Understanding Steel Coil Slitting Lines A Comprehensive Overview

Steel coil slitting lines are essential machinery in the metalworking industry, designed for the precise cutting of large steel coils into narrower strips known as slits. This process plays a pivotal role in various applications across different sectors, including construction, automotive, and manufacturing. In this article, we will delve into the functionality, components, and benefits of steel coil slitting lines.

The Process of Steel Coil Slitting

At its core, steel coil slitting involves feeding a wide coil of steel through a series of rollers and blades to cut it into several narrower widths. The process begins with large steel coils, which are typically unwound and fed into the slitting line. Here’s a step-by-step breakdown of how it works

1. Uncoiling The large master coil, sometimes weighing tons, is uncoiled and straightened to prepare it for slitting. This is crucial because any imperfections in the coil can affect the final product.

2. Slitting As the steel moves through the slitting line, it passes through slitting blades positioned at specific intervals. These blades slice the steel into strips of predetermined widths. The number and width of these strips can be adjusted to meet specific customer requirements.

3. Re-coiling After the steel has been cut, the narrower strips are coiled back into smaller rolls. This re-coiling is essential for handling, storage, and shipping purposes.

4. Inspection and Packaging Finally, the cut coils are inspected for quality and packaged for distribution. Quality control is vital in this process to ensure that the strips meet the required specifications and standards.

Key Components of a Steel Coil Slitting Line

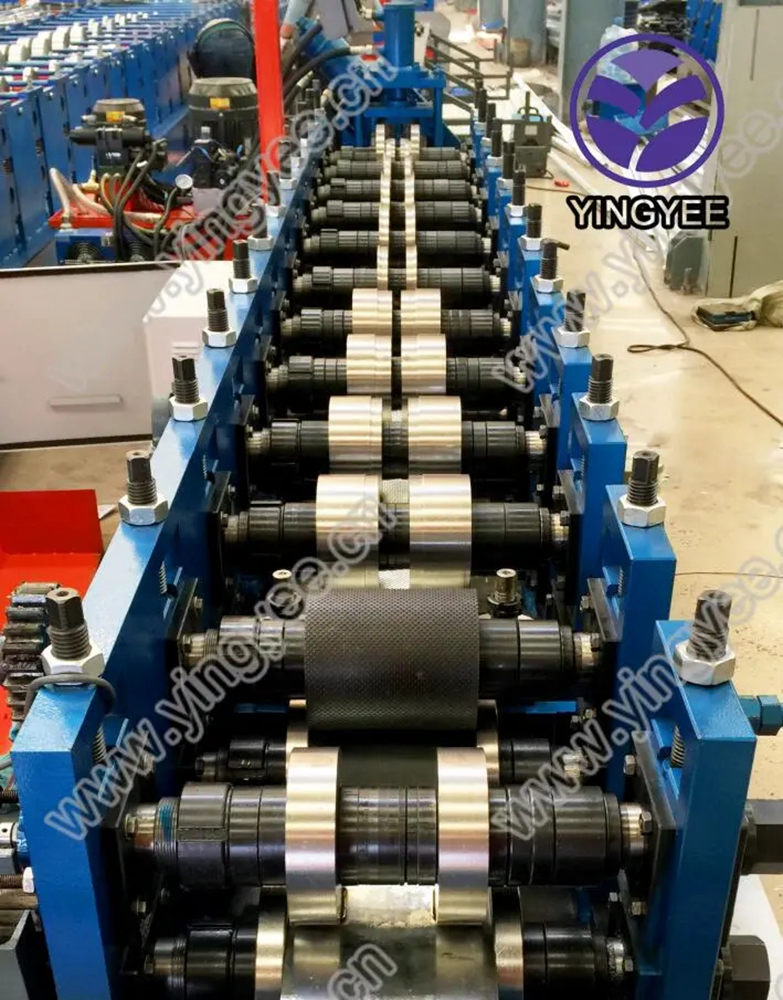

A typical steel coil slitting line comprises several key components that work together to ensure smooth operation

- Uncoiler This device holds the large coil and allows it to unwind smoothly as it enters the slitting line. It is critical for maintaining tension in the coil.

- Straighteners These are used to eliminate any curvature in the steel coil, ensuring that it is flat before slitting. Straightening is crucial for achieving precise cuts.

- Slitting Blades Made from high-strength materials, these blades are designed to withstand the rigors of cutting through thick steel. They can be adjusted according to the desired width of the slits.

- Re-coiler After slitting, the re-coiler is responsible for winding the narrower strips back into coils. It ensures that the final product is compact and manageable.

- Control System Modern slitting lines are equipped with advanced control systems that allow for automation and monitoring. Operators can adjust settings such as cutting speed and blade pressure in real-time to enhance efficiency.

Benefits of Steel Coil Slitting Lines

The use of steel coil slitting lines offers numerous advantages to manufacturers

- Customization Slitting lines can produce strips of various widths and thicknesses, allowing manufacturers to cater to specific needs and preferences. This customization is crucial for industries that require particular dimensions for their products.

- Efficiency Slitting lines improve efficiency by automating the cutting process, reducing manual labor, and minimizing the risk of human error. This leads to significant time and cost savings.

- Quality Control The precision of modern slitting lines ensures high-quality output with minimal waste. Tight tolerances can be maintained, resulting in consistent products that meet industry standards.

- Versatility Slitting lines can handle a variety of materials beyond standard carbon steel, including stainless steel and certain alloys. This versatility makes them valuable assets in a diverse array of manufacturing sectors.

Conclusion

In conclusion, steel coil slitting lines are vital for the efficient processing of steel. By converting large coils into manageable strips, these machines enable the production of customized steel products that meet various industry requirements. With advancements in technology, slitting lines are becoming increasingly efficient and versatile, making them indispensable in the modern metalworking landscape. As industries continue to evolve, the role of slitting lines will be pivotal in shaping the future of steel processing.