In the fast-paced world of metal construction, efficiency and precision are non-negotiable. The Automatic C/Z Purlin Roll Forming Machine from YingYee Machinery is engineered to meet the highest industry standards, delivering unmatched speed, accuracy, and durability. Whether you're producing structural components for warehouses, industrial facilities, or commercial buildings, this machine ensures consistent, high-quality purlins with minimal waste.

One of the standout advantages of our machine is its fully automated operation, which drastically reduces labor costs and human error. Equipped with a PLC control system, it allows for quick adjustments to different profiles and thicknesses, ensuring seamless transitions between production runs. The high-strength rollers and precision forming technology guarantee uniform C and Z purlins every time, eliminating defects and rework. Additionally, its energy-efficient design minimizes power consumption, making it a cost-effective solution for large-scale manufacturing.

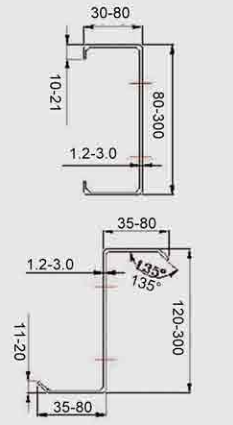

1. Én maskin kan lage alle størrelser av C (bane: 80-300 mm, høyde 35-80) og Z (bane: 120-300 mm, høyde 35-80), som justeres av et helautomatisk PLS-system.

Automatisk CZ purlin rullformingsmaskin, universalkutter kutter alle størrelser, sparer arbeid og materialer

Automatisk cz purlin rulleformingsmaskin med god kvalitet

Maskinen er stor og veier 12 tonn, som er sterk og slitesterk. Maskinen har stabil ytelse og lav feilfrekvens.

Automatisk CZ purlin rullformingsmaskin varmt salg, kan justere størrelsen ved PLC-justering; Den kan også endre C og Z manuelt eller kan med plc-motor. Alle størrelser kan lages i én maskin.

For metal fabricators looking to enhance productivity and expand their product offerings, the Automatic C/Z Purlin Roll Forming Machine is a transformative investment. Unlike traditional manual or semi-automatic machines, our fully automated system ensures high-speed production without compromising quality, making it ideal for high-volume orders.

A key advantage is its versatility—capable of processing various materials, including galvanized steel, aluminum, and pre-painted coils. The machine’s hydraulic cutting system ensures clean, precise cuts with no deformation, while the auto-stacking function streamlines post-production handling. Furthermore, its low maintenance requirements and long-lasting components reduce downtime, maximizing your return on investment.

From roof trusses and wall frames to solar mounting structures, this machine supports a wide range of applications, making it indispensable for modern construction projects.

The Automatic C/Z Purlin Roll Forming Machine is a marvel of modern engineering, combining advanced automation with robust construction to deliver flawless metal profiles. The process begins with coil loading, where the material is fed into the machine automatically, ensuring continuous production. The pre-punching unit (optional) allows for pre-drilled holes, saving time in secondary processing.

As the metal strip moves through the multi-stage forming rollers, it is gradually shaped into precise C or Z purlins with tight tolerances. The integrated high-frequency welding system (for certain models) ensures strong, seamless joints where required. Finally, the hydraulic cutting mechanism trims the purlins to exact lengths, while the automatic stacking system organizes finished products for easy transport.

This seamless operation ensures high output with minimal material waste, making it an ideal choice for manufacturers prioritizing efficiency and sustainability.

The Automatic C/Z Purlin Roll Forming Machine is a cornerstone of modern construction, playing a vital role in a variety of structural applications. Its ability to produce high-strength, lightweight purlins makes it essential for:

Industrial and Commercial Buildings – C and Z purlins are widely used in steel frame constructions, providing support for roofs and walls while reducing overall structural weight.

Warehouses and Storage Facilities – The machine’s high-speed production ensures quick turnaround times for large-scale projects.

Solar Panel Mounting Systems – With the growing demand for renewable energy, our machine produces durable purlins for solar racking structures.

Agricultural Structures – From barns to greenhouses, the corrosion-resistant purlins ensure long-lasting performance in harsh environments.

By integrating this machine into your production line, you can meet diverse customer demands, reduce lead times, and enhance your competitive edge in the global construction market.