Horizontal large span roll forming machines have redefined the landscape of modern manufacturing and construction through their remarkable versatility and efficiency. At the forefront of industrial advancement, these machines cater to a multitude of sectors requiring custom metal forming solutions. Their ability to produce elongated, uniform, and precise profiles is unparalleled, making them indispensable in fabricating expansive structures such as warehouses, bridges, and industrial facilities.

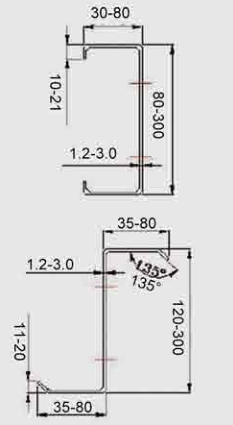

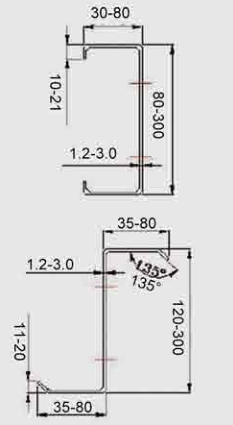

One of the defining characteristics of a horizontal large span roll forming machine is its extensive capacity to produce continuous lengths of metal profiles with high degrees of accuracy. These machines take flat coils of metal and gradually bend them until a desired cross-section profile is achieved. The process’s completeness relies heavily on the machine’s precision engineering, which includes several sets of rollers strategically positioned to execute each bend flawlessly.

The expertise required to operate a horizontal large span roll forming machine is profound. Operators must possess a deep understanding of machine mechanics, material properties, and the specific requirements of each project at hand. Furthermore, they must be adept at troubleshooting and fine-tuning the machines to ensure optimal performance. This level of proficiency ensures that the resulting metal panels meet stringent industry standards and can withstand environmental stresses.

A shining example of the authoritativeness of these machines can be seen in their application within the transport and construction industries. From the robust metal roofing used in large span warehouses to the foundational components in bridge-building, these machines deliver products not just of aesthetic precision but of structural integrity. The cold-rolled profiles they produce are known for their exceptional strength-to-weight ratio, a critical factor in engineering projects where material efficiency and safety are paramount.

What elevates the trustworthiness of horizontal large span roll forming machines is their integration of advanced technologies such as CNC (Computer Numerical Control), which ensures precision, repeatability, and fewer errors in production. The reliability of these machines in producing consistent results reduces waste and increases the efficiency of material utilization, offering substantial economic benefits to companies. This efficiency extends beyond the production line, influencing overall project timelines and costs favorably.

horizontal large span roll forming machine

In terms of real-world experience, numerous case studies highlight the cost-saving advantages and quality improvements brought by adopting horizontal large span roll forming machines. Such machines have been pivotal in projects with tight turnaround times, such as emergency infrastructure developments and swift industrial expansions. Businesses report not only accelerated building speeds but also significant material savings, showcasing the machines’ ability to harmonize swift production with an eco-conscious approach.

The authority and trust instilled in horizontal large span roll forming machines are further solidified through rigorous testing and quality controls. Before a machine leaves the manufacturing floor, it undergoes extensive trials to ensure it adheres to the highest holding standards. Everything from the precision of each roller to the resilience of the machine under prolonged operation is meticulously examined. These steps are vital in cultivating confidence among manufacturers and users, affirming the machine's capability to operate under varied and demanding conditions.

Industry certifications and compliance with international manufacturing standards further underline the trustworthiness and quality of these machines. Manufacturers of horizontal large span roll forming machines are typically ISO-certified, which speaks volumes about their commitment to quality management systems and customer satisfaction.

In sum, horizontal large span roll forming machines epitomize the intersection of innovative design, proficient craftsmanship, and industrial reliability. Their role in shaping contemporary construction and manufacturing methodologies cannot be overstated. For businesses seeking to remain competitive in an ever-evolving market, investing in these advanced machines promises a future of enhanced productivity and sustained growth. As industries continue to demand scalable and precise metal forming solutions, these machines stand ready to meet and exceed expectations, fortifying their place as invaluable assets in industrial production lines worldwide.