U Purlin Roll Forming Machine A Comprehensive Overview

In the realm of modern construction and metal fabrication, efficiency and precision are paramount. One of the key machines facilitating these demands is the U Purlin Roll Forming Machine. This innovative piece of equipment is essential for manufacturing U-shaped purlins, which are critical components in various structural applications, including roofs, walls, and frames.

What is a U Purlin?

Before delving into the machine itself, it's important to understand what U purlins are. A purlin is a horizontal structural member that supports loads and is usually made of steel. The U shape refers to its cross-sectional design, which provides excellent strength and stability while minimizing weight. U purlins are commonly used in the construction of warehouses, factories, and agricultural buildings, due to their versatility and efficiency.

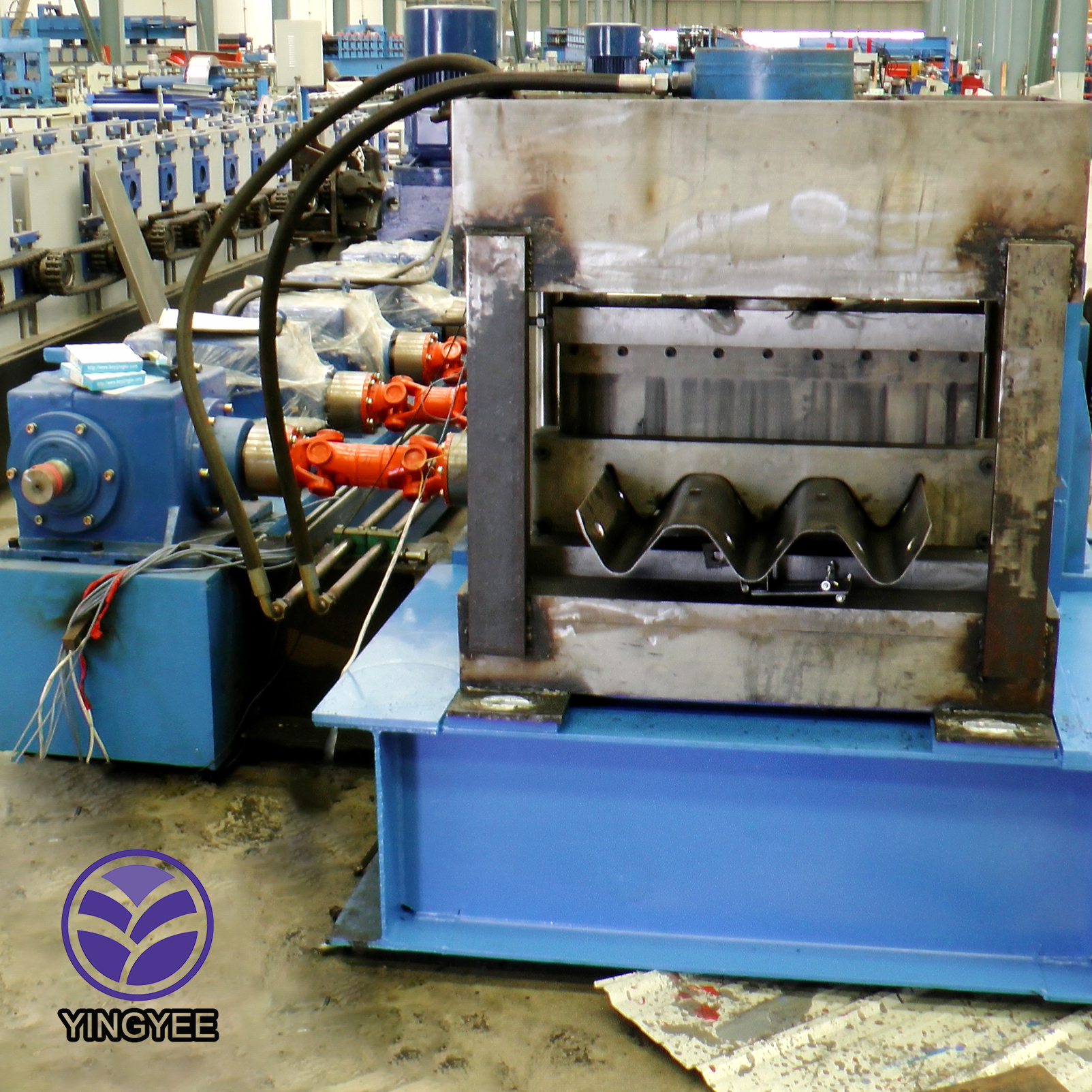

The Functionality of the U Purlin Roll Forming Machine

The U Purlin Roll Forming Machine is designed to transform raw metal coils into high-quality U purlins through a continuous process. This machine operates by feeding metal sheets into a series of rollers that gradually shape the material into the desired U-profile. The process typically includes several key stages

1. Decoiling The machine begins with a decoiler that unwinds the metal coil before feeding it into the forming section. 2. Roll Forming As the metal moves through the roll stations, consecutive rollers bend it into the U shape. This stage requires precision engineering to ensure the final product meets specified dimensions.

3. Cutting Once the desired length is achieved, the machine automatically cuts the purlin. Advanced models can include length adjustments based on the user's requirements.

4. Packaging Finally, the finished products are collected and prepared for shipping, ensuring that they are ready for use in construction projects.

Advantages of Using U Purlin Roll Forming Machines

Investing in a U Purlin Roll Forming Machine comes with numerous advantages. Firstly, it offers high production efficiency, allowing manufacturers to produce large quantities of purlins quickly and reliably. The automation of the process minimizes manual labor, reducing the risk of errors and improving workplace safety.

Additionally, the precision of the roll forming process ensures that each purlin meets specified tolerances, leading to superior quality and performance in structural applications. With the ability to produce various sizes and dimensions, these machines provide flexibility to cater to diverse construction needs.

Conclusion

In conclusion, the U Purlin Roll Forming Machine plays a critical role in modern construction and metalworking industries. Its ability to efficiently produce high-quality U purlins makes it an indispensable tool for manufacturers and builders alike. As construction demands evolve and the need for sustainable solutions increases, machines like the U Purlin Roll Forming Machine will continue to be at the forefront of industry innovation, contributing to more robust and efficient building practices. Whether for large-scale infrastructure projects or smaller constructions, the importance of this machine cannot be overlooked as it helps shape the framework of our built environment.