Quick Changeable C/Z Purlin Roll Forming Machine A Game-Changer in Construction

In the modern construction industry, efficiency, versatility, and cost-effectiveness are paramount. One of the innovations that have significantly impacted these aspects is the Quick Changeable C/Z Purlin Roll Forming Machine. This advanced machinery has revolutionized the way purlins, which serve as crucial structural components in various buildings, are manufactured.

Understanding the C/Z Purlin

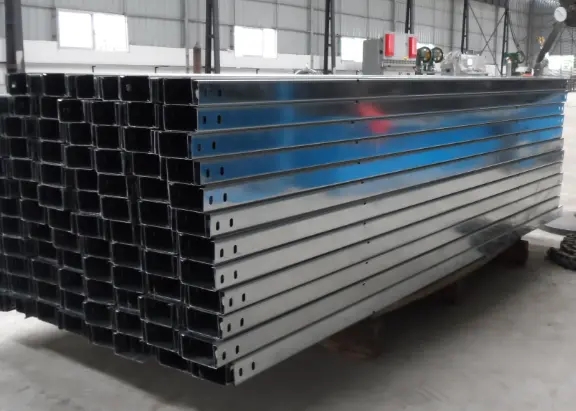

C/Z purlins are horizontal structural members that support the roof and walls of buildings, providing stability and strength. The 'C' and 'Z' designations refer to the cross-sectional shapes of the purlins. While C purlins are primarily used in supporting horizontal loads, Z purlins are often utilized for their ability to provide superior strength in vertical applications. Both types are essential in creating robust frameworks for warehouses, factories, and commercial buildings.

The Role of Roll Forming Machines

Roll forming machines play a pivotal role in the production of C/Z purlins

. These machines use a continuous bending operation to shape strip metal into the desired cross-section, allowing for high-volume production with minimal waste. Conventional roll forming machines often produce one type of purlin at a time, but the introduction of quick changeable technologies has transformed this process.Advantages of Quick Changeable Technology

1. Efficiency Quick changeable roll forming machines can transition from producing C purlins to Z purlins within a matter of minutes. This reduces downtime and increases productivity, as manufacturers no longer need to invest large amounts of time and resources to reconfigure machines.

2. Flexibility With consumer demands shifting towards customized solutions, these machines can effortlessly adapt to produce various sizes and thicknesses of purlins. This flexibility is crucial for contractors who require specific designs for different projects.

3. Cost-Effective Production By minimizing downtime and reducing the need for multiple machines, manufacturers can significantly decrease operational costs. Furthermore, the ability to produce purlins on demand allows for better inventory management and reduced storage costs.

4. Quality Control Advanced quick changeable roll forming machines are equipped with state-of-the-art technology that ensures consistent quality across production runs. Features such as automatic adjustments for thickness and length ensure that every purlin meets rigorous industry standards.

5. Sustainability With an emphasis on reducing waste, these machines are designed to optimize material usage. By efficiently utilizing raw materials, manufacturers can contribute to more sustainable building practices.

Conclusion

The Quick Changeable C/Z Purlin Roll Forming Machine stands out as a pivotal development within the construction industry. Its ability to rapidly shift between production types delivers unprecedented efficiencies and cost savings, meeting the sector’s growing demands for speed and customization. As the industry continues to evolve, investment in such innovative technologies will undoubtedly play a vital role in staying competitive.

In summary, as construction projects become increasingly complex and time-sensitive, the quick changeable C/Z purlin roll forming machine offers a reliable solution for manufacturers looking to enhance productivity and flexibility. Embracing this technology is not just a strategic advantage; it is essential for meeting the future challenges of the construction industry.