The Z28-150 Revolutionizing the Thread Rolling Industry

In today's fast-paced manufacturing environment, the quest for efficiency, precision, and consistency is more critical than ever. As industries demand higher standards for their components, the need for advanced machinery has grown exponentially. Among the numerous innovations in this domain, the Z28-150 three-axis thread rolling machine stands out as a leading solution, redefining excellence in thread production.

Understanding the Z28-150

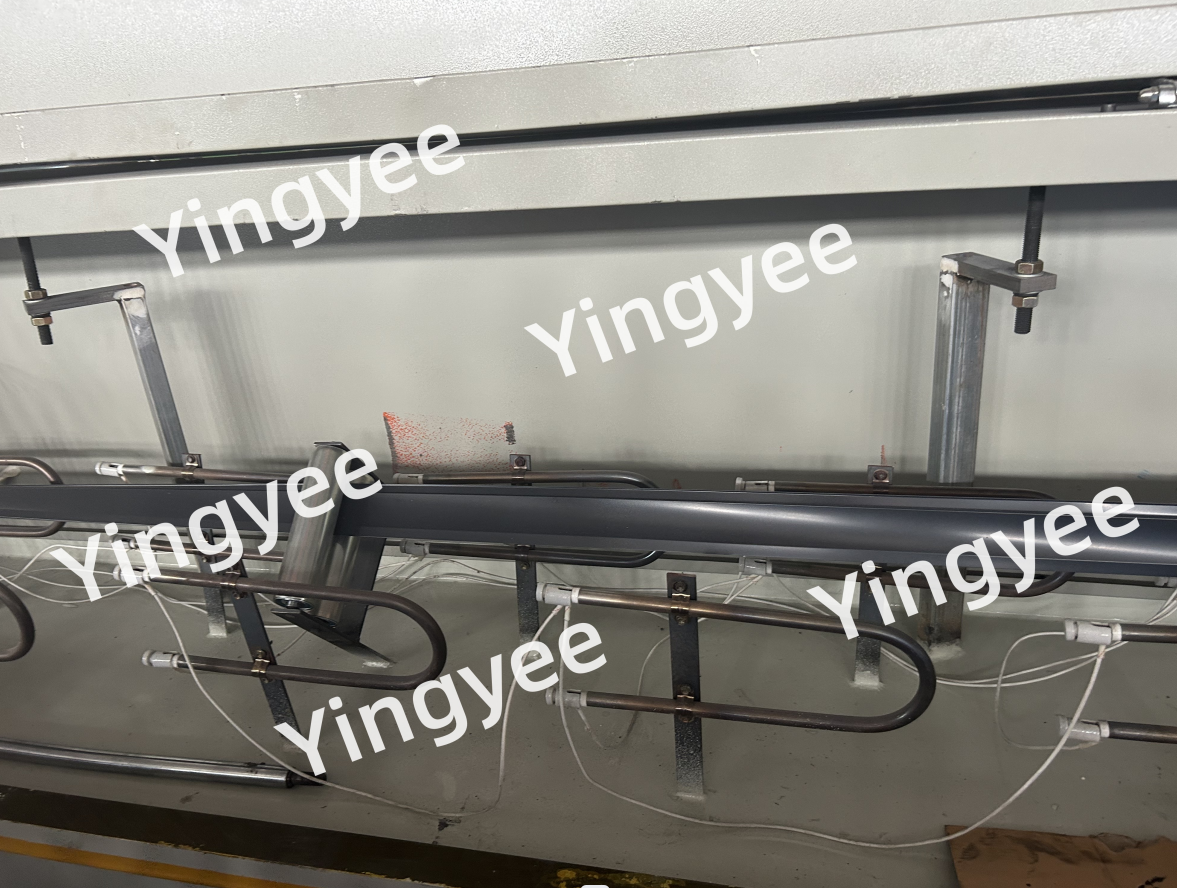

The Z28-150 is a state-of-the-art thread rolling machine designed to produce high-quality threads with remarkable accuracy. Its three-axis configuration allows for complex threading operations that traditional machines struggle to achieve. This versatility makes it ideal for a wide range of applications, from automotive parts to high-precision industrial components.

Key Features and Benefits

1. High Efficiency The Z28-150 is engineered for speed and efficiency. With its advanced motor system, it operates at higher speeds while maintaining consistent quality, significantly reducing production time for manufacturers.

2. Precision Engineering Accuracy is paramount in thread production. The Z28-150 employs high-precision components and cutting-edge technology to ensure that every thread meets stringent dimensional tolerances, minimizing waste and rework costs.

3. User-Friendly Interface The machine is equipped with an intuitive control panel and user-friendly software, allowing operators to set up jobs quickly and easily. This reduces the learning curve for new operators and enhances productivity.

4. Durability and Reliability Constructed from high-quality materials, the Z28-150 is built to withstand the rigors of industrial use. Its robust design minimizes downtime and maintenance costs, ensuring that it remains operational even in the most demanding environments.

5. Versatile Applications The three-axis capability of the Z28-150 allows it to handle various threading tasks, making it suitable for diverse industries. Whether producing standard screws or custom fasteners, this machine can adapt to different requirements with ease.

Industry Impact

The introduction of the Z28-150 thread rolling machine has transformed manufacturing processes across several sectors. By providing a reliable, efficient, and precise solution for thread production, manufacturers can improve their overall output and product quality. This improvement is vital in competitive markets where cost-effectiveness and quality often dictate success.

Moreover, as companies strive to adopt more sustainable practices, the Z28-150 contributes by reducing material waste through its precise threading capabilities. The enhanced efficiency of this machine leads to lower energy consumption and a smaller environmental footprint, aligning with contemporary sustainability goals.

Conclusion

In a world where manufacturing standards continue to rise, the Z28-150 three-axis thread rolling machine emerges as a beacon of innovation. Its combination of speed, precision, and versatility makes it the hottest-selling machine in the industry. Manufacturers looking for a long-term investment that guarantees quality and efficiency will find the Z28-150 to be a game-changer in their production processes.

By adopting this cutting-edge technology, businesses not only enhance their operational capabilities but also position themselves as leaders in their respective fields. The Z28-150 epitomizes the future of thread rolling—efficient, reliable, and indispensable for modern manufacturing. As industries evolve, machines like the Z28-150 will continue to play a pivotal role in shaping the landscape of production and meeting the ever-increasing demands for quality and efficiency.