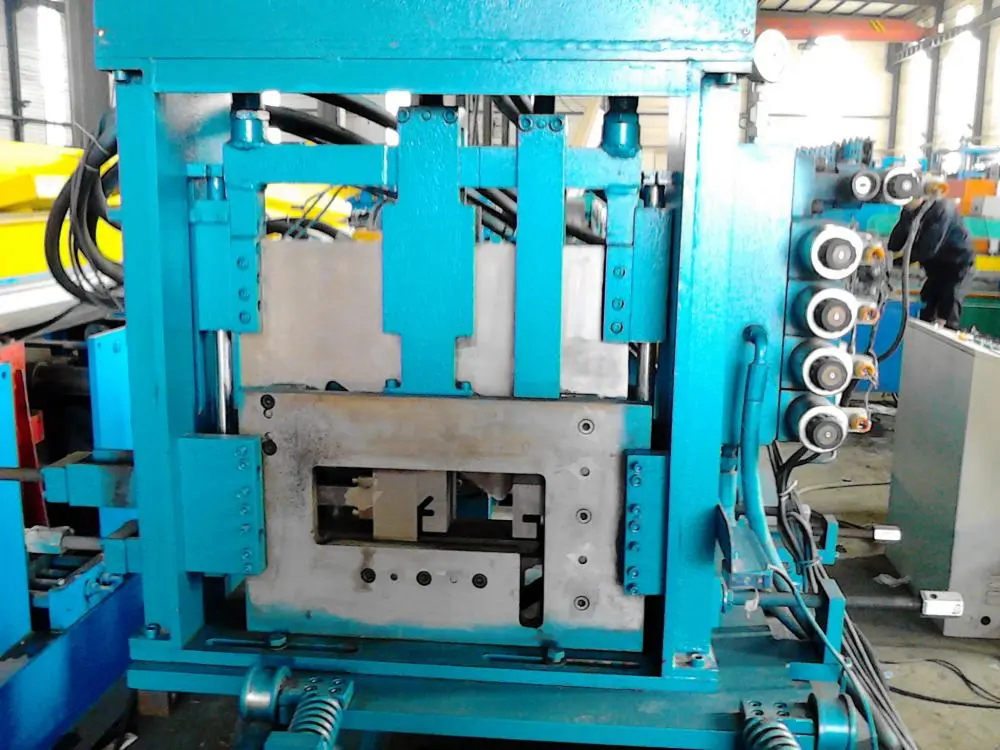

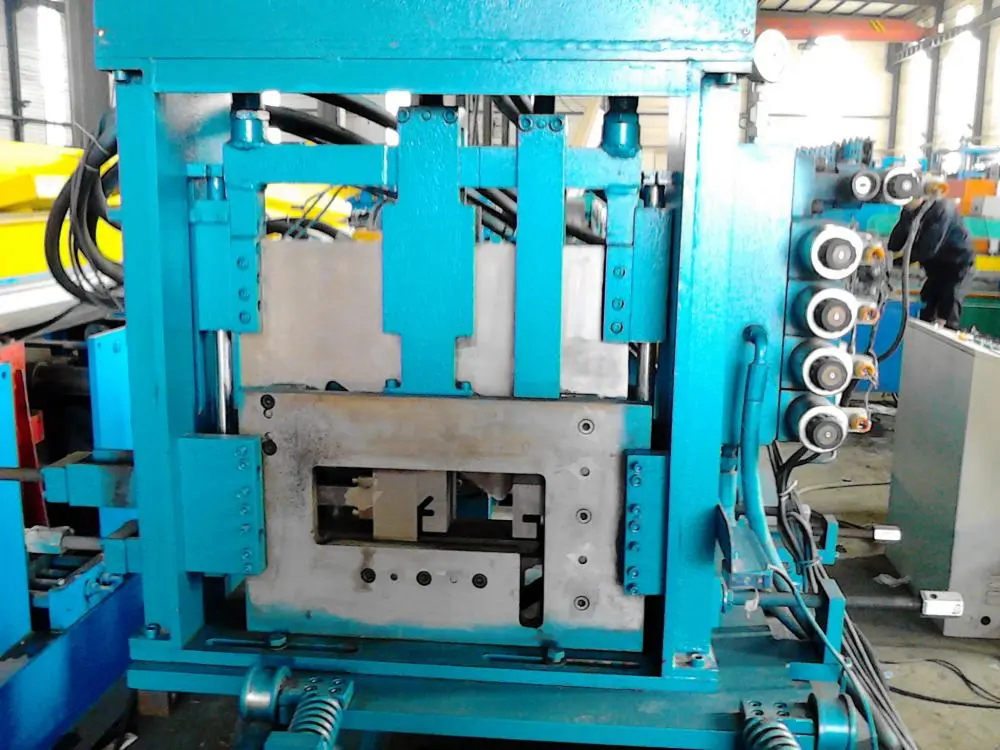

Cable tray roll forming machines mechanize the process of transforming flat steel sheets into structured cable trays through a series of shaping and bending operations. The process generally involves feeding the raw material into the machine, which then shapes it into the desired profile as it passes through a series of rollers. This automated approach not only enhances productivity but also ensures consistency and precision in the final products.

Factors Influencing Pricing

The price of cable tray roll forming machines can vary significantly based on several factors

1. Machine Specifications The size and complexity of the machine greatly influence its price. Basic models designed for smaller operations may be more affordable, while larger, high-capacity machines capable of producing more intricate designs will usually command higher prices.

2. Material Quality The quality of materials used in the construction of the machine also impacts the cost. Premium materials can enhance durability and longevity, but they also increase the overall investment.

cable tray roll forming machine price

3. Automation Level Machines that incorporate advanced automation features, such as computerized controls, automated feeding systems, and high-speed operations, often come with a higher price tag. However, these features can significantly improve production efficiency and reduce labor costs over time.

4. Brand Reputation Established manufacturers with a strong reputation for quality and service may charge more for their machines. While this can represent a higher initial outlay, investing in reputable brands often leads to better after-sales support and reliability.

5. Customization Options Many manufacturers offer customization options that allow clients to tailor machines to their specific needs. Custom features can increase costs but may provide a better fit for particular production requirements.

6. Market Conditions Economic factors and industry demand can also play a role in pricing. Fluctuations in the cost of raw materials, foreign exchange rates, and regional economic conditions can affect the final price of these machines.

The Investment Perspective

While the upfront cost of cable tray roll forming machines can be substantial, it is essential to view this investment through a long-term lens. A quality roll forming machine can streamline the production process, reduce material waste, and enhance product quality, all of which contribute to increased profitability over time. Additionally, businesses that invest in modern machines often benefit from lower maintenance costs and improved operational efficiency.

Conclusion

In conclusion, the price of cable tray roll forming machines is influenced by various factors, including machine specifications, material quality, automation levels, brand reputation, customization options, and market conditions. Understanding these aspects is crucial for businesses looking to make informed investment decisions. Ultimately, while the initial cost may seem daunting, the benefits derived from investing in high-quality machinery can lead to significant returns, making cable tray roll forming machines a valuable asset in today’s manufacturing landscape.