Understanding Prepainted Galvanized Steel Coils A Comprehensive Overview

Prepainted galvanized steel coils (PPGI) have become increasingly vital in various industries thanks to their durability, aesthetic appeal, and versatility. This article delves into the characteristics, benefits, applications, and production processes of prepainted galvanized steel coils, shedding light on why they have gained popularity in modern manufacturing and construction.

What is Prepainted Galvanized Steel?

Prepainted galvanized steel is a type of steel that has been coated with a layer of zinc to protect it from corrosion and then painted or coated with polymers to enhance its appearance and improve its resistance to environmental factors. The prepainted aspect indicates that the steel is coated before fabrication, giving it a uniform finish and ensuring a cleaner manufacturing process during installation.

Characteristics of PPGI

1. Corrosion Resistance The galvanized layer acts as a barrier to moisture, preventing rust and corrosion. This characteristic is crucial, especially in environments that experience high humidity or exposure to chemicals.

2. Aesthetic Appeal The prepainting process allows for a wide range of colors and finishes, making PPGI an attractive choice for architectural applications. This capability helps meet the aesthetic demands of modern design while maintaining structural integrity.

3. Durability PPGI is designed to withstand harsh weather conditions, including sun exposure, wind, and rain. The coatings used are often UV resistant, ensuring that the colors remain vibrant over time.

4. Ease of Fabrication Prepainted coils can be easily cut and shaped into various forms without chipping or peeling, making them ideal for a range of manufacturing applications.

Benefits of Prepainted Galvanized Steel Coils

1. Cost-Effective Despite the initial investment, the long-term durability and low maintenance requirements of PPGI can lead to significant cost savings over time. Reduced frequency of replacement and maintenance decreases operational costs.

2. Sustainability Galvanized steel is recyclable, contributing to sustainability in construction and manufacturing. Using durable materials reduces waste and supports eco-friendly practices.

3. Time Efficiency Employing PPGI in construction and manufacturing can accelerate project timelines. Since the product comes pre-finished, there is no need for additional painting or coating after fabrication, saving both time and labor costs.

4. Wide Range of Applications From roofing and siding in construction to appliances and furniture in manufacturing, the versatility of PPGI makes it suitable for various applications across multiple industries.

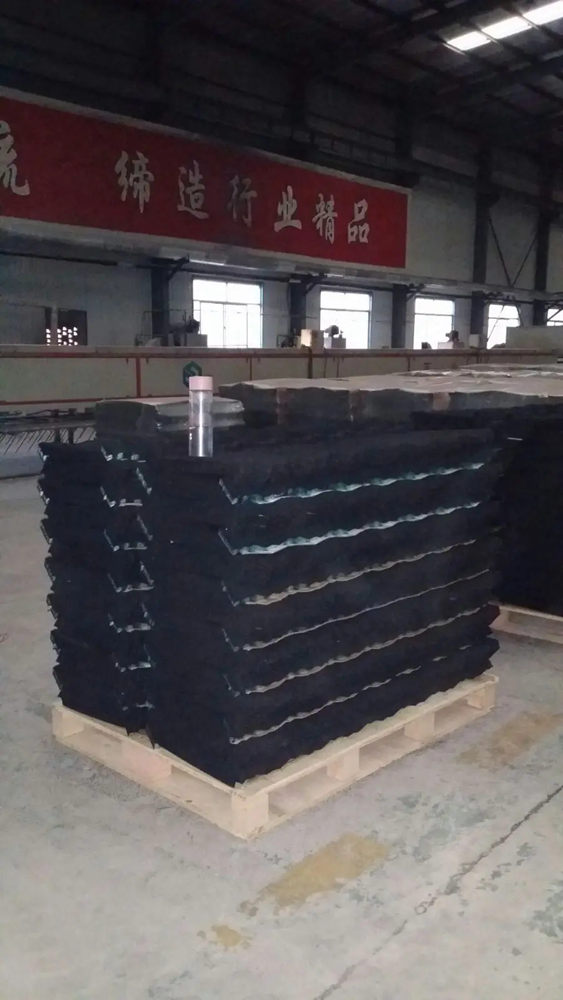

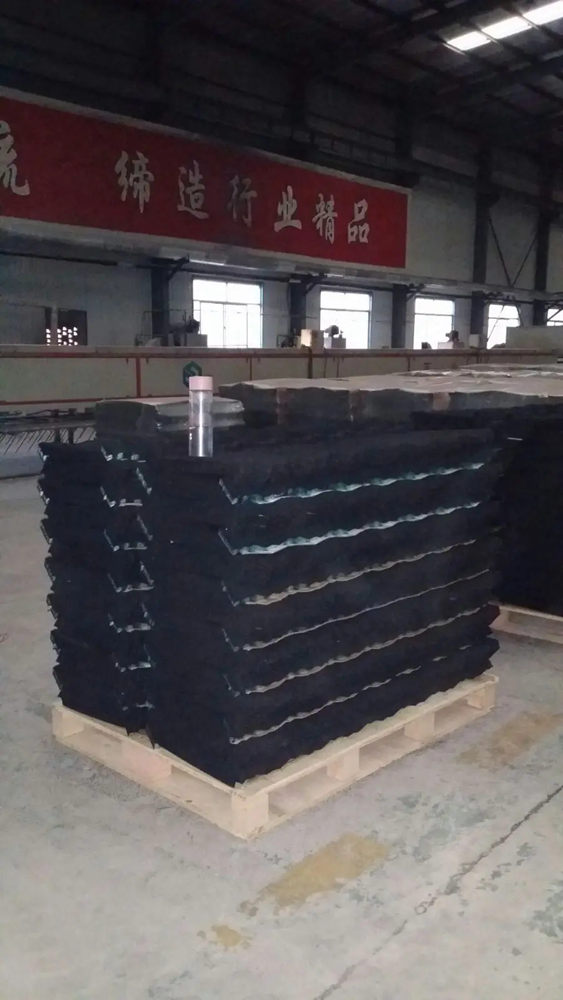

600-1500 prepainted galvanized steel coils

Applications of PPGI

Prepainted galvanized steel coils are used in several sectors, including

- Construction In roofing, wall cladding, and framing systems, PPGI provides both structural support and aesthetic appeal.

- Automotive The automotive industry utilizes PPGI for various components, which benefit from reduced weight and increased resistance to corrosion.

- Home Appliances Many household appliances, including refrigerators, washing machines, and air conditioners, are made from PPGI due to its durability and ease of cleaning.

- Furniture Modern furniture often features components made from PPGI, enhancing both style and longevity.

Production Process

The production of prepainted galvanized steel coils involves several steps

1. Steel Preparation The steel substrate is cleaned to remove any contaminants that could affect adhesion.

2. Galvanization The prepared steel is coated with a layer of zinc through hot-dip galvanization or electrogalvanization processes.

3. Coating Once galvanized, the steel is painted in a controlled environment. Multiple layers of paint can be applied, including primers and topcoats, to increase durability and finish quality.

4. Drying and Curing The coated steel then goes through drying and curing processes, ensuring that the paint adheres well and provides maximum protection.

Conclusion

In summary, prepainted galvanized steel coils represent a significant advancement in materials technology. Their combination of functionality, aesthetic appeal, and environmental sustainability makes them a preferred choice across numerous industries. As building practices and consumer preferences continue to evolve, PPGI's role in modern construction and manufacturing will likely expand further, paving the way for innovative applications and solutions.