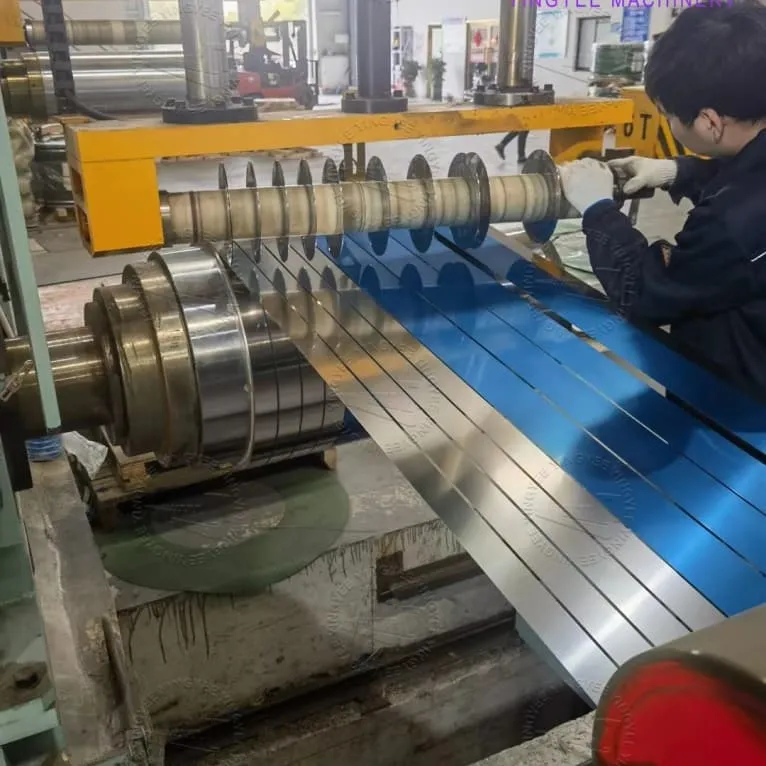

Slitting line, also known as slitting production line, is used to decoiler, slitting, and rewind metal coils into strips of required width. The speed is very fast and the production capacity is high. Compared with the low-speed machine, the output and energy consumption at the same time have obvious advantages. DC main motor, has long life and stable and reliable operation.

It is suitable for processing cold-rolled and hot-rolled carbon steel, silicon steel, stainless steel and various metal materials after surface coating.

