Acoustic barriers are essential for reducing noise pollution in urban and industrial areas. These barriers are often made of metal sheets that need to be bent into specific shapes to effectively block sound waves. To achieve this, a cold bending machine is used to bend the metal sheets without applying heat, ensuring the integrity of the material is not compromised.

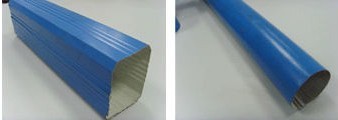

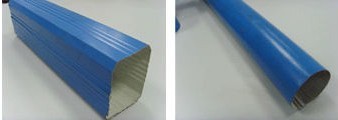

The acoustical barrier cold bending machine is a versatile piece of equipment that can handle a variety of metal sheet thicknesses and widths. It operates by using a series of rollers and bending tools to manipulate the metal sheet into the desired shape. The machine's precision control system allows for uniform bends and accurate measurements, ensuring the final product meets the required specifications for optimal sound absorption.

One of the key advantages of using a cold bending machine for acoustical barrier production is the efficiency and cost-effectiveness it offers. Unlike traditional methods that involve heating the metal sheet for bending, cold bending eliminates the need for additional equipment and reduces energy consumption. This not only saves time and labor costs but also results in a more environmentally friendly production process.

Moreover, the cold bending process ensures the structural integrity of the metal sheet is maintained acoustical barrier cold bending machine

acoustical barrier cold bending machine. Heat bending can weaken the material and potentially lead to cracking or deformation, compromising the effectiveness of the acoustical barrier. By using a cold bending machine, the metal sheet retains its strength and durability, guaranteeing a long-lasting and reliable barrier for sound reduction.

In addition to its efficiency and durability, the acoustical barrier cold bending machine also offers flexibility in design and customization. Whether it's a straight, curved, or angled barrier, the machine can accommodate various bending requirements to meet the specific needs of different projects. This adaptability allows for creative and innovative designs that not only serve their acoustic purpose but also enhance the aesthetic appeal of the surrounding environment.

Overall, the acoustical barrier cold bending machine plays a crucial role in the production of high-quality sound barriers that effectively reduce noise pollution. Its efficiency, cost-effectiveness, durability, and flexibility make it an indispensable tool for urban planners, architects, and engineers looking to create quieter and more livable spaces. By investing in advanced technology like the cold bending machine, communities can embrace sustainable solutions for sound management and improve the quality of life for their residents.