Understanding 100-600% Cable Tray Machine

The modern industrial landscape is characterized by rapid technological advancements, especially in manufacturing processes that enhance efficiency and productivity. One notable innovation in this field is the 100-600% cable tray machine, which is designed to produce a wide range of cable trays with high precision and varying specifications. This article will explore the features, benefits, and significance of cable tray machines in contemporary manufacturing.

What is a Cable Tray Machine?

A cable tray machine is a specialized piece of equipment used to manufacture cable trays that support and organize electrical cables in various settings, including commercial buildings, factories, and data centers. These trays are essential for electrical installations as they facilitate the orderly arrangement of cables, minimizing clutter and ensuring safety. The 100-600% cable tray machine refers to its capacity to enhance production efficiencies by allowing for a significant increase in output, ranging from 100% to 600%, compared to standard machines.

Key Features of the 100-600% Cable Tray Machine

One of the standout features of the 100-600% cable tray machine is its automation. Modern machines are equipped with advanced technology, such as programmable logic controllers (PLCs) and computer numerical control (CNC) systems. These components allow for precise control over the manufacturing process, reducing human error and ensuring consistent product quality.

Another hallmark of this machine is its versatility. It can produce cable trays in various sizes and materials, including steel, aluminum, and fiberglass, accommodating different project requirements. The flexibility to switch between different designs and configurations without requiring extensive downtime is a significant advantage for manufacturers.

Moreover, the machine's high-speed operation distinguishes it from traditional cable tray manufacturing equipment. By maximizing production rates, companies can meet the increasing demand for cable trays in a timely manner, enhancing their competitive advantage in the market.

