Understanding Trapezoid Roof Sheet Forming Machines

Trapezoid roof sheet forming machines are essential tools in the modern construction and manufacturing industries. These machines play a vital role in producing trapezoidal steel sheets, which are widely used in roofing systems for both residential and commercial buildings. The unique geometry of trapezoidal sheets makes them particularly effective for water drainage, structural support, and durability.

What is a Trapezoidal Roof Sheet?

Trapezoidal roof sheets are characterized by their trapezoidal shape, which typically features two parallel sides of different lengths and two non-parallel angled sides. This design not only enhances the aesthetic appeal of buildings but also provides superior strength and stability compared to traditional flat roofing materials. The raised profiles of trapezoidal sheets allow for better water runoff, reducing the risk of water pooling and leakage.

The Role of Forming Machines

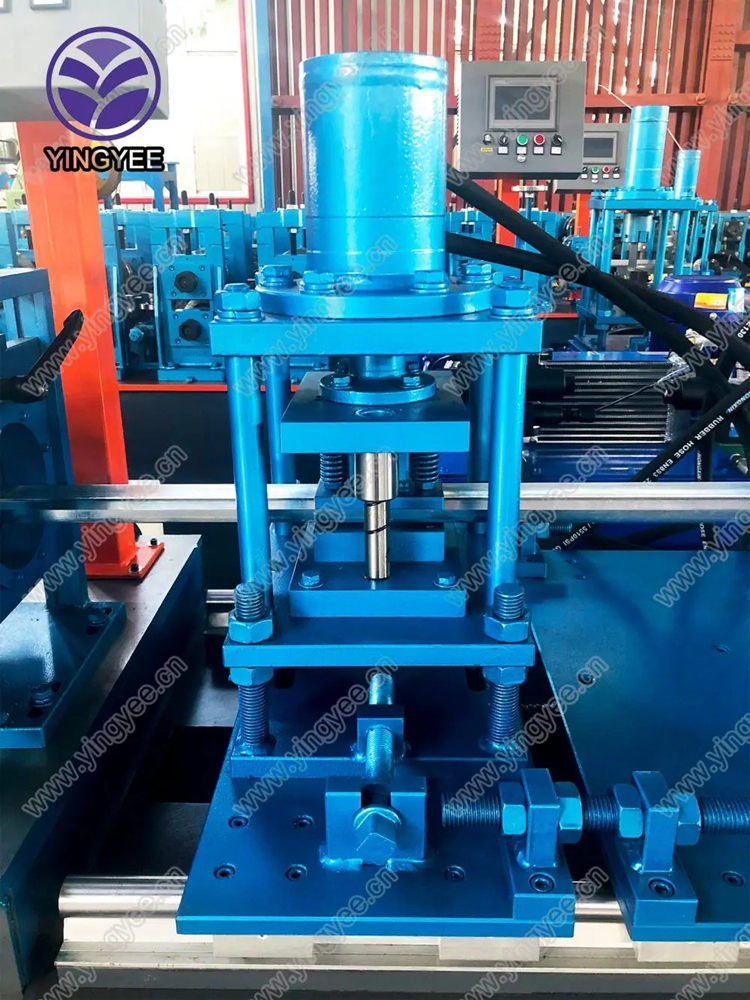

Trapezoid roof sheet forming machines are specialized equipment designed to fabricate these sheets from metal coils. The process generally begins with feeding a flat coil of metal into the machine. The machine then utilizes a series of rollers that shape the metal into the desired trapezoidal profile. This continuous forming process allows for high efficiency and consistency, which are critical for large-scale production.

Types of Trapezoid Roof Sheet Forming Machines

There are several types of trapezoid roof sheet forming machines available, ranging from manual systems for small workshops to fully automated systems for large manufacturing plants. Each machine varies in terms of capability, speed, and technological features. Advanced models may include computer numerical control (CNC) systems, which enhance precision and allow for intricate designs to be milled directly into the sheets during production.

1. Manual Forming Machines Ideal for small projects or shops, these machines require operators to manually adjust settings and feed materials, making them less efficient for large runs.

2. Semi-Automatic Machines These machines combine manual operation with automatic processes to improve efficiency while still requiring some human intervention.

3. Fully Automatic Machines These advanced machines use PLC (Programmable Logic Controller) systems to control all aspects of production. Operators can input specifications via a user-friendly interface, and the machine autonomously handles the entire forming process, allowing for rapid production and minimal errors.

Advantages of Using Trapezoid Roof Sheet Forming Machines

1. Speed and Efficiency Automated forming machines can produce large quantities of trapezoidal sheets in a fraction of the time that manual processes would require.

2. Consistency and Quality These machines ensure that every sheet produced meets rigorous quality standards, resulting in uniform products that fit better during installation.

3. Cost-Effective Although initial investment in automated machines may be high, the long-term savings achieved through increased production efficiency and reduced labor costs make them economically advantageous.

4. Customization Advanced machines allow for custom designs and varied dimensions, catering to the specific needs of different projects.

Conclusion

In summary, trapezoid roof sheet forming machines are invaluable in the production of high-quality roofing materials. Their ability to efficiently manufacture durable and appealing sheets contributes significantly to the construction industry. As technology continues to advance, these machines are expected to become even more efficient and versatile, further revolutionizing the way roofing materials are produced and used around the world. With the ever-growing demand for sustainable and innovative building solutions, investing in a trapezoid roof sheet forming machine is a forward-thinking decision for manufacturers and contractors alike.