High-Precision Slitting Line – Engineered for Efficiency, Built for Reliability

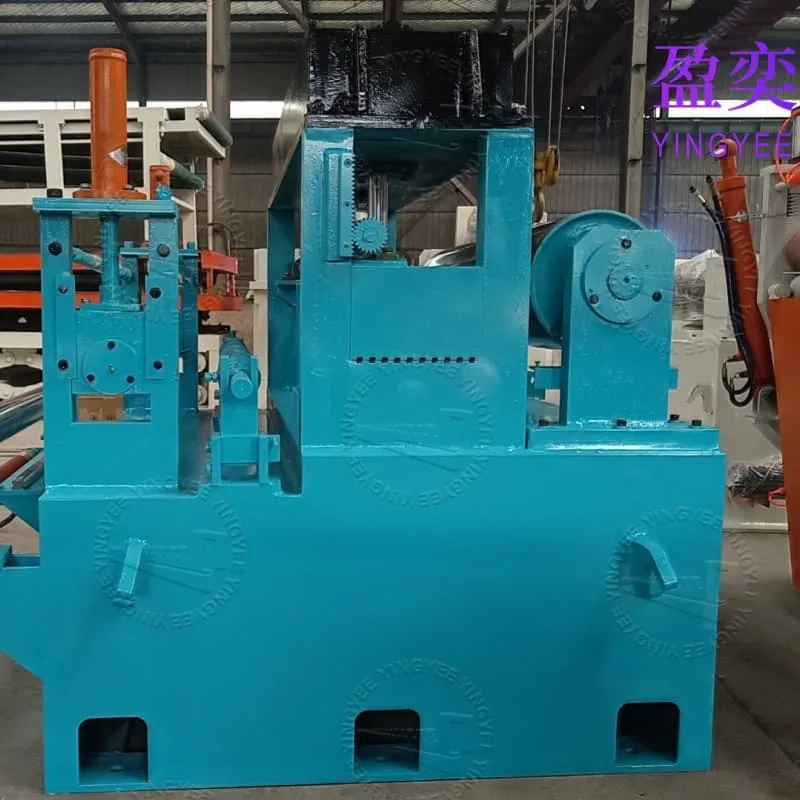

Our Automatic Slitting Line delivers unmatched precision and productivity for metal service centers, steel processors, and manufacturers requiring consistent, high-quality slit coils. Designed to handle a wide range of materials—including galvanized steel, aluzinc, stainless steel, and aluminum—the system transforms master coils into narrow strips with exceptional edge quality, dimensional accuracy, and coil integrity.

Why Customers Choose Our Slitting Line

- ✅ High Precision: Consistent strip dimensions for sensitive downstream processes

- ✅ Fast Changeovers: Reduce setup time by up to 60% with modular cassettes

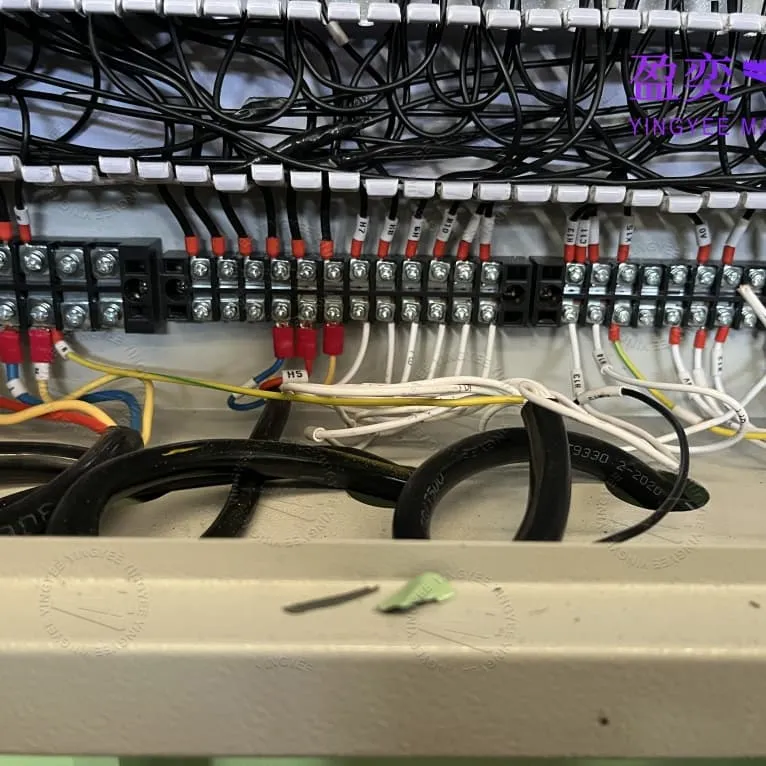

- ✅ Robust Build: Gear-driven slitter head and rigid frame for 24/7 industrial operation

- ✅ Material Flexibility: Process carbon steel, galvanized, stainless, and aluminum on one line

- ✅ Global Compliance: CE certified, with customizable voltage (220V/380V/480V) and multilingual interface

Ideal for producing strips used in roll-formed profiles, electrical enclosures, shelving, automotive parts, and solar mounting systems, our slitting line is a smart investment for businesses aiming to boost capacity, reduce waste, and meet international quality standards.

Custom configurations available—contact us today for a solution tailored to your material specs, output goals, and factory layout.