YingYee Machinery's Highway Guardrail Roll Forming Machine represents more than manufacturing equipment - it's a complete solution including profile design consultation, material selection guidance, and production line optimization. Our machines can be customized with automatic marking systems, real-time thickness monitoring, and remote performance diagnostics.

Backed by our international service network and continuous safety standard updates, this technology enables manufacturers to participate in critical infrastructure projects worldwide. Whether supplying government tenders or private developments, our Highway Guardrail Roll Forming Machines deliver the precision, reliability and capacity needed to make roads safer for all.

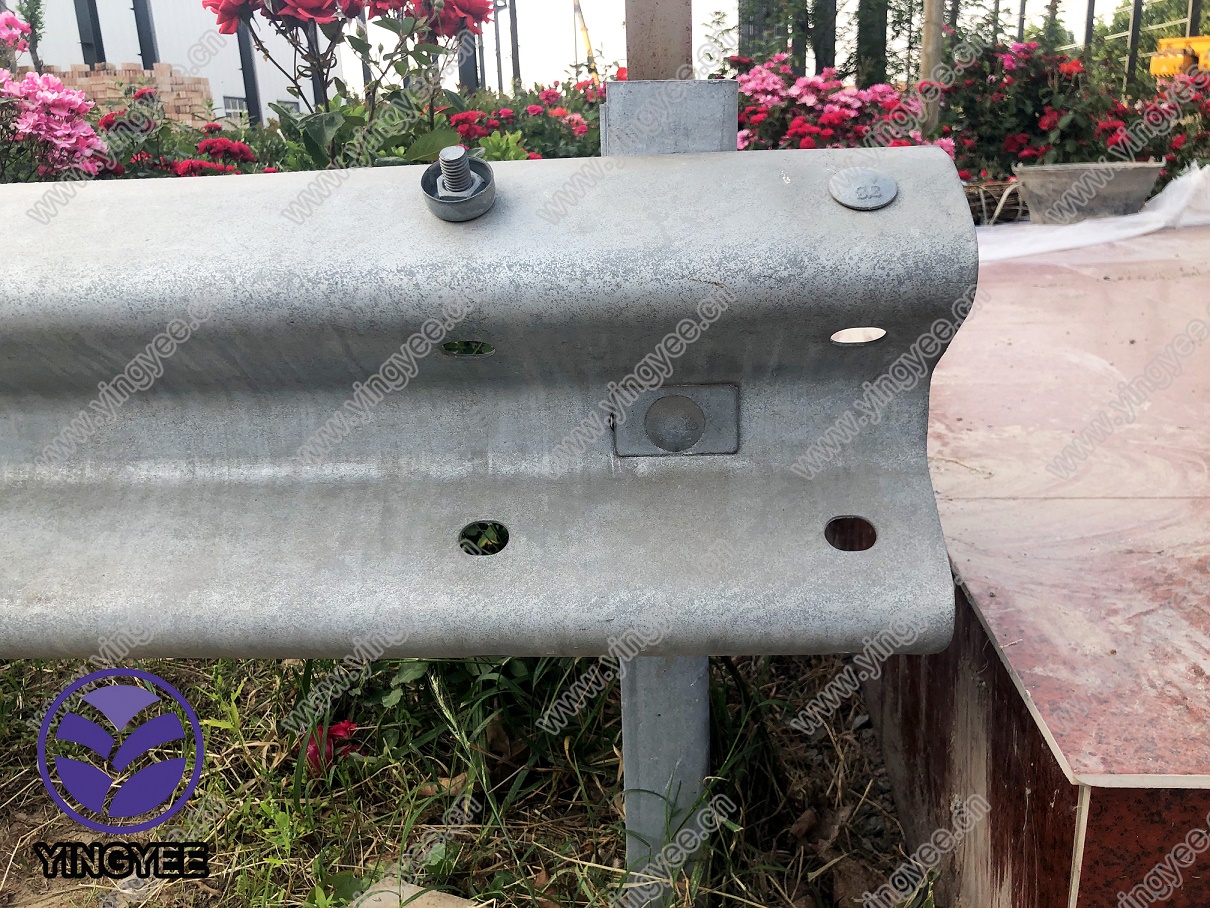

Guardrail roll forming machine for two waves and three waves as option, the thickness for the guardrail highway roll forming machine is from 2mm to 4mm.

Kaks lainet ja kolm lainet on valikulised. Maksimaalne paksus on 4 mm.

In the critical field of transportation infrastructure, safety and durability cannot be compromised. YingYee Machinery's Highway Guardrail Roll Forming Machine represents the pinnacle of roadside barrier manufacturing technology, engineered to produce guardrails that meet the most stringent international safety standards. This advanced system transforms high-strength steel coils into precisely formed protective barriers that save lives on highways worldwide.

Our Highway Guardrail Roll Forming Machine excels through its heavy-duty forming technology, capable of processing thick-gauge steel up to 4.5mm while maintaining tight dimensional tolerances. The intelligent control system automatically adjusts parameters for different guardrail profiles, from standard W-beam to thrie-beam configurations. With production speeds reaching 8-15 meters per minute and continuous operation capability, this machine delivers the high-volume output required for major infrastructure projects while ensuring consistent quality across every meter produced.

The production process of our Highway Guardrail Roll Forming Machine begins with heavy-duty coil handling, capable of processing large-diameter coils of high-tensile steel. The material first passes through a powerful leveling system that removes all coil memory, ensuring perfectly flat input material. As the steel progresses through the 16-24 forming stations, it gradually transforms into the distinctive guardrail profile with millimeter precision.

Mid-process, the computer-controlled punching station creates the precisely spaced bolt holes required for assembly. The final forming stages perfect the critical roll shape that determines the guardrail's energy-absorbing characteristics. An automated stacking system then organizes the finished guardrails with protective separators, ready for galvanizing or direct shipment to construction sites.

The safety barriers produced by our Highway Guardrail Roll Forming Machine protect roads and highways across every continent. In national highway systems, these barriers mitigate the severity of run-off-road accidents. Mountainous terrain projects rely on their strength for median dividers on winding roads. Even urban expressways use these guardrails to separate opposing traffic flows and protect roadside structures.

The machine's versatility extends beyond traditional roads - airport runways utilize these barriers for perimeter security, while race circuits install them for driver protection. With increasing global investment in road safety modernization, the demand for high-quality roll formed guardrails continues to grow exponentially.