The Benefits of Vertical Large Span Roll Forming Machines

In the modern manufacturing landscape, the efficiency and versatility of production equipment are crucial for businesses looking to maintain a competitive edge. One such innovative solution is the vertical large span roll forming machine, a technology designed to facilitate the production of durable and high-quality metal structures. This article explores the advantages of utilizing vertical large span roll forming machines and their implications for various industries.

What is Roll Forming?

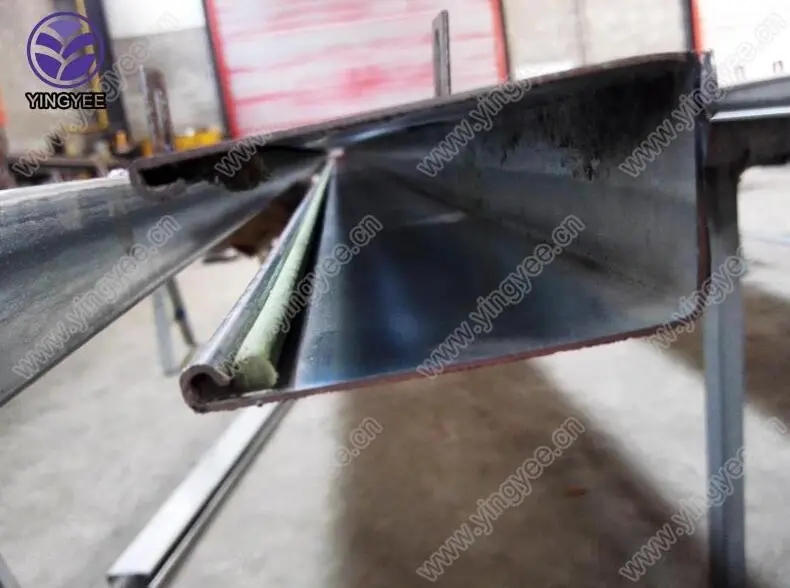

Roll forming is a continuous bending process where a long strip of metal is passed through a series of rollers, which progressively shape the material into the desired cross-sectional profile. The process is highly efficient and can produce complex shapes with precision. Vertical roll forming machines are engineered to handle large spans, making them particularly advantageous for manufacturing components used in construction, transportation, and industrial applications.

Advantages of Vertical Large Span Roll Forming Machines

1. Space Efficiency One of the most significant benefits of vertical large span roll forming machines is their compact design. By orienting the machine vertically, manufacturers can save floor space in their production facilities. This efficiency is vital for businesses that operate in areas where real estate costs are high.

2. Enhanced Production Speed These machines are capable of operating at high speeds without compromising the quality of the output. The continuous nature of the roll forming process allows for quick production cycles, enabling manufacturers to meet high demand while minimizing lead times.

3. Versatility in Design Vertical large span roll forming machines are particularly adept at producing varied profiles and thicknesses. This adaptability makes them suitable for creating products ranging from roofing panels to structural beams, catering to the diverse needs of different sectors.

4. Improved Material Utilization The precision of roll forming minimizes waste, making the process more cost-effective. Manufacturers can utilize materials more efficiently, leading to reduced operational costs and a lower environmental impact.

5. Robust Structural Integrity The products manufactured using roll forming techniques are known for their strength and durability. Vertical large span roll forming machines ensure that each component retains a high structural integrity, making them ideal for critical applications in construction and infrastructure.

Applications in Various Industries

Vertical large span roll forming machines have found applications across a wide array of industries. In construction, they are used to produce columns, beams, and roof trusses that require high strength-to-weight ratios. In the automotive sector, these machines are employed to manufacture body panels and undercarriage components. Additionally, they play a crucial role in creating signage and display systems in the retail industry.

Conclusion

The vertical large span roll forming machine represents a significant advancement in manufacturing technology, offering numerous advantages such as space efficiency, speed, versatility, material utilization, and robust structural integrity. As industries continue to seek innovative solutions to enhance productivity and reduce costs, the adoption of this technology is likely to increase. By investing in vertical large span roll forming machines, manufacturers can position themselves for success in an increasingly competitive marketplace.