U-Shape Frame Forming Machine An Overview

In the modern manufacturing landscape, the U-Shape frame forming machine plays a crucial role in various industries. These machines are specifically designed to produce U-shaped frames used in construction, automotive, and other sectors requiring sturdy structural components. The versatility and efficiency of these machines make them invaluable in facilitating rapid production and ensuring precise dimensions.

What is a U-Shape Frame Forming Machine?

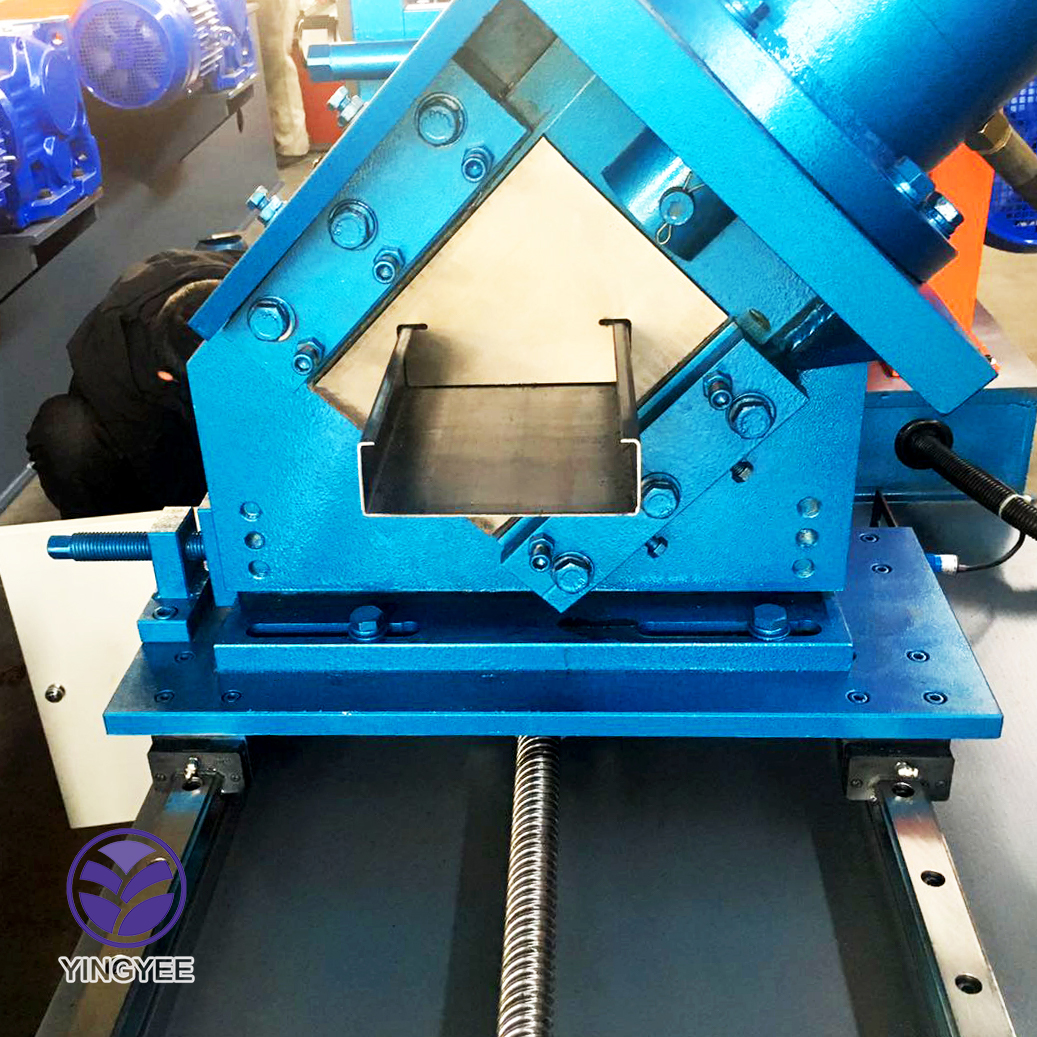

A U-Shape frame forming machine is a specialized piece of equipment that fabricates U-shaped metal frames from flat metal sheets or coils. The process typically involves several stages, including feeding, shearing, bending, and welding. The machine transforms flat materials into three-dimensional shapes through a series of mechanical operations, which may include roll forming, bending, and cutting.

The roll forming process is particularly significant in this context. It involves feeding the metal into a series of rollers, each gradually bending the material until the desired U-shape is achieved. The precision of this process is vital, as even minor deviations can result in structural weaknesses, affecting the integrity of the final product.

Key Features

1. High Precision U-Shape frame forming machines are designed with advanced technology that enables high precision in forming. Computer Numerical Control (CNC) systems are often integrated into these machines, allowing for accurate programming and automation of the forming process.

2. Versatility These machines can work with various materials such as steel, aluminum, and other alloys. This adaptability allows manufacturers to produce a wide range of U-frame products for different applications.

3. Production Efficiency The automation capabilities of U-Shape frame forming machines significantly enhance production speed. Continuous operation and minimal manual intervention lead to increased output, making them cost-effective for high-volume manufacturing.

4. Durability The structural integrity of the U-shaped frames produced by these machines is paramount. The equipment is constructed using high-quality materials, ensuring durability and long-term service life.

5. User-Friendly Interface Modern machines are equipped with intuitive control panels that allow operators to set parameters easily, monitor the forming process, and adjust settings as necessary, thus reducing the learning curve and increasing productivity.

Applications

U-shaped frames have a multitude of applications across various industries

- Construction In the construction sector, U-shaped frames are often used as supports for walls, roofs, and other structural elements. They provide strength and stability, making them essential for building integrity.

- Automotive The automotive industry utilizes U-shaped frames in vehicle manufacturing, particularly for chassis and body structures. Their lightweight yet robust nature contributes to fuel efficiency without compromising safety.

- Furniture U-shaped frames are also found in the production of furniture. They provide a solid base for tables, chairs, and other pieces, ensuring durability and aesthetic appeal.

- Industrial Equipment Many types of machinery and industrial equipment utilize U-shaped frames for support structures, enhancing stability and performance during operation.

Future Trends

As technology continues to evolve, the future of U-Shape frame forming machines is promising. Innovations such as artificial intelligence and Internet of Things (IoT) integration are set to enhance machine performance further, allowing for real-time monitoring and predictive maintenance. Additionally, advancements in materials science may lead to the development of new composite materials, expanding the scope and application of these machines.

The growing emphasis on sustainability in manufacturing processes will also influence the design and operation of U-Shape frame forming machines. Manufacturers are increasingly adopting practices that minimize waste and energy consumption, aligning with global sustainability goals.

Conclusion

In summary, the U-Shape frame forming machine is an integral part of modern manufacturing processes. Its high precision, versatility, and efficiency make it essential for producing U-shaped frames used in a variety of applications. As technology advances and industries evolve, these machines will undoubtedly adapt, continuing to play a key role in shaping the future of manufacturing. With a commitment to quality and innovation, manufacturers can enhance productivity and meet the demands of an ever-changing market landscape.