Understanding Changeable C Purlin Roll Forming Machines

In the construction and manufacturing industries, structural components play a crucial role in ensuring the stability and integrity of buildings and structures. One such component is the C purlin, a versatile steel component used to support roofs and walls. The introduction of changeable C purlin roll forming machines has revolutionized the production of these essential elements by enhancing efficiency, flexibility, and customization.

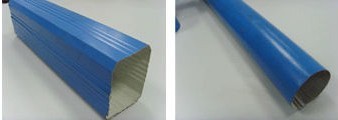

A changeable C purlin roll forming machine is specifically designed to produce C purlins of various sizes and specifications from steel coils. What sets these machines apart from traditional roll forming machines is their ability to easily switch between different profiles and dimensions. This capability is not only time-saving but also allows manufacturers to meet diverse customer needs without the need for investing in multiple machines.

The operation of a changeable C purlin roll forming machine typically starts with the feeding of a steel coil into the roll forming line. The machine rolls and shapes the coil through a series of forming stations, gradually creating the desired C shape. The adjustment mechanisms in these machines enable operators to modify the width, height, and thickness of the purlins quickly and efficiently, accommodating various project requirements and enhancing production versatility.

One of the key benefits of utilizing a changeable C purlin roll forming machine is the reduction in material wastage. Traditional production methods often lead to excess scraps when producing different sizes. However, with a changeable system, adjustments can be made on-the-fly, ensuring optimal use of materials and reducing costs. This efficiency not only appeals to manufacturers but also aligns with the growing emphasis on sustainability within the industry.

Furthermore, changeable C purlin roll forming machines are equipped with advanced technology, including automated controls and digital monitoring systems. These features not only enhance the precision of the rolls but also allow for real-time adjustments during the production process, ensuring consistency and quality in the finished products. The integration of smart technology also facilitates better maintenance and helps prevent downtime, further ensuring that production remains uninterrupted.

In conclusion, changeable C purlin roll forming machines represent a significant advancement in the production of structural steel components. Their flexibility, efficiency, and ability to minimize material waste make them a valuable asset in modern manufacturing processes. As the demand for versatile and reliable structural solutions continues to grow, these machines will play an increasingly important role in shaping the future of the construction industry.