The Evolution and Advantages of Z Shape Purlin Roll Forming Machinery

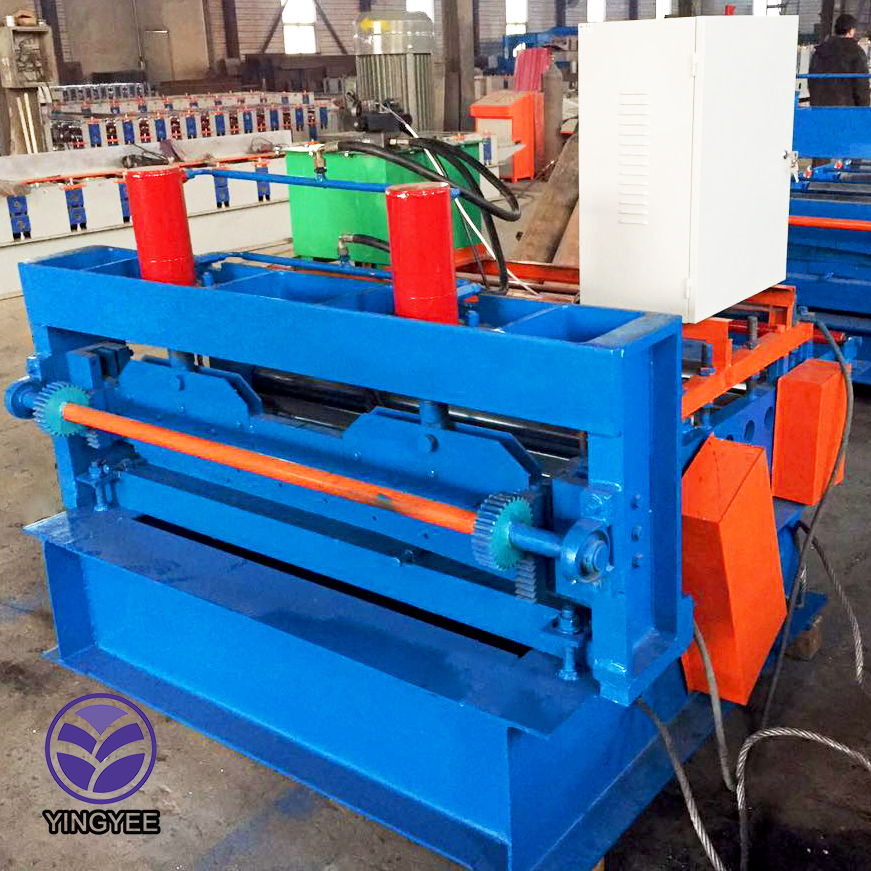

In the realm of modern construction and manufacturing, the efficiency and precision of machine production processes play a crucial role in ensuring the quality and sustainability of materials used. One such innovation that has made significant strides in this domain is the Z shape purlin roll forming machinery. This sophisticated machinery is designed specifically for creating Z-shaped purlins, which are essential components in structural steel framing systems used extensively in commercial and industrial buildings.

What are Z Shape Purlins?

Z shape purlins are horizontal members used in building construction to support roof and wall panels. Their unique shape—resembling the letter Z—allows for efficient load distribution, making them a popular choice among engineers and architects. These purlins are typically made from steel or other high-strength materials, providing durability and resistance to environmental stressors such as wind, snow, and seismic activity.

The Importance of Roll Forming Machinery

Roll forming is a continuous bending operation in which strips of metal are gradually shaped by a series of rollers. Z shape purlin roll forming machinery automates this process, ensuring that the purlins are produced with high precision and a consistent profile. This technology differs from traditional manufacturing methods in several key ways

1. Efficiency The roll forming process is highly efficient, allowing for high-speed production of purlins with minimal waste. The continuous nature of the operation means that long lengths of material can be processed at once, reducing the need for cutting and reworking.

2. Consistency Automated machinery ensures uniformity in product dimensions. This consistency is crucial for maintaining structural integrity and quality in construction applications.

3. Customizability Many modern roll forming machines offer the ability to create purlins in various sizes and specifications based on project requirements. This flexibility allows manufacturers to cater to diverse client needs without compromising on quality.

4. Cost-Effectiveness The use of roll forming machinery can significantly reduce labor costs, as the automation of the process minimizes the need for large teams of workers. Furthermore, the reduction of material waste and the ability to quickly produce large quantities contribute to overall cost savings.

Technological Advances in Z Shape Purlin Roll Forming Machinery

With the ongoing advancements in technology, modern Z shape purlin roll forming machines have evolved to include various features that enhance their capabilities. Many machines are now equipped with computerized control systems that allow for precise adjustments and monitoring of the forming process. This digital oversight not only improves accuracy but also provides users with real-time data that can inform maintenance schedules and production efficiency.

Additionally, the integration of robotics and artificial intelligence in manufacturing processes is set to further transform the roll forming industry. These technologies can automate quality control checks and optimize production schedules, leading to even greater efficiency and reduced downtime.

Conclusion

The significance of Z shape purlin roll forming machinery in the construction and manufacturing industries cannot be overstated. Its combination of efficiency, precision, and cost-effectiveness positions it as a vital tool for producing high-quality structural components. As technology continues to advance, the roll forming process will likely see even more improvements, making it an indispensable part of the modern manufacturing landscape. With the capability to meet the growing demands of the industry while ensuring sustainability, Z shape purlin roll forming machinery is set to play a pivotal role in shaping the future of construction.