decoiler:Manual 5 tons

1: Max width of raw material :1250mm

2: Capacity: 5000kgs

3: Inner diameter of coil: 450-600mm

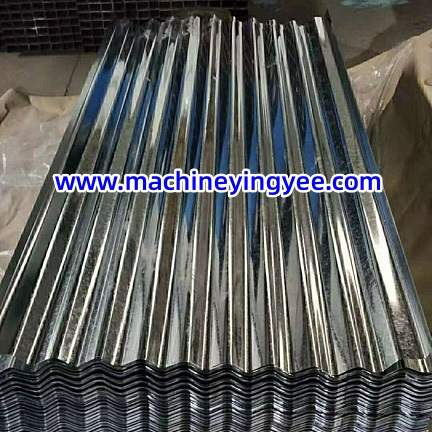

Roll forming machine

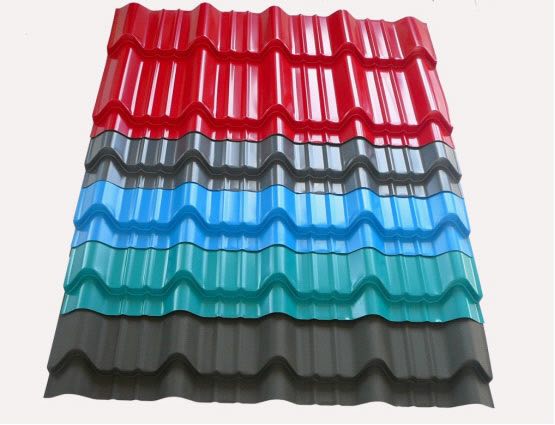

1.Matching material:PPGI/GI/Aluminium

2.Material thickness:0.3-0.8mm

3.Power:5.5kw

4.Forming speed:3m/min

5.The width of the plates:according to the drawings

6.Input leveling equipment:adjustable as photos.

7.Roll stations:16 rollers

8.Shaft Material and diameter:materialis45#steel ¢75mm,

9.Tolerance:10m±1.5mm

10.Way of drive:chain drive

11.Controlling system:PLC

12.Voltage: 380V, 50 Hz, 3Phase (According to the customer)

13.Material of forming rollers:45#steel heat treatment and chromed

14.Side plate:steel plate with Chromed.

Cutting(hydraulic guide)

1.Cutting motion: The main machine automatically stops and then cutting. After

the cutting, the main machine will automatically start.

2.Material of blade: Cr12 mould steel with quenched

treatment58-62℃

3.Length : Automatic length measuring

4.Tolerance of length: 10+/- 1.5mm

PLC control system

1.Voltage, Frequency, Phase: 380V, 50 Hz, 3Phase

2.Automatic length measurement:

3.Automatic quantity measurement

4.Computer used to control length & quantity. Machine will automatically cut to

length and stop when required quantity is achieved

5.Length inaccuracy can be amended easily

6.Control panel: Button-type switch and touch screen

7.Unit of length: millimeter (switched on the control panel)