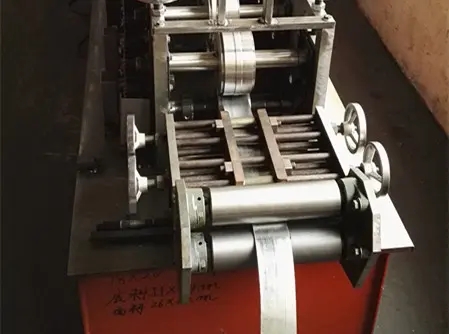

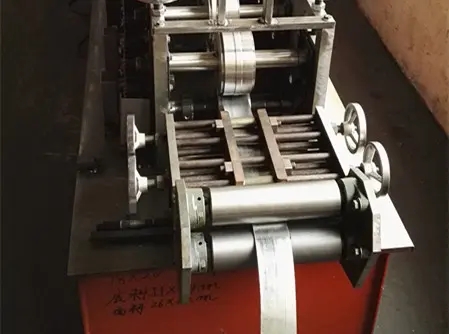

Metal Storage Rack / Upright Pillar Roll Forming Machine An Overview

In today's fast-paced industrial landscape, efficient storage solutions are crucial for businesses looking to optimize their space and improve operational efficiency. Metal storage racks have become a staple in warehouses and manufacturing facilities, providing a practical and robust way to organize inventory and tools. At the heart of metal storage rack production is the upright pillar roll forming machine, a vital piece of equipment that plays a significant role in shaping the structural components of these racks.

Understanding Metal Storage Racks

Metal storage racks serve multiple purposes, from storing raw materials to organizing finished products. Their design varies significantly, depending on the specific requirements of the industry. These racks are typically made of steel or other durable metals, allowing them to support substantial weights while maintaining structural integrity. The most critical component of these racks is the upright pillar, which bears the weight of horizontal beams and shelves.

The Role of Upright Pillar Roll Forming Machines

Upright pillar roll forming machines are designed to create the vertical components of metal storage racks with precision. The process involves feeding metal strips through a series of rollers, each shaping the material into the desired profile. This continuous transformation ensures a consistent and high-quality product that meets stringent safety standards.

The benefits of using roll forming machines in the production of upright pillars are numerous

1. Efficiency Roll forming is a highly efficient process, allowing manufacturers to produce large quantities of parts in a shorter time. This efficiency translates into reduced lead times for customers and ultimately lower production costs.

2. Precision The automated nature of roll forming machines ensures high levels of accuracy in dimensions and shapes, crucial for the structural integrity of metal racks. This precision reduces material waste and minimizes the need for additional finishing processes.

metal storage rack /upright pillar roll forming machine

3. Material Versatility Roll forming can accommodate various materials, including different grades of steel, which means manufacturers can tailor their offerings to meet specific customer needs.

4. Strength and Durability The strength of the finished product is enhanced through the roll forming process. As the metal is shaped, it often gains additional strength due to the cold-working effect, making the upright pillars even more robust.

5. Cost-Effectiveness The high production efficiency and low material waste associated with roll forming contribute to lower costs for manufacturers. This financial advantage allows them to offer competitive pricing to their clients.

Applications and Future Trends

The demand for metal storage racks is rising, particularly in sectors such as retail, logistics, and manufacturing. As businesses continue to expand and evolve, the need for scalable and flexible storage solutions will only increase. This demand drives innovation in machine technology and design capabilities.

Future trends in upright pillar roll forming machines may include the integration of smart technologies and automation. With the advent of Industry 4.0, more manufacturers are looking to incorporate IoT (Internet of Things) technologies into their processes. This could enhance machine monitoring and predictive maintenance, further improving efficiency and reducing downtime.

Moreover, as sustainability becomes a greater focus in manufacturing, companies are exploring ways to reduce energy consumption and material waste in their production processes. Roll forming machines are poised to benefit from these advancements, as their efficiency can align with eco-friendly practices.

Conclusion

In summary, the metal storage rack and the upright pillar roll forming machine are closely intertwined elements that play essential roles in modern industrial operations. Understanding the capabilities and advantages of these machines not only highlights their contribution to manufacturing efficiency but also underscores their significance in meeting the evolving demands of the marketplace. As technology continues to advance, we can expect the metal storage systems to become even more innovative, further enhancing productivity and operational effectiveness across industries.