Water Gutter Roll Forming Machine An Overview

In modern construction and architectural design, effective water drainage systems are crucial. One essential component of these systems is the water gutter, which helps channel rainwater away from buildings, preventing damage and ensuring structural integrity. To meet the growing demand for high-quality gutters, manufacturers utilize advanced technology, particularly the water gutter roll forming machine.

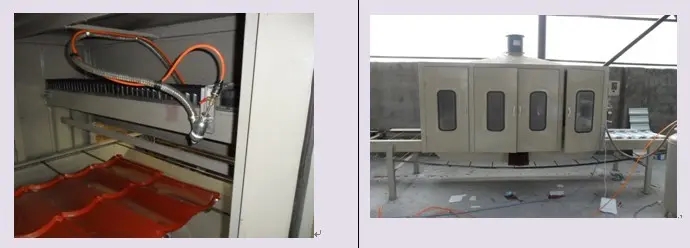

A water gutter roll forming machine is specifically designed to produce continuous lengths of gutter materials from metal sheets, typically galvanized steel, aluminum, or PVC. The machine operates on the principle of cold roll forming, where the metal is shaped into desired profiles through a series of rollers. This process not only enhances the durability of the gutters but also allows for customization in terms of size, shape, and thickness.

One of the significant advantages of employing a water gutter roll forming machine is its efficiency. These machines can produce gutters at a rapid pace, significantly reducing production time compared to traditional methods. Additionally, the precision engineering involved in roll forming ensures that each gutter length meets exact specifications, minimizing waste and ensuring quality consistency.

Furthermore, these machines can be integrated with automated systems for cutting, punching, and bending, allowing manufacturers to streamline their production lines. With features such as programmable logic controllers (PLCs), operators can easily adjust settings to cater to different designs or materials without extensive downtime.

Sustainability is another critical aspect of modern manufacturing, and water gutter roll forming machines contribute positively in this regard. By producing gutters on-demand and minimizing material waste, these machines help manufacturers reduce their environmental footprint. Moreover, metal gutters produced are often recyclable, further promoting eco-friendly practices in the construction industry.

In conclusion, the water gutter roll forming machine is an indispensable tool for manufacturers looking to provide high-quality, durable, and customized gutter solutions. With advancements in technology and automation, these machines represent the future of efficient and sustainable production in the construction sector. As the demand for effective drainage solutions continues to rise, the importance of such machinery will only grow, highlighting the need for innovation in the manufacturing process.