Wall Angle Roll Forming Machine An Overview

In the realm of metal processing and construction, the wall angle roll forming machine plays a crucial role in producing precise and efficient metal profiles. This specialized equipment is designed to form metals into angular shapes that are essential for various applications, particularly in the construction and manufacturing industries. The significance of this technology cannot be overstated, as it facilitates the creation of components that are fundamental to the structural integrity and aesthetic appeal of buildings.

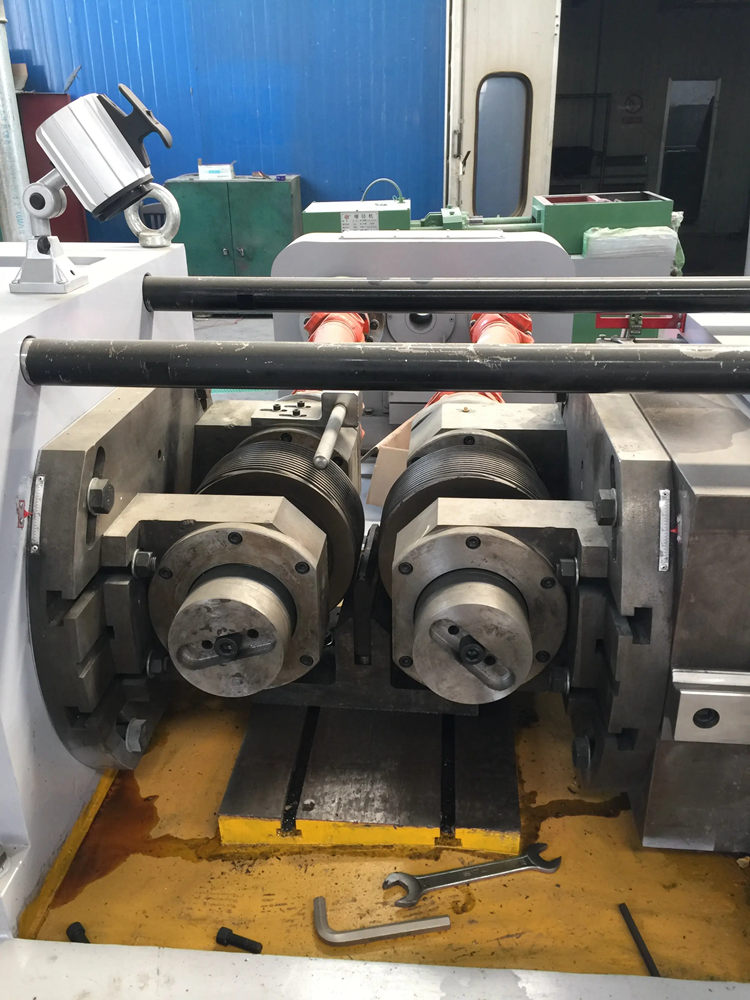

Understanding Roll Forming

Roll forming is a continuous bending operation where a long strip of metal is gradually shaped into desired cross-sectional profiles. The process involves passing the metal through a series of rollers that progressively bend it into the specific shape required. This method is particularly advantageous for producing parts in large quantities with high consistency and minimal waste. Wall angles, which are typically used for framing, support, and other structural elements, are a common application of this technology.

Features of Wall Angle Roll Forming Machines

Wall angle roll forming machines are equipped with several features that enhance their functionality

1. High Precision Advanced technology ensures that the dimensions of the wall angles produced meet strict tolerances. This precision is vital for the components to fit seamlessly into construction applications.

2. Versatility These machines can accommodate various materials, including mild steel, galvanized steel, and aluminum, allowing manufacturers to produce different types of wall angles as needed.

3. Speed and Efficiency The continuous nature of the roll forming process enables high production speeds. This efficiency translates into lower production costs and quicker turnaround times for projects.

4. Customization Many roll forming machines can be tailored to produce specific profiles, catering to individual project requirements. This adaptability is crucial in a market where custom solutions are often demanded.

5. Automation Modern roll forming machines often incorporate automation features that streamline operations, reduce labor costs, and minimize human error. This technology enhances overall productivity.

Applications of Wall Angles

Wall angles are used in a myriad of applications, particularly in the construction sector. Some common uses include

- Framing Wall angles are vital components in constructing internal frames. They provide support for drywall, panels, and other materials. - Ceiling Systems They are commonly used to create grid systems for suspended ceilings, ensuring that the ceiling is both aesthetically pleasing and structurally sound. - Support Structures Wall angles serve as supports for various fixtures, equipment, and other structural elements in commercial and industrial buildings. - Partitions In office spaces and commercial settings, wall angles help create partitions that define workspaces effectively.

Advantages of Using Wall Angle Roll Forming Machines

Investing in a wall angle roll forming machine brings several advantages to manufacturers and contractors

1. Reduced Labor Costs Automation and high production rates mean less labor is required for manufacturing, reducing overall costs. 2. Higher Product Quality The precision of roll forming leads to higher-quality products, which can enhance the reputation of manufacturers in the market. 3. Less Material Waste The efficiency of the roll forming process minimizes scrap, ensuring that materials are used to their full potential. 4. Quick Changeover Many modern machines allow for rapid changeover between different products, making it easy to adapt to changing market demands.

Conclusion

The wall angle roll forming machine is an indispensable tool in modern manufacturing, particularly in the construction industry. Its ability to produce high-quality, precise metal profiles quickly and efficiently makes it a valuable asset for any manufacturer. As the demand for tailored construction solutions continues to rise, the role of technology in streamlining production processes will only become more critical. Investing in advanced roll forming capabilities can provide significant competitive advantages and open new opportunities in an ever-evolving market.