The Impact of Welded Tube Mills in Modern Manufacturing

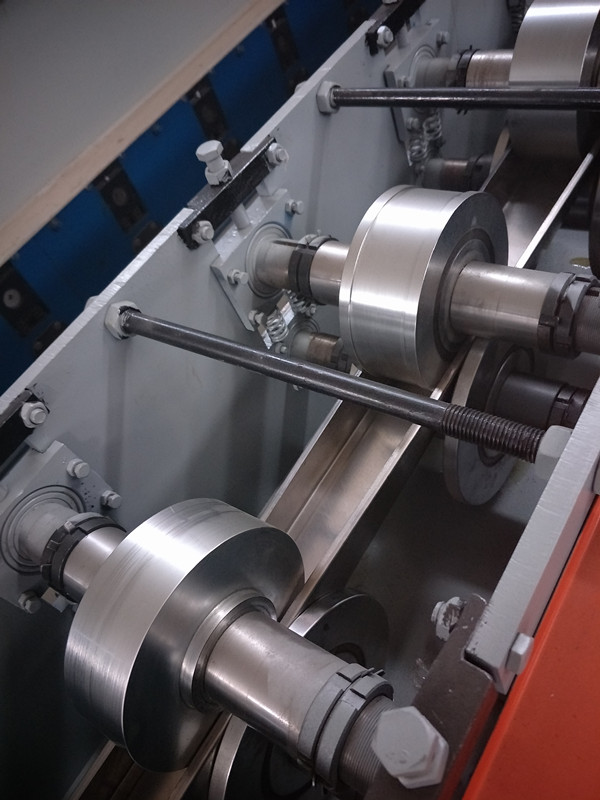

Welded tube mills play a crucial role in modern manufacturing, significantly contributing to various industries, from construction to automotive. These specialized machines are designed to produce high-quality welded tubes with precision and efficiency. The process begins with flat steel coils, which are fed into the mill, where they undergo a series of operations to form tubular profiles.

One of the primary advantages of welded tube mills is their ability to produce tubes in different sizes and thicknesses, catering to diverse applications. The flexibility of these mills allows manufacturers to swiftly adapt to changing market demands. With advancements in technology, modern welded tube mills feature automated systems that enhance production speeds while maintaining quality standards. This automation not only reduces labor costs but also minimizes errors, leading to a more efficient production line.

Moreover, welded tubes are known for their superior mechanical properties compared to seamless tubes. The welding process creates a strong bond that can withstand high pressures, making them ideal for applications in the oil and gas industry, as well as in structural applications where strength is paramount. Additionally, welded tubes offer a cost-effective solution, as they require less material compared to traditional seamless options.

The environmental impact of welded tube mills is also worth noting. As the world shifts towards sustainable manufacturing practices, these mills can utilize recycled materials, reducing waste and energy consumption. Many manufacturers are now focusing on eco-friendly practices, which align with global sustainability goals.

Despite the benefits, the welded tube production process is not without challenges. Ensuring the integrity of the weld is critical, as any defects can lead to significant safety hazards. Therefore, rigorous quality control measures are essential throughout the production process, from the initial material selection to the final inspection of the finished product.

In conclusion, welded tube mills are an integral component of the manufacturing landscape, providing a versatile and efficient means of producing high-quality tubes. With ongoing technological advancements and a focus on sustainability, these mills are poised to meet the needs of an ever-evolving industrial environment. As industries continue to innovate, the role of welded tube mills will undoubtedly expand, further cementing their importance in modern manufacturing.