YingYee Machinery's Electric Box Roll Forming Machine represents more than just capital equipment - it's a comprehensive manufacturing solution that includes application engineering support, tooling design services, and production line optimization. Our machines can be customized with powder coating integration, laser marking systems, and automated packaging lines to create complete turnkey solutions.

Backed by our global service network and commitment to continuous innovation, investing in our technology ensures manufacturers stay ahead in the rapidly evolving electrical enclosure market. From small electrical workshops to large OEMs, our Electric Box Roll Forming Machines deliver the precision, efficiency, and smart manufacturing capabilities needed to succeed in today's competitive landscape.

Ukukhiqizwa okuzenzakalelayo kwe-Electric DIN Rail, sebenzisa umucu wamagalani ukukhiqiza.

Izimbobo zokusika nokubhoboza okuzenzakalelayo, umsebenzi owodwa uyasebenza

Ubukhulu bezinto ezibonakalayo buyi-0.8-1.0mm, 1.0-1.2mm, 1.2-1.5mm. Ugqinsi ngalunye lubanga umshini owodwa. Isakhiwo se-Torrist, uhlangothi olulodwa lunganyakaza futhi lulungise ububanzi

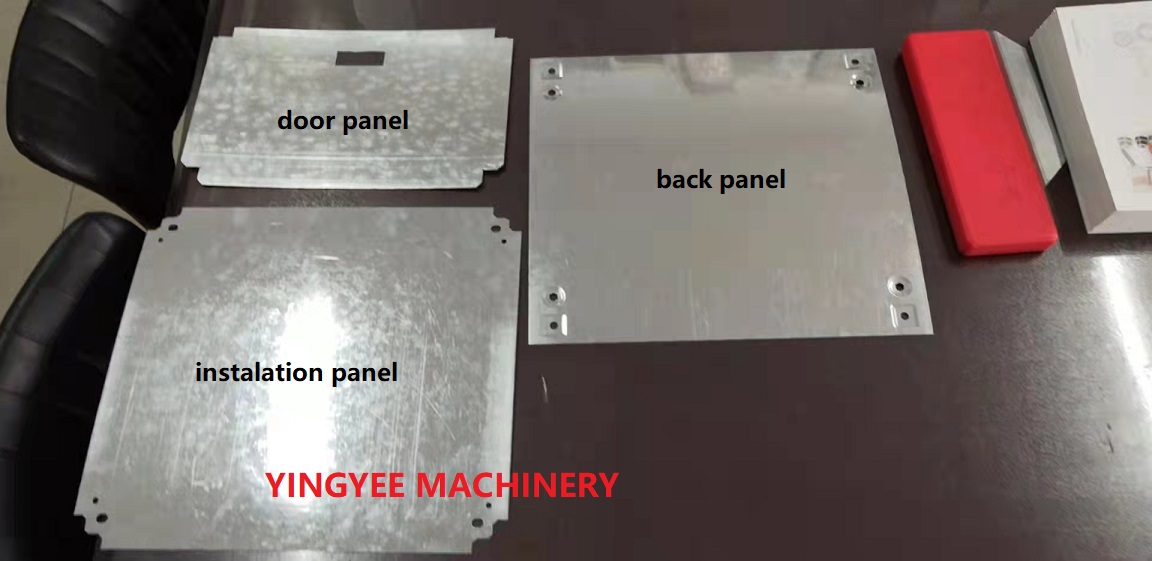

Umshini wamaphaneli wokufaka umnyango ongemuva ohambisana nebhokisi lokuhlangana likagesi

In today's rapidly evolving electrical infrastructure landscape, the demand for standardized yet customizable enclosure solutions has never been higher. YingYee Machinery's Electric Box Roll Forming Machine represents the cutting edge of enclosure manufacturing technology, designed to produce high-precision electrical cabinets and junction boxes with unmatched consistency. This advanced system transforms raw metal coils into perfectly formed enclosures in a continuous, automated process that redefines production efficiency.

The Electric Box Roll Forming Machine excels through its multi-stage forming technology, capable of creating complex box profiles with reinforced corners and precise dimensional tolerances. The intelligent PLC control system allows for seamless adjustment between different box sizes and specifications, while the servo-driven punching unit simultaneously adds knockouts and mounting holes during the forming process. With production speeds reaching up to 25 meters per minute and material thickness handling capabilities from 0.8mm to 3.0mm, this machine establishes new benchmarks for both output volume and product quality in electrical enclosure manufacturing.

The operational excellence of our Electric Box Roll Forming Machine begins with its automated coil feeding system, which ensures continuous material supply without manual intervention. As the metal strip enters the machine, it first passes through a precision leveling unit that eliminates all coil-set memory, guaranteeing perfectly flat starting material. The strip then progresses through a series of computer-optimized forming stations, each progressively shaping the metal into the desired enclosure profile with micron-level accuracy.

Mid-process, the integrated CNC punching system automatically creates all necessary cable entries, mounting holes, and ventilation patterns according to pre-programmed specifications. The final stages feature our patented corner locking technology, which forms interlocking seams for exceptional structural integrity without requiring additional welding. The completed enclosures are then automatically stacked and counted, ready for immediate surface treatment or direct shipment.

The versatility of enclosures produced by our Electric Box Roll Forming Machine continues to grow across multiple sectors. In the energy distribution field, these precision-formed cabinets house critical circuit protection and metering equipment for utility companies. The industrial automation sector relies on them to protect sensitive PLCs and control systems in manufacturing plants.

Telecommunications infrastructure demands these enclosures for 5G network components and fiber optic terminals, while the renewable energy market uses them for solar combiner boxes and wind turbine electrical systems. Even the transportation sector incorporates these enclosures in railway signaling and electric vehicle charging stations.

With increasing global emphasis on electrical safety standards, our machine produces enclosures that consistently meet IP65, NEMA 4, and other international protection ratings, giving manufacturers a competitive edge in regulated markets.