Benefits of Using the 100-600% Cable Tray Machine

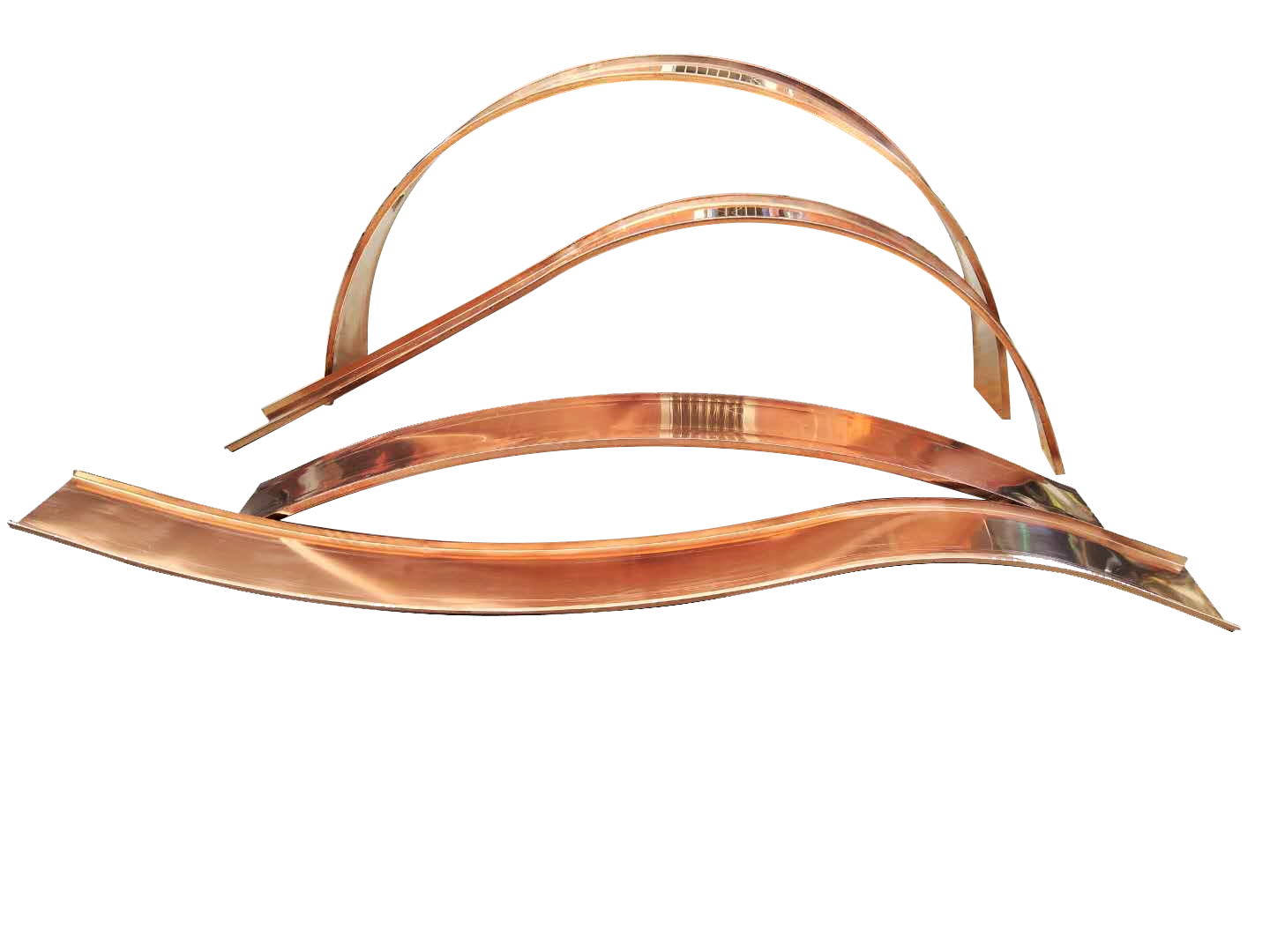

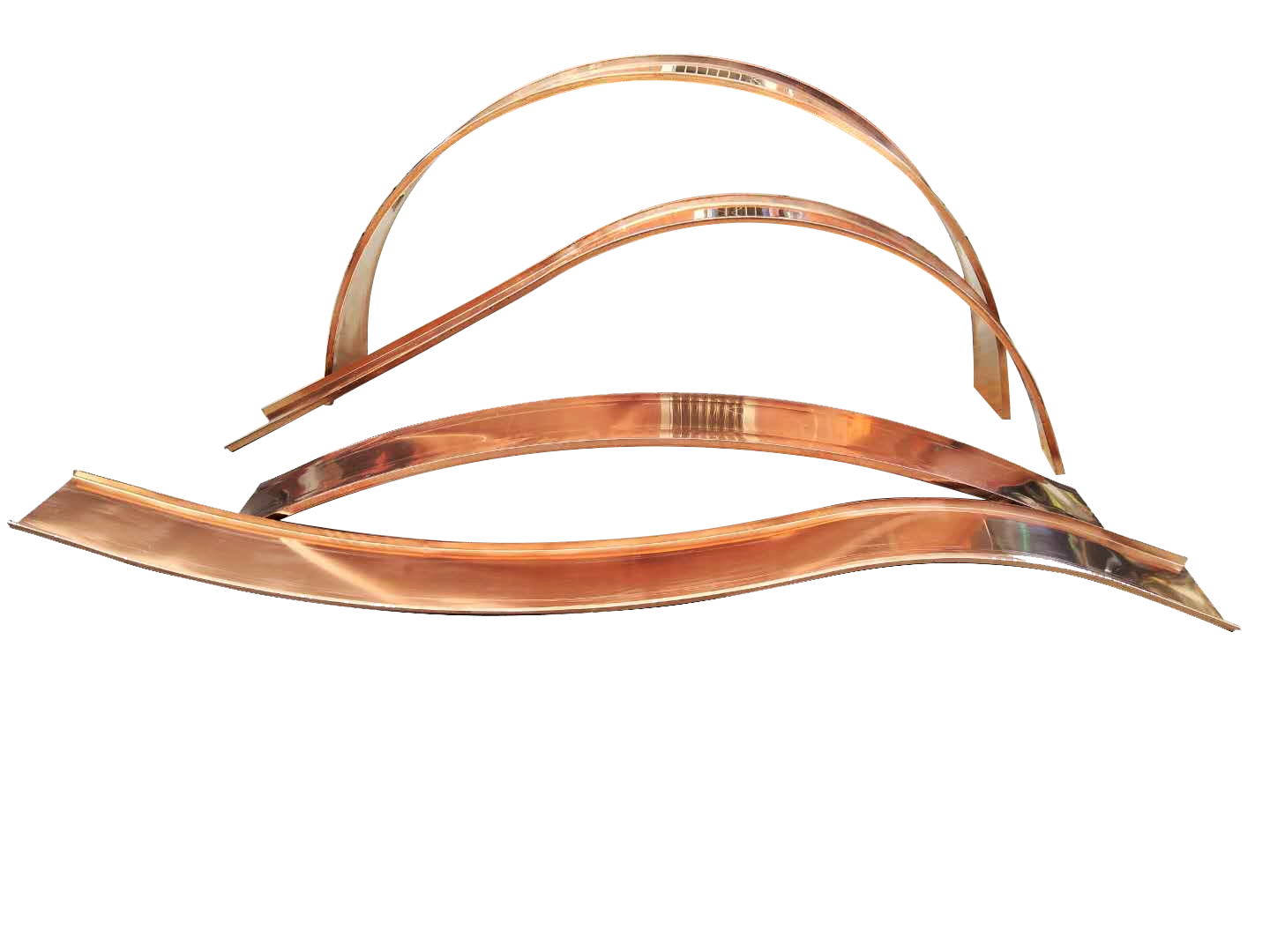

100-600 cable tray machine

The implementation of a 100-600% cable tray machine offers numerous advantages. Firstly, the increased production capacity allows manufacturers to fulfill larger orders more efficiently, reducing lead times and improving customer satisfaction. Faster production cycles mean that businesses can respond swiftly to market changes and demands, which is critical in today’s fast-paced environment.

Secondly, the consistency provided by automated processes ensures high-quality products with minimal defects. This reliability can bolster a manufacturer's reputation and lead to repeat business and referrals. In an industry where safety and compliance are paramount, producing high-quality cable trays is essential.

Thirdly, the reduction in labor costs is noteworthy. While initial investments in such machines can be significant, the decreased need for manual labor can lead to long-term savings. Automating production processes allows companies to allocate their human resources more effectively, focusing on areas such as design and customer service instead.

The Significance of Cable Tray Machines in Industries

The role of cable tray machines extends beyond mere manufacturing; they are integral to various industries, including construction, telecommunications, and energy. As infrastructure projects grow in complexity and size, the demand for efficient cable management solutions continues to rise. The ability of the 100-600% cable tray machine to produce large quantities of cable trays ensures that industries can maintain organized and safe electrical installations.

Furthermore, with the increasing push towards sustainability, manufacturers are exploring eco-friendly materials and processes. Advanced cable tray machines can incorporate recycled materials and facilitate cleaner production methods, aligning with global sustainability goals.

Conclusion

The 100-600% cable tray machine represents a significant advancement in the manufacturing sector, combining efficiency, versatility, and quality. By automating the production of cable trays, these machines play a crucial role in supporting the infrastructure that powers our modern world. With the need for effective cable management solutions growing, investing in such technology is not just beneficial but essential for manufacturers aiming to thrive in an ever-evolving market. As industries continue to expand and evolve, the role of cable tray machines will undoubtedly become even more critical in enabling connectivity and supporting technological advancements.