The Importance of W Beam Guard Rails and Roll Forming Machines in Road Safety

When it comes to ensuring the safety of road users, guard rails play a crucial role in minimizing accidents and protecting vehicles from veering off the roadway. One of the most effective designs in this regard is the W beam guard rail, a product engineered for durability and efficiency. The production of these guard rails is made possible through advanced technology involving roll forming machines, which streamline the manufacturing process while ensuring precision and quality.

The Design and Functionality of W Beam Guard Rails

W beam guard rails are characterized by their unique 'W' shape, which provides superior strength compared to flat or less contoured designs. This distinctive shape helps to absorb impact from vehicles, directing the force of a collision in a way that minimizes damage to both the vehicle and the occupants. Additionally, the design allows for effective containment and redirection of errant vehicles, greatly reducing the likelihood of rollovers and severe accidents.

These guard rails are typically made from high-strength steel, treated to resist corrosion and environmental wear. This ensures that they maintain their integrity over many years, even in challenging weather conditions. The installation of W beam guard rails has become a standard practice in many countries, especially along highways and major roadways where traffic flow is significant.

The Role of Roll Forming Machines

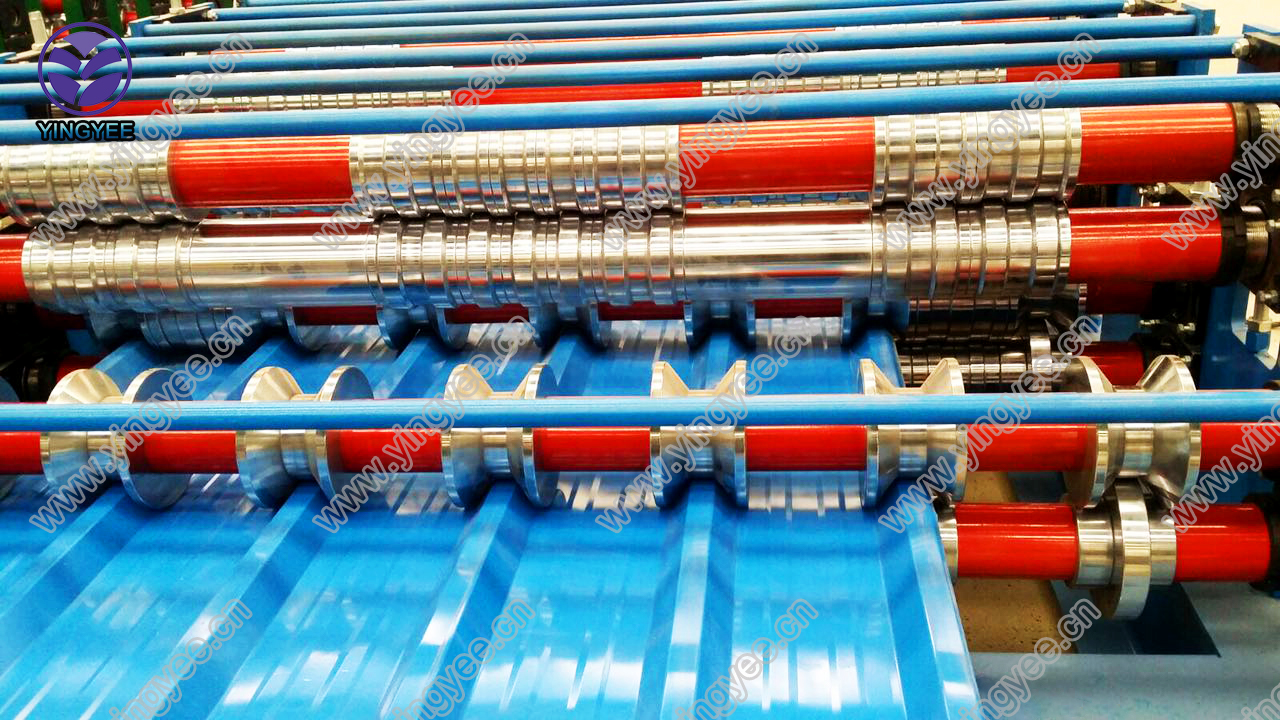

The production of W beam guard rails heavily relies on roll forming machines, which are specifically designed to mold and shape metal sheets into desired profiles continuously. This manufacturing process involves feeding coiled metal into a series of rollers that progressively shape the metal into the W beam profile. The precision of roll forming allows for consistent dimensions and high-quality finish, which are crucial for safety equipment like guard rails.

Roll forming machines offer several advantages in the production of W beam guard rails. First, they provide high efficiency and throughput, as the continuous operation can produce large quantities of guard rails in a relatively short period. Furthermore, the process reduces waste material, as it utilizes the metal more effectively compared to traditional cutting methods.

Quality Control and Innovation

In the modern manufacturing landscape, quality control is of utmost importance, particularly for products associated with safety. Advanced roll forming machines are equipped with sensors and feedback systems that monitor the production process in real-time. This level of oversight ensures that any deviations from specifications are immediately corrected, resulting in a final product that meets stringent safety standards.

Innovation in roll forming technology has also led to enhanced capabilities, such as the ability to produce guard rails with different coatings for added durability and aesthetics. Manufacturers are developing solutions that allow for customized lengths and profiles, catering to the specific needs of various roadways and environments.

Conclusion

W beam guard rails are indispensable in maintaining road safety, and the roll forming machine plays a pivotal role in their production. As infrastructure continues to evolve and the demand for effective safety solutions increases, the integration of advanced manufacturing technology will be essential. Ensuring that road users are protected through the reliable performance of guard rails is a goal that the industry must prioritize, aided by the continued advancements in roll forming processes. By fostering innovation and adhering to strict safety standards, we can help create a safer driving experience for everyone on the road.