The Importance and Functionality of Changeable Z Purlin Roll Forming Machines

In the construction and manufacturing industries, the need for durable and lightweight structural components has led to the increased use of purlins. Among the various types of purlins used, Z purlins stand out due to their strength and versatility. With the ever-evolving demands of the industry, the advent of changeable Z purlin roll forming machines has revolutionized how manufacturers produce these essential components.

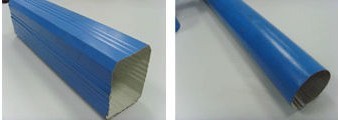

Understanding Z Purlins

Z purlins are horizontal structural members used primarily in building frameworks, particularly in steel structures. They provide support for roofs and walls and can be easily assembled into various shapes and sizes. Their unique design allows for efficient load distribution and increased structural integrity. Traditionally, fabricating Z purlins required extensive manual labor and multiple processes, leading to inefficiencies and higher production costs.

What is a Changeable Z Purlin Roll Forming Machine?

A changeable Z purlin roll forming machine is an advanced manufacturing system designed for the production of Z purlins with adjustable specifications. Unlike fixed roll forming machines that can only produce a specific design or size, changeable models offer flexibility, allowing manufacturers to modify dimensions and configurations quickly. This adaptability caters to diverse customer needs and helps reduce idle time during production.

Key Features of Changeable Z Purlin Roll Forming Machines

1. Adjustable Roll Sets Changeable Z purlin machines come equipped with adjustable roll sets, allowing operators to easily alter the size and shape of the purlins being produced. This feature minimizes the need for multiple machines and tools, streamlining the manufacturing process.

2. Automatic Control System Most modern roll forming machines incorporate advanced automation technologies, enabling precise control over the forming process. With an automated system, manufacturers can achieve consistent quality in purlin production, reduce human error, and enhance overall efficiency.

3. User-Friendly Interface Operators benefit from an intuitive and user-friendly interface, making it easier to switch between different purlin styles and sizes. This reduces training time for new personnel and increases overall productivity.

4. High Production Speed These machines are designed to operate at high speeds without compromising quality. This increased production capability allows manufacturers to meet growing market demands and tight deadlines.

5. Durability and Reliability Changeable Z purlin roll forming machines are built with high-quality materials and components, ensuring that they can withstand continuous operation while maintaining performance integrity.

Benefits to the Industry

The introduction of changeable Z purlin roll forming machines has had significant implications for the construction and manufacturing sectors. Manufacturers can now respond swiftly to changing customer specifications, leading to greater flexibility in production. Additionally, the reduction in setup time translates to lower operational costs, which can be passed on to customers, providing competitive pricing in the marketplace.

Moreover, these machines contribute to inventory management by enabling manufacturers to produce smaller, bespoke batches of Z purlins on demand. This capability is particularly valuable in an industry moving towards custom solutions rather than mass production.

Conclusion

Changeable Z purlin roll forming machines represent a significant advancement in manufacturing technology, addressing the needs of an industry that constantly requires adaptability and efficiency. By simplifying the production process, enhancing product quality, and reducing costs, these machines not only improve the manufacturing workflow but also support the sustainable growth of the construction sector. As building designs continue to evolve and become more complex, the role of efficient and flexible machinery like the changeable Z purlin roll forming machine will undoubtedly become even more critical.