Stud and Track Frame Forming Machines Transforming Metal Fabrication

In the realm of metal fabrication, the significance of precision machinery cannot be overstated. One of the standout innovations in this field is the stud and track frame forming machine. This advanced equipment has revolutionized the construction and manufacturing sectors by enhancing productivity, accuracy, and overall efficiency in the production of metal frames used in various applications.

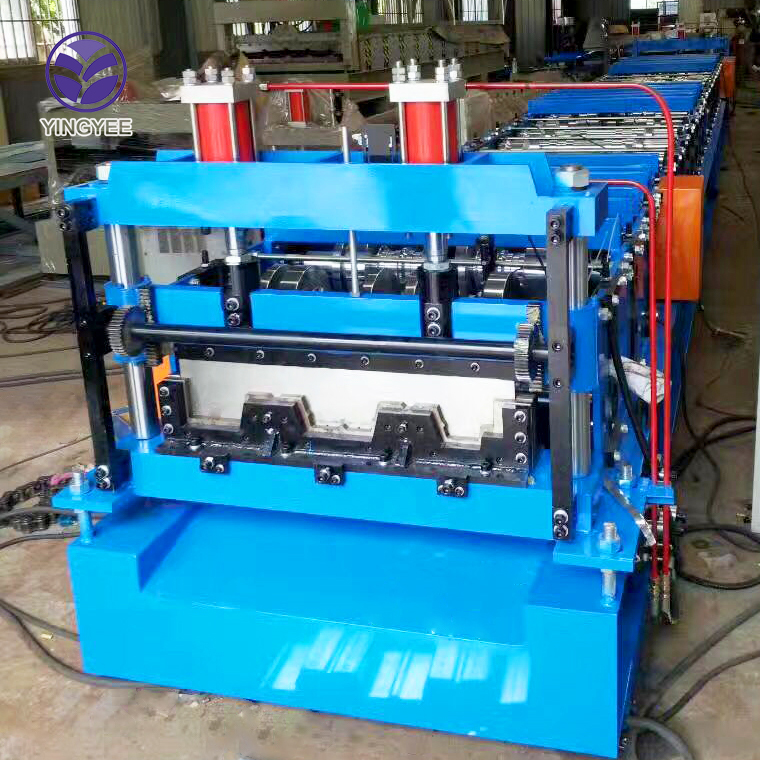

At the heart of the stud and track frame forming machine is its ability to create complex shapes and profiles from metal strips or coils. These machines operate through a series of rollers and dies that progressively shape the material into the desired form. The outcome is typically used in the construction of wall frameworks, ceilings, and even roof structures, which form the skeleton of numerous buildings, from residential homes to large commercial edifices.

One of the primary advantages of using a stud and track frame forming machine is the speed at which it can produce frames. Traditional methods often involve manual labor and less efficient techniques that can lead to inconsistencies and longer production times. In contrast, these machines are designed to operate at high speeds, allowing manufacturers to produce a significant quantity of frames in a fraction of the time. This increased efficiency not only boosts output but also reduces labor costs, making projects more financially viable.

Moreover, accuracy is another critical benefit of using stud and track frame forming machines. The precision engineered components ensure that each frame produced meets strict specifications, which is vital for structural integrity. In construction, using inaccurately formed frames can result in serious safety issues and costly remedial work. These machines minimize the likelihood of human error, ensuring that each piece is uniform and adheres to the required standards.

Versatility is another hallmark of stud and track frame forming machines. They can be configured to produce different profiles and sizes, accommodating various building designs and architectural requirements. This adaptability means that manufacturers can cater to a broad spectrum of projects without the need for multiple machines, thus optimizing their production capabilities.

Furthermore, advancements in technology have led to the incorporation of automation in these machines. Many modern stud and track frame forming machines are equipped with computerized controls and monitoring systems. This automation not only streamlines the production process but also allows for real-time adjustments and quality control. Operators can input specifications directly into the machine’s system, ensuring that every frame produced aligns perfectly with the intended design.

The environmental aspect of using stud and track frame forming machines should also be highlighted. These machines often utilize materials efficiently, reducing wastage significantly compared to traditional construction methods. As sustainability becomes an increasingly important consideration in the construction industry, the ability to produce high-quality frames with minimal waste positions these machines as a responsible choice.

In conclusion, stud and track frame forming machines are at the forefront of modern metal fabrication, providing unmatched speed, accuracy, and versatility. They play a crucial role in the construction industry, facilitating the production of essential components with efficiency and precision. As technology continues to evolve, we can expect even more advancements in this area, further enhancing the capabilities of stud and track frame forming machines. The future of construction looks promising, with these machines leading the charge towards a more innovative and sustainable industry.