The Z shape roll forming purlin machine is an essential piece of equipment in the construction and manufacturing industries, designed to create Z-shaped purlins, which are vital components for various structural applications. This machine enhances productivity and precision in producing purlins, catering to the increasing demand for high-quality building materials.

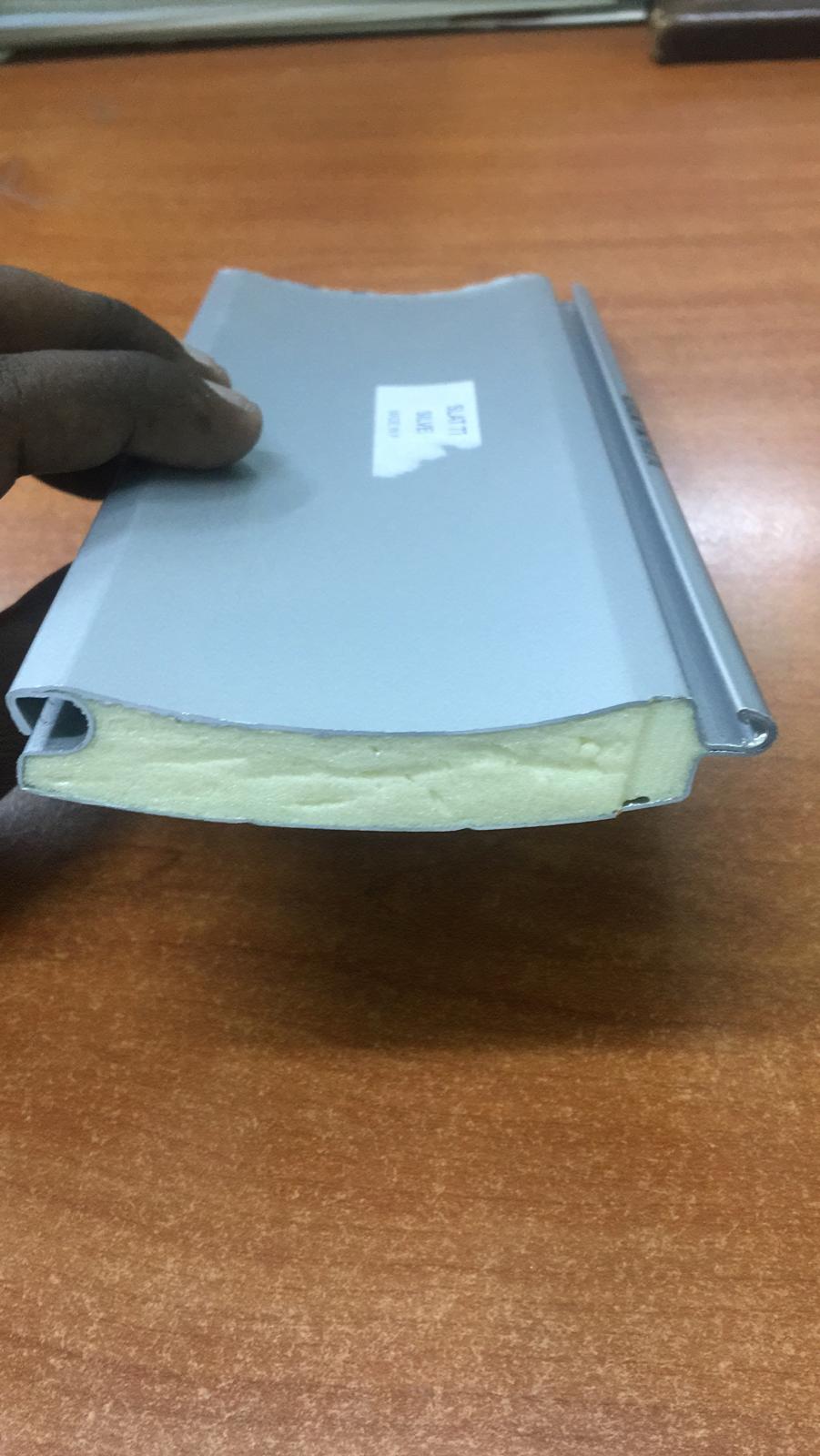

Roll forming is a continuous bending operation where a long strip of metal is fed through consecutive pairs of shaped rollers. The Z shape roll forming purlin machine operates by feeding flat steel or metal sheets into the rollers, which gradually shape the material into the desired Z profile. This method ensures consistent dimensions, strength, and aesthetic appearance, crucial in modern construction practices.

The Z shape roll forming purlin machine is an essential piece of equipment in the construction and manufacturing industries, designed to create Z-shaped purlins, which are vital components for various structural applications

. This machine enhances productivity and precision in producing purlins, catering to the increasing demand for high-quality building materials.Moreover, the Z-shaped purlins produced by this machine are renowned for their structural integrity. The design of the Z shape provides excellent load-bearing capacity, making these purlins ideal for supporting roofs and walls in various building structures. Their lightweight yet durable nature also contributes to easier handling and transportation, further streamlining the construction process.

Automation is another significant feature of modern Z shape roll forming machines. Many models come equipped with advanced control systems, allowing operators to set parameters for dimensions, spacing, and bending angles with high precision. This automation not only minimizes human error but also enhances the overall safety of the operation.

Maintenance and durability of the purlin machine itself are crucial considerations for manufacturers. High-quality materials and robust engineering ensure that these machines can withstand the rigors of continuous operation. Regular maintenance routines, including lubrication and adjustments, can significantly extend the machine's lifespan and efficiency, ensuring that businesses remain competitive in the market.

In conclusion, the Z shape roll forming purlin machine plays a pivotal role in modern construction. Its efficiency, precision, and ability to produce high-quality Z-shaped purlins make it indispensable for builders and manufacturers aiming to enhance structural integrity and streamline production processes. As construction needs evolve, the demand for advanced roll forming technologies will continue to grow, ensuring that machines like the Z shape roll forming purlin machine remain at the forefront of the industry.