The Importance of Cold Bending Machines for W-Beam Guardrails

In the realm of highway safety, W-beam guardrails play a crucial role in protecting both vehicles and pedestrians from potential accidents. These guardrails are designed to absorb impact energy and redirect the vehicles back onto the road, significantly reducing the severity of collisions. The manufacturing process of W-beam guardrails is an intricate one, where precision and durability are paramount. This is where cold bending machines become essential.

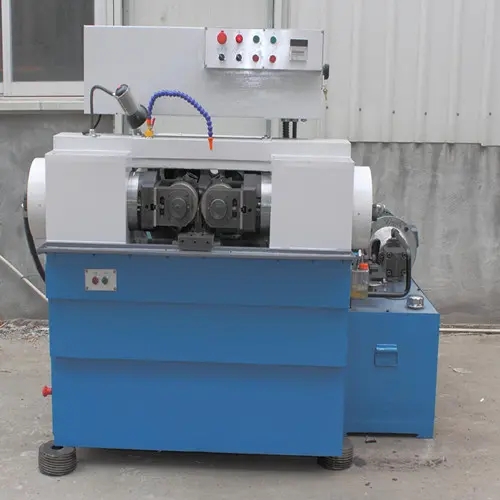

Understanding Cold Bending Machines

Cold bending machines are specialized equipment used to form metal components without the application of heat. This process helps maintain the strength and integrity of the metal, which is crucial for guardrails that need to withstand considerable force during impact. W-beam guardrails are typically made from high-strength steel, which can be easily shaped using cold bending machinery.

The cold bending process involves feeding flat steel strips into the machine. As the steel passes through rollers, it is gradually shaped into a W-beam profile. This method allows for precise angles and dimensions that are critical for the effective performance of guardrails. Additionally, cold bending minimizes the risk of material deformation and ensures a uniform thickness throughout the product.

Advantages of Using Cold Bending for W-Beam Guardrails

1. Strength and Durability One of the primary advantages of cold bending is that it preserves the material's tensile strength. Unlike hot bending, which can alter the microstructure of metals, cold bending maintains the steel's properties, ensuring that the guardrails can withstand harsh environmental conditions and impacts.

2. Cost-Effectiveness The cold bending process is generally more economical than hot bending. It requires less energy and time, leading to reduced manufacturing costs. For companies producing W-beam guardrails at scale, this efficiency translates into significant savings.

3. Precision Manufacturing Cold bending machines are equipped with advanced technology that allows for precise control over the bending process. This precision is vital for meeting regulatory standards for guardrails and ensuring that every product is manufactured to the necessary specifications.

4. Environmentally Friendly The reduced energy consumption associated with cold bending makes it a more environmentally friendly option compared to traditional methods that require heating the metal. As industries increasingly shift toward sustainable practices, the use of cold bending technology aligns well with these goals.

Technological Advancements in Cold Bending Machines

Recent advancements in cold bending machines have greatly enhanced their capabilities. Modern machines come equipped with computer numerical control (CNC) systems that allow for greater automation and accuracy. Operators can input specific measurements, and the machines will automatically adjust to achieve the desired angles and shapes.

Additionally, these machines often incorporate real-time monitoring systems that ensure quality control throughout the bending process. Such innovations not only improve the consistency of the W-beam guardrails produced but also significantly reduce waste material, further enhancing efficiency.

Conclusion

W-beam guardrails are a vital component in maintaining road safety, and the machinery used to produce them plays a pivotal role in their effectiveness. Cold bending machines offer a range of advantages, from enhanced strength and durability to cost savings and precision. As technology continues to evolve, the cold bending process will surely lead to even more innovative solutions in the production of W-beam guardrails.

With the right equipment and expertise, manufacturers can ensure that the guardrails they produce will stand the test of time and serve their purpose in protecting lives. In an era where road safety is paramount, investing in high-quality cold bending machinery is not merely a choice but a necessity for those dedicated to making our roads safer.