Standing seam roofing systems are among the most durable and aesthetically appealing options available for both residential and commercial buildings. The demand for high-quality standing seam roofing is growing as more people recognize its advantages, including water resistance, energy efficiency, and long-term durability. To meet this demand, investing in the right equipment is essential. A standing seam machine for sale, a standing seam metal machine, a standing seam roofing machine, and a standing seam roof machine are the perfect tools for producing these highly sought-after roofing panels. Let’s take a closer look at how these machines can boost your business.

Why You Should Consider a Standing Seam Machine for Sale

