The Evolution and Advantages of Composite Floor Deck Roll Formers

In the realm of modern construction, efficiency and durability are paramount. As demands for faster, safer, and more economical building solutions rise, innovations such as composite floor deck roll formers have emerged to meet these needs. These machines play a crucial role in the production of metal decking systems that provide structural support while minimizing weight—a significant advantage in contemporary construction projects.

Composite floor decks are an exceptional choice in building construction due to their enhanced strength and reduced overall weight when compared to traditional concrete alternatives. They consist of a series of steel panels that are integrated with concrete, providing a composite action that utilizes the best properties of both materials. By combining the tensile strength of steel and the compressive strength of concrete, these floor decks achieve greater load-bearing capabilities while being economical in terms of material usage.

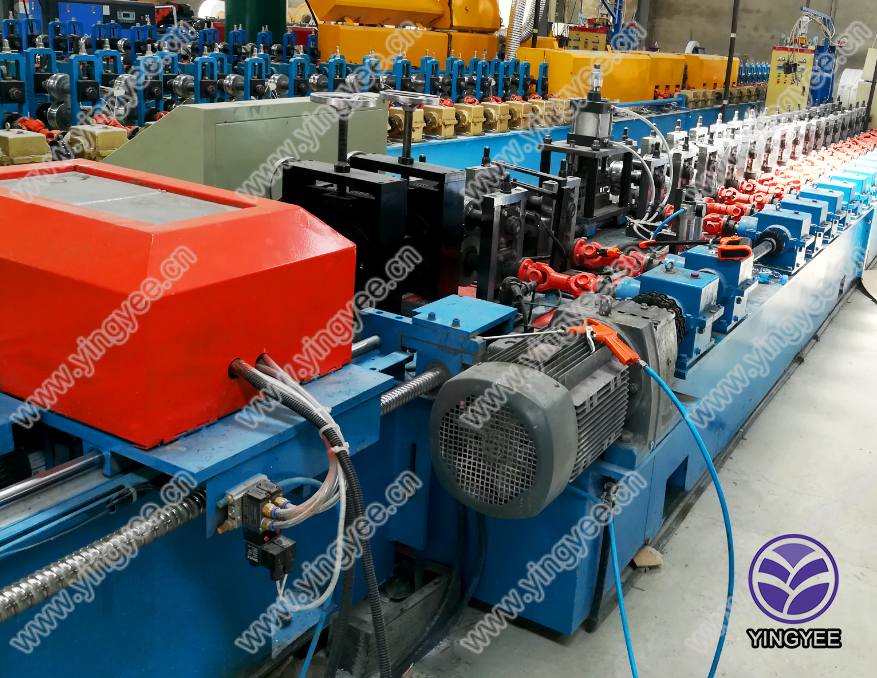

One of the primary innovations that has accelerated the use of composite floor decking is the development of roll forming technology. Roll formers are machines designed to shape metal into specific profiles by feeding sheets through a series of rollers. This process ensures precision and consistency in the manufacturing of floor deck systems. The use of roll formers not only streamlines production but also reduces waste, making it a more sustainable choice for manufacturers.

The operational efficiency of composite floor deck roll formers comes from their ability to produce long, continuous sheets of decking that can be easily transported and installed on-site. This capability reduces the time and labor costs associated with installation, enabling contractors to complete projects more quickly. In an industry where time is money, the speed and efficiency of roll forming technology provide a distinct advantage over conventional decking methods.

Moreover, the adaptability of roll formers allows manufacturers to create custom profiles to meet the specific requirements of different projects. Adjustments can be made to the machine settings to produce varying thicknesses and widths of decking, accommodating diverse structural needs and ensuring compatibility with various architectural designs. This versatility enhances the appeal of composite floor decks—building owners can achieve their desired aesthetic without compromising on structural integrity.

Another noteworthy benefit of using composite floor deck roll formers is their contribution to sustainability. With growing concerns about the environmental impact of construction practices, the ability to reduce material waste and optimize resource use is critical. The roll forming process minimizes excess material, and the longevity of composite decks means less frequent replacements, further lowering the environmental footprint of a building project.

Additionally, the combination of steel and concrete in composite floor systems enhances fire resistance, making these structures safer compared to traditional wood-based systems. This inherent safety feature is increasingly important in today’s building codes, as more jurisdictions implement stringent fire safety regulations.

In conclusion, composite floor deck roll formers represent a significant advancement in construction technology. Their efficiency, versatility, and sustainability benefits make them an essential tool in modern construction projects. As the industry continues to evolve, embracing such innovations will be key to meeting the challenges of building demands and creating safe, durable, and environmentally friendly structures. The future of construction lies in the integration of traditional practices with cutting-edge technology, and composite floor deck roll formers are at the forefront of this transformation.