Understanding the Z28-300 Thread Rolling Machine Parts

In the world of manufacturing, particularly in the realm of fastener production, thread rolling machines play a critical role. Among the various models available, the Z28-300 thread rolling machine stands out due to its efficiency and effectiveness in producing high-quality threaded fasteners. To appreciate the performance of this machine, it's essential to understand its components and how they work together to achieve optimal results.

Core Components of the Z28-300

1. Rolling Heads The heart of the Z28-300 machine, the rolling heads are responsible for forming threads on the workpiece. These heads typically consist of three rollers that rotate around the workpiece. The design allows for various thread profiles, accommodating different fastener requirements. The precise alignment and controlled pressure of the rollers ensure that threads are rolled accurately and consistently.

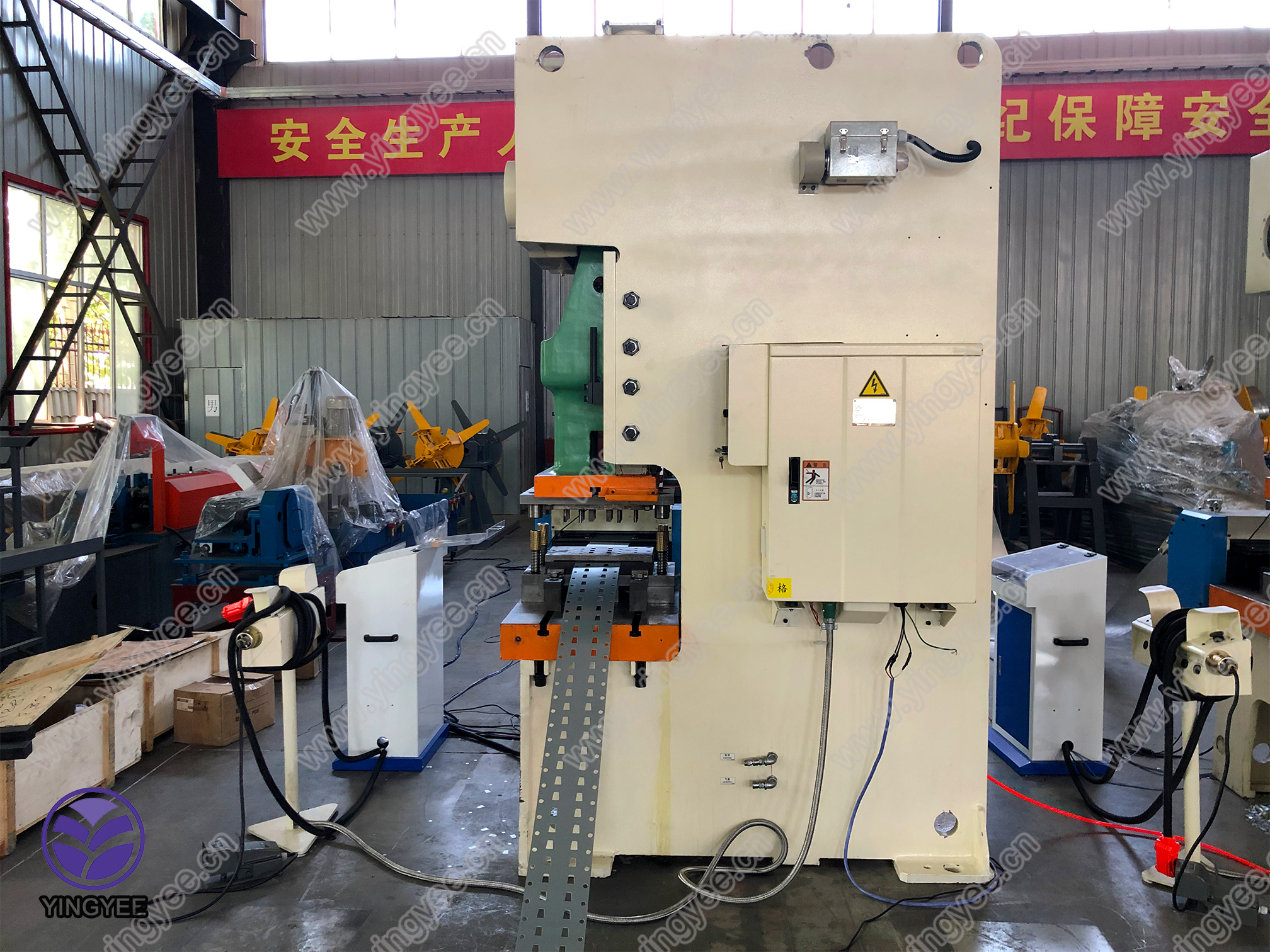

2. Bed and Frame The bed and frame provide the structural integrity of the machine. They are designed to withstand the significant forces exerted during the rolling process. A robust bed helps minimize vibrations, which can lead to inaccuracies in threading. The frame houses various components, keeping the machine stable and durable over time.

3. Power Supply Unit The efficiency of the Z28-300 heavily depends on its power supply unit. This consists of an electric motor that drives the rolling heads. The power supply is designed to deliver consistent torque and speed, which are crucial for achieving high-quality threads without overheating or damaging the material being processed.

4. Workpiece Feed Mechanism This component is responsible for advancing the workpiece into the machine for processing. The feed mechanism must be precise to ensure that the correct amount of material is fed into the rolling heads. Typically, this can be automated, allowing for greater efficiency and reduced labor costs.

5. Control System The control system in the Z28-300 is an advanced feature that allows operators to program the rolling parameters. Modern machines are equipped with PLC (Programmable Logic Controllers) that enable the precise adjustment of speed, pressure, and feed rate. This system enhances repeatability and accuracy, vital for high-volume production where consistency is crucial.

6. Lubrication System To minimize wear and tear on the machine components and reduce friction during the rolling process, a lubrication system is integrated into the Z28-300. Regular lubrication not only increases the lifespan of the machine but also improves the quality of the threads produced. Proper lubrication ensures that the rollers operate smoothly, reducing the chance of thread distortion.

Operational Benefits of the Z28-300

The Z28-300 thread rolling machine is renowned for several operational advantages. Firstly, the cold rolling process it employs maintains the integrity of the metal, resulting in stronger threads compared to traditional cutting methods. As the material is not removed but rather deformed, the grain structure is preserved, enhancing mechanical properties.

Secondly, the Z28-300 is designed for high output. With the ability to produce thousands of threads per hour, it significantly increases production efficiency. Coupled with its automated features, the machine requires minimal human intervention, allowing for greater productivity and cost-effectiveness.

Lastly, the versatility of the Z28-300 cannot be understated. It accommodates various sizes and types of fasteners, making it a valuable asset in diverse manufacturing sectors. Whether it's bolts, screws, or special fasteners, this machine can adapt to meet specific threading requirements.

Conclusion

In summary, the Z28-300 thread rolling machine is a testament to modern engineering in fastener production. Its various components work harmoniously to deliver reliable performance, high efficiency, and quality results. As industries continue to demand stronger and more consistent fastening solutions, machines like the Z28-300 will remain pivotal in meeting these needs. Investing in such advanced machinery not only boosts productivity but also ensures that manufacturers stay competitive in a rapidly evolving market. Understanding the parts and operations of the Z28-300 can lead to better maintenance practices, enhancing its longevity and operational output in the long term.