The Advantages of a 1mm-3mm Cut to Length Production Line High Production Speed and Best Quality

In the fast-paced world of manufacturing, efficiency and quality are paramount. For industries that rely on materials such as metal, plastic, or paper, cut-to-length production lines have become essential. Specifically, systems designed to cut materials ranging from 1mm to 3mm are gaining popularity due to their ability to provide high production speeds while maintaining exceptional quality standards.

Understanding Cut-to-Length Production Lines

A cut-to-length production line is a manufacturing system designed to process continuous rolls of material into predetermined lengths. As opposed to traditional methods that may involve slower manual cutting or older technologies, modern cut-to-length lines are automated, allowing for precise, quick, and consistent processing. This automation is invaluable for operation efficiency, especially when dealing with materials that require exact dimensions, such as components in the automotive, aerospace, and electronics industries.

High Production Speed

One of the most significant advantages of a 1mm-3mm cut-to-length production line is its high production speed. Modern systems are engineered to operate at rapid rates, often capable of processing thousands of meters of material per hour. This capability is particularly critical in scenarios where time is of the essence, such as when fulfilling large orders or managing tight deadlines.

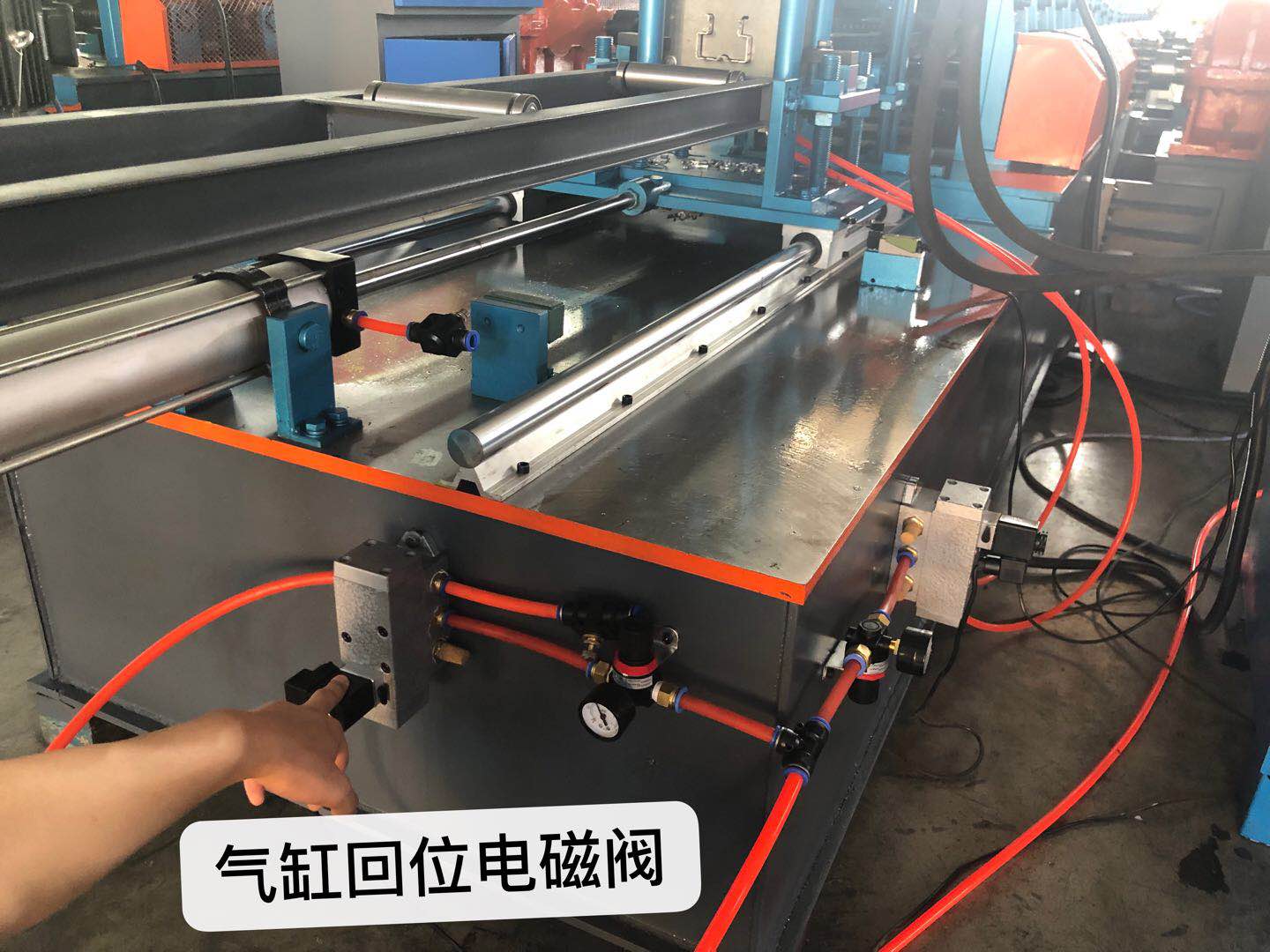

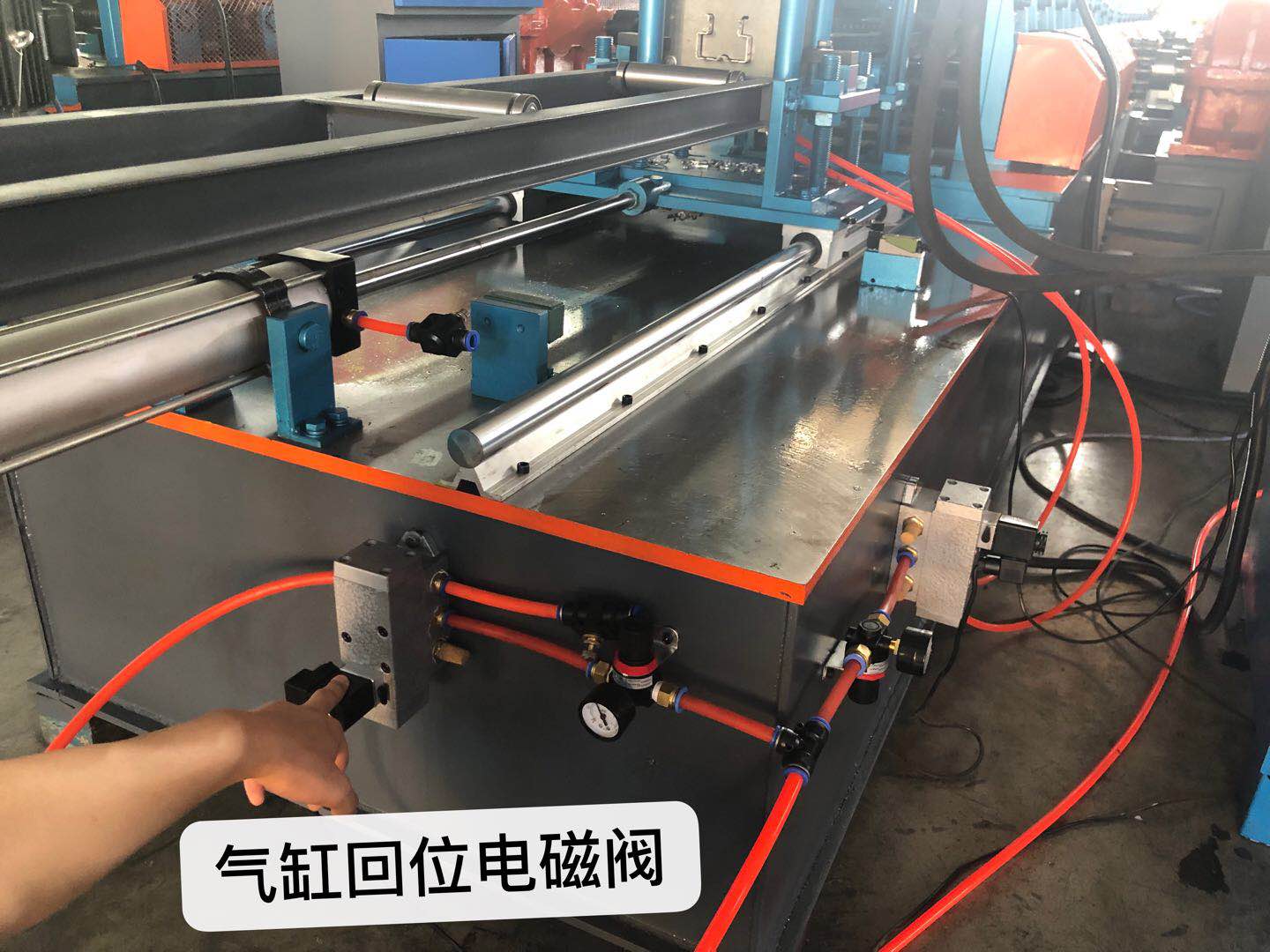

High-speed production is achieved through various means, including advanced feeding systems, precision cutting tools, and sophisticated control software. These technologies allow the machine to maintain a continuous workflow, minimizing downtime for adjustments or restarts. The result is a streamlined operation that can meet the demands of high-volume production without compromising quality.

Best Quality Assurance

In addition to speed, maintaining the best quality is crucial in manufacturing. A 1mm-3mm cut-to-length production line excels in this area as well, employing cutting-edge technology to ensure precision and consistency at every stage of the process. The equipment used in these lines is often equipped with sensors and monitoring systems that constantly check for accuracy and alignment.

