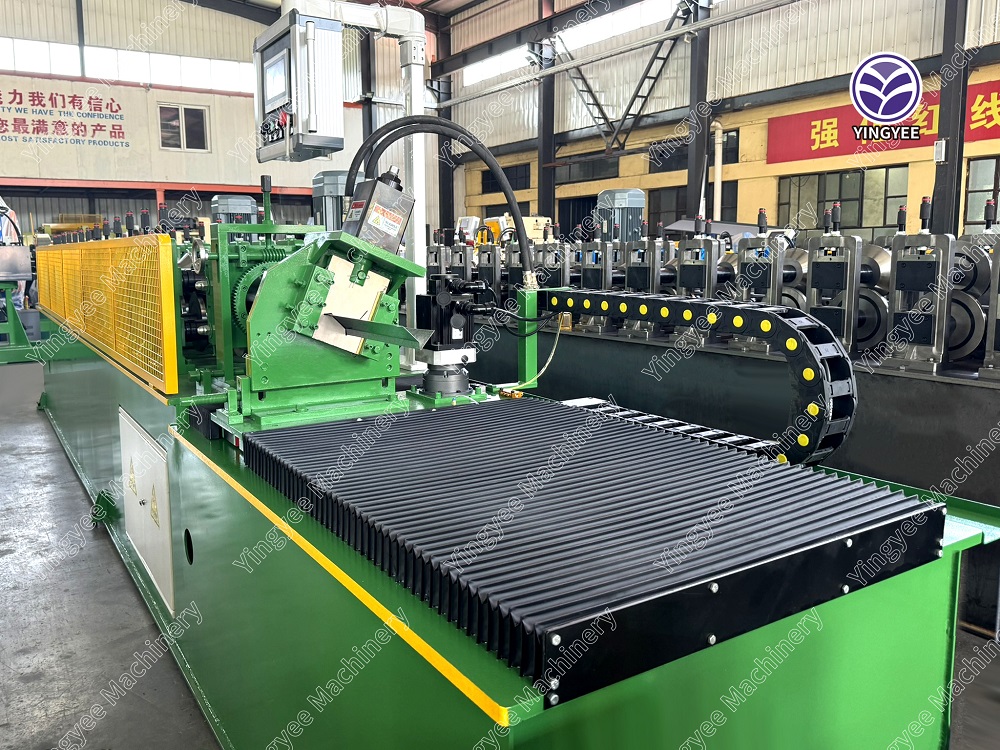

WOrking Process:

Gawo:

Pamanja - coiler x1 gawo l

Zosinthika kulowa zida x1 gawo l

Chachikulu gudubuza kupanga makina ndi chromed mbale x1 kodi

Zopangidwa ndi Hydraulic kudula dongosolo x1 gawo l

Zopangidwa ndi Hydraulic siteshoni x1 gawo l

PLC Kulamulira dongosolo x1 gawo l

Kuthamanga-outtable x1 kodi

Zosintha zaukadaulo

|

Manual Decoiler

|

1: Max m'lifupi zopangira :1300mm2: Mphamvu: 5000kgs3: M'mimba mwake wa coil: 450-600mm |

|

Makina opangira roll

|

1.Matching material:PPGI/GI/Aluminium2.Material thickness:0.2-1mm3.Power:7.5kw4.Forming speed:0-30m/min5.The width of the plates:according to the drawings6.input leveling equipment:adjustable as photos.7.Roll stations:228.Shaft Material and diameter:materialis45#steel ¢80mm, 9.Tolerance:10m±1.5mm 10.Way of drive:chain with the motor

11.Controlling system:PLC

12.Voltage,Frequency,Phase:depend on customer request

13.Material of forming rollers:45#steel heat treatment and chromed 14Materialofcutterblade:Cr12mouldsteelwith quenched treatmentHRC58-62

15. Side plate:steel plate with Chromed.

|

|

Kudula

(chiwongolero cha hydraulic)

|

1. Kudula kusuntha: Makina akulu amangoyima ndikudula. Pambuyo kudula, makina aakulu adzayamba basi.2.Material wa tsamba: Cr12 nkhungu zitsulo ndi quenchedtreatment58-62℃ 3.Utali: Kuyeza kutalika kwa 4.Kulekerera kutalika: 10+/- 1.5mm |

Chithunzi