Understanding the Water Gutter Roll Forming Machine

A water gutter roll forming machine has become an essential piece of equipment in the construction and roofing industries. With the increasing demand for efficient and cost-effective solutions for creating gutter systems, these machines have gained popularity for their precision and effectiveness. This article delves into the functionality, advantages, and applications of water gutter roll forming machines.

What is a Water Gutter Roll Forming Machine?

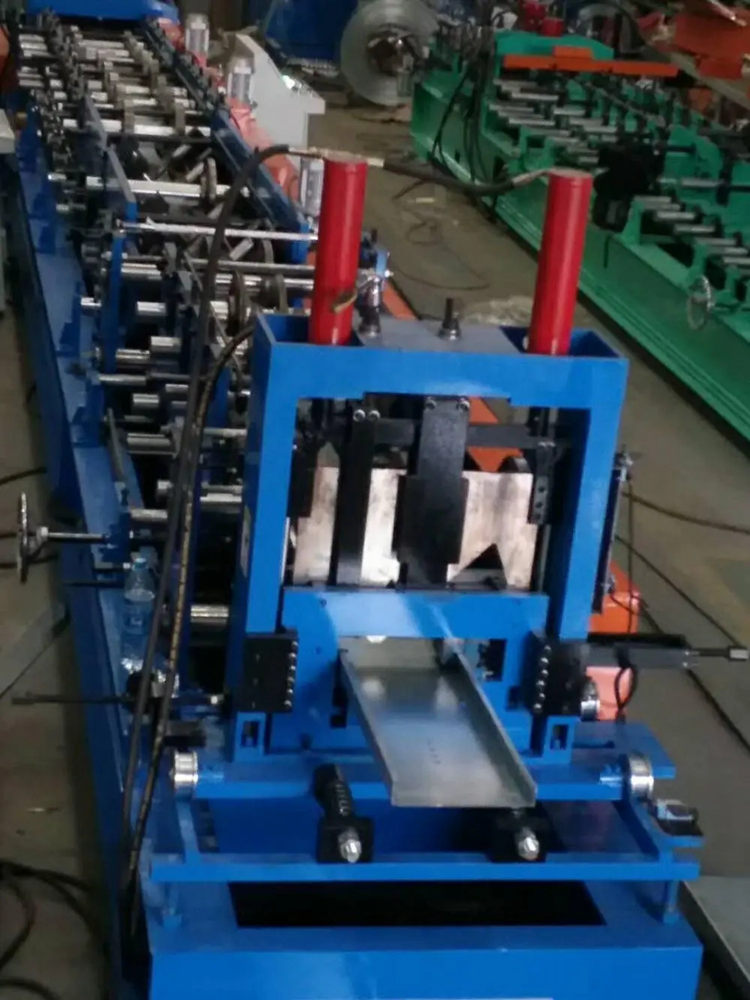

Water gutter roll forming machines are specialized devices designed to produce seamless gutters from metal sheets, typically aluminum or galvanized steel. The roll forming process involves feeding a continuous strip of metal through a series of rollers, which gradually shape the material into the desired profile. This method ensures that the gutters are manufactured with exact dimensions and consistent quality.

The Process of Roll Forming

The roll forming process consists of several stages

1. Material Preparation The process begins with the selection and preparation of the base material. Common materials include aluminum or galvanized steel, known for their durability and resistance to corrosion.

2. Feeding Mechanism The metal sheets are fed into the machine, where they are precisely aligned for uniform shaping.

3. Roll Forming A series of rollers then shapes the metal into the desired gutter profile. Each roller is specifically designed to gradually bend and form the metal strip, ensuring accurate dimensions.

4. Cutting Once the desired length is achieved, a cutting mechanism slices the formed gutter to specifications. This can be automated for precision and efficiency.

5. Finishing Finally, the formed gutters may undergo additional processes such as coating or painting to enhance their appearance and weather resistance.

Advantages of Water Gutter Roll Forming Machines

1. Efficiency The roll forming process allows for rapid production rates. These machines can produce long runs of gutters with minimal downtime, thus increasing productivity.

2. Precision Roll forming machines are designed to produce gutters with exact dimensions and consistent quality. This precision reduces the need for post-production modifications.

3. Cost-Effectiveness While the initial investment in a roll forming machine may be significant, the long-term savings derived from increased efficiency and reduced waste make them economically advantageous.

4. Versatility These machines can be easily adjusted to create different gutter profiles, making them suitable for various projects. This flexibility allows manufacturers to cater to specific client needs.

5. Durability The materials used in the construction of the gutters ensure that they can withstand harsh weather conditions. Roll forming machines can create thick and durable gutters that resist bending and warping.

Applications of Water Gutter Roll Forming Machines

Water gutter roll forming machines are crucial for a variety of applications

1. Residential Construction Homebuilders use these machines to manufacture gutters that fit specific house designs, ensuring proper drainage and complementing the roofline.

2. Commercial Buildings In commercial construction, the demand for standardized and durable gutter systems is high. Roll forming machines can efficiently produce gutters that cater to larger-scale buildings.

3. Renovation Projects For renovation works, custom gutters are often required. A roll forming machine can quickly provide tailored solutions to meet the unique specifications of older buildings.

4. Climate-Specific Solutions In regions prone to heavy rainfall, robust gutter systems are essential. Roll forming machines can produce specially designed gutters capable of handling larger volumes of water.

Conclusion

The water gutter roll forming machine represents a significant advancement in manufacturing technology within the construction sector. By combining efficiency, precision, and versatility, these machines have revolutionized how gutters are produced. As construction continues to innovate, the demand for high-quality roll forming machines is likely to rise, further solidifying their role in building and renovation projects worldwide. Investing in this technology not only enhances productivity but also ensures that builders can meet the escalating demands for effective drainage solutions.