1mm-3mm cut to length production line high prodiction speed best quality

Quality assurance begins at the material feeding stage, where systems are designed to handle materials gently, ensuring they are not damaged before cutting. Once the material is fed into the cutting area, high-precision blades ensure a clean cut with minimal burr or distortion. This precision is essential for applications where the dimensions must meet strict tolerances.

Reduced Waste and Cost Efficiency

Another aspect of achieving high quality and production speed is the reduction of scrap and waste. Cut-to-length production lines are designed with optimized cutting plans that minimize excess material. For instance, when cutting strips for manufacturing, the line can be programmed to ensure that the dimensions are efficient and conducive to the least amount of waste possible. This not only saves costs associated with material loss but also aligns with sustainable manufacturing practices.

Versatility and Customization

Manufacturers today often face diverse customer needs, requiring flexibility in their production processes. A 1mm-3mm cut-to-length line typically offers various customization options, allowing for adjustments to both the length and the speed of production. This versatility means that manufacturers can swiftly adapt to changes in market demand without needing to invest in entirely new systems.

Furthermore, modern production lines can integrate with existing systems, creating a cohesive operation that may involve other processes such as shearing, slitting, or stacking. This integration enhances overall efficiency and productivity, creating a seamless workflow from start to finish.

Conclusion

In conclusion, the implementation of a 1mm-3mm cut-to-length production line provides manufacturers with an array of benefits, including high production speeds and excellent quality assurance. As industries evolve and demand for precision and efficiency rises, these advanced production lines become critical components in maintaining competitiveness. The combination of speed, quality, waste reduction, and customization makes these systems an invaluable asset for any manufacturer aiming for excellence in their product output. Investing in such technology is not merely an operational decision; it is a strategic move toward sustained growth and success in the modern manufacturing landscape.