Precision Slitting Lines: Unlock Efficiency from Your Coil Material

Transform Master Coils into Precision Strip with Unmatched Accuracy

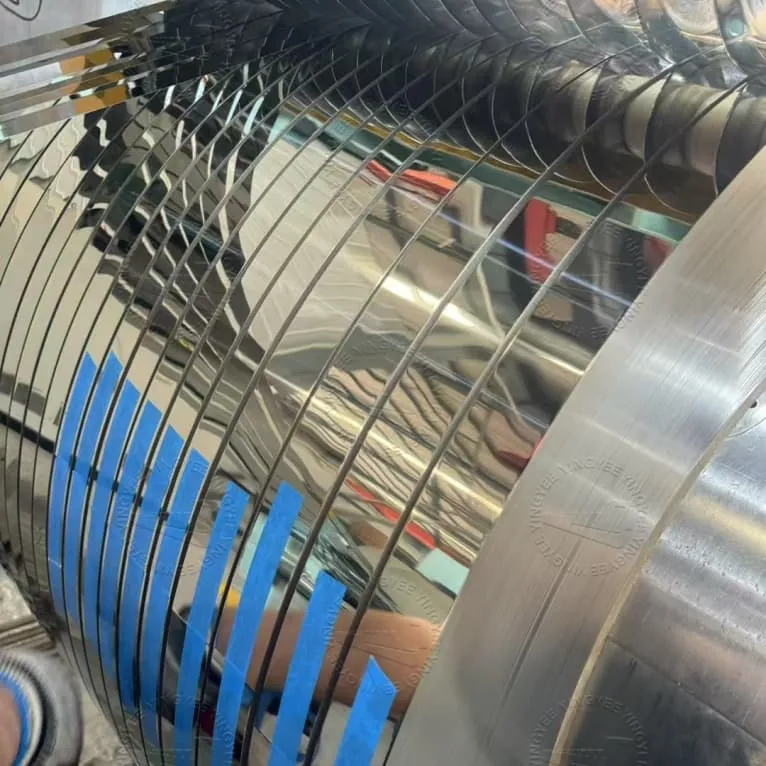

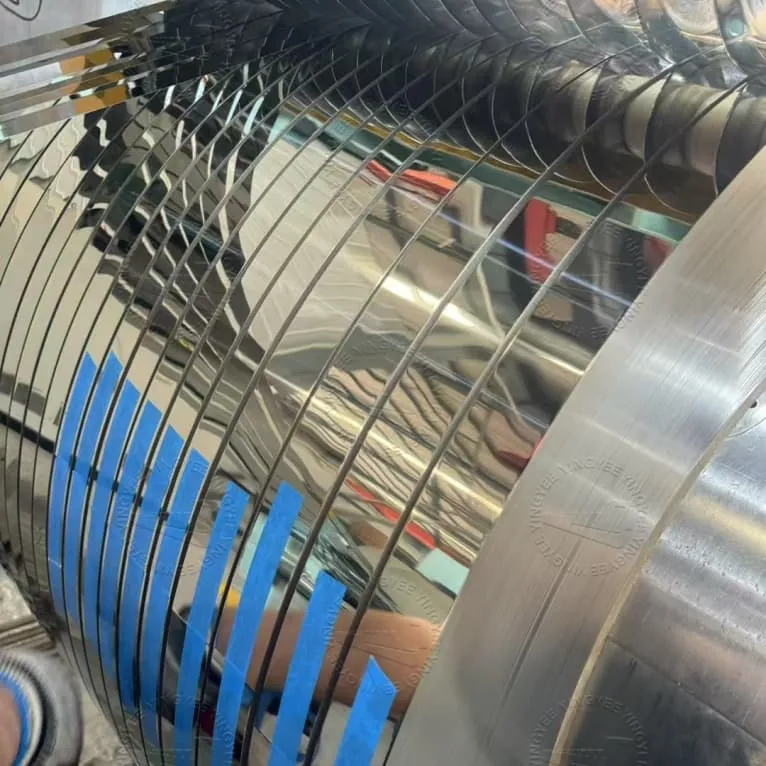

Our high-performance slitting lines are engineered for one critical mission: to efficiently and accurately convert your wide master coils into multiple narrow strips of exact specification. Designed for robust, continuous operation, they are the cornerstone of a streamlined and profitable metal processing workflow, delivering superior edge quality, minimal material waste, and maximum uptime.

Engineered for Superior Performance & Reliability

-

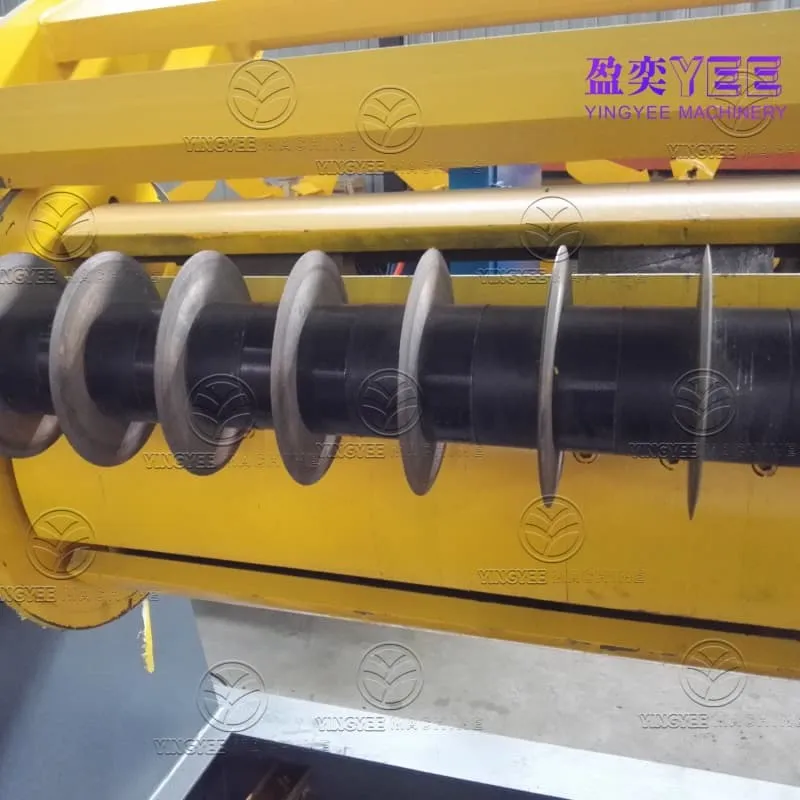

Uncompromising Precision: Achieve perfectly clean, burr-free edges and consistently exact strip widths. Our rigid slitting head, precision arbors, and advanced guidance systems ensure every strip meets the most stringent quality standards for your downstream processes.

-

Maximized Productivity & Yield: From automatic coil loading and threading to high-speed slitting and tight, uniform rewinding, our lines are built for speed. Quick-change tooling and intuitive controls drastically reduce changeover times, maximizing your output and material yield from every coil.

-

Operational Safety & Ease of Use: Your team's safety is our priority. Integrated safety guards, comprehensive emergency stop systems, and automated material handling create a secure working environment while simplifying operation.

-

Proven Durability & Low Maintenance: Built with heavy-duty components and a robust frame, our slitting lines are designed for long-term reliability in the most demanding environments, minimizing maintenance requirements and total cost of ownership.

-

The Ideal Solution for a Wide Range of Industries:

-

Automotive Component Manufacturing

-

Electronics & Appliance Production

-

Construction & Building Materials

-

Furniture, HVAC, and beyond.