The Importance of Welded Tube Mill Machines in Modern Manufacturing

Welded tube mill machines play a crucial role in the manufacturing sector, particularly in the production of metal tubes and pipes used across various industries. These machines are designed to create high-quality welded tubes from metal strips, offering an efficient and cost-effective solution for fabricating tubular products. With the rise of industrialization and the ever-increasing demand for metal tubing, the significance of welded tube mill machines has expanded significantly.

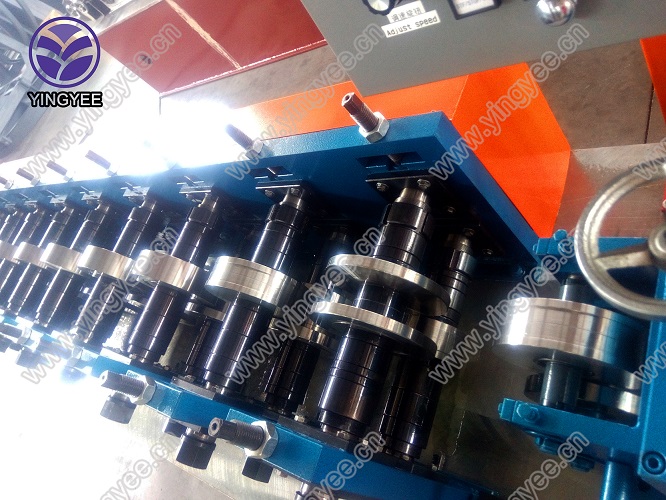

At the heart of a welded tube mill machine is a sophisticated system that combines several process steps, including slitting, forming, welding, and finishing. The process begins with a coil of flat metal strip that is fed into the machine. The strip is then slit to the desired width and continuously formed into a tubular shape using a series of rollers. The edges of the metal strip are brought together and welded, often using high-frequency induction or laser welding methods. This fusion of metal creates a robust bond, ensuring that the finished product is durable and capable of withstanding various pressures and stresses.

One of the key advantages of welded tube mill machines is their efficiency. These machines are capable of producing large quantities of welded tubes in a relatively short amount of time, making them ideal for industries that require high production rates, such as automotive, construction, and oil and gas. Additionally, advancements in technology have led to improved automation and precision in the welding process, ensuring consistent quality in every tube produced. Manufacturers can now achieve tighter tolerances and better surface finishes, which are essential for applications where performance and reliability are critical.

Environmental considerations also play a significant role in modern manufacturing processes. Welded tube mill machines are designed to minimize waste and energy consumption. The closed-loop systems incorporated into these machines enable the recycling of materials, such as scrap metal, reducing the overall environmental impact of production. Furthermore, the efficiency of these machines contributes to a decrease in energy use, aligning with the global push for sustainable manufacturing practices.

In conclusion, welded tube mill machines are integral to the manufacturing landscape. Their ability to produce high-quality, durable welded tubes quickly and efficiently makes them indispensable in various industries. As technology continues to advance, we can expect these machines to become even more efficient, environmentally friendly, and capable of meeting the ever-evolving demands of the market. Investing in state-of-the-art welded tube mill machines not only enhances production capabilities but also supports a commitment to sustainability, ensuring that manufacturers can meet today’s challenges while preparing for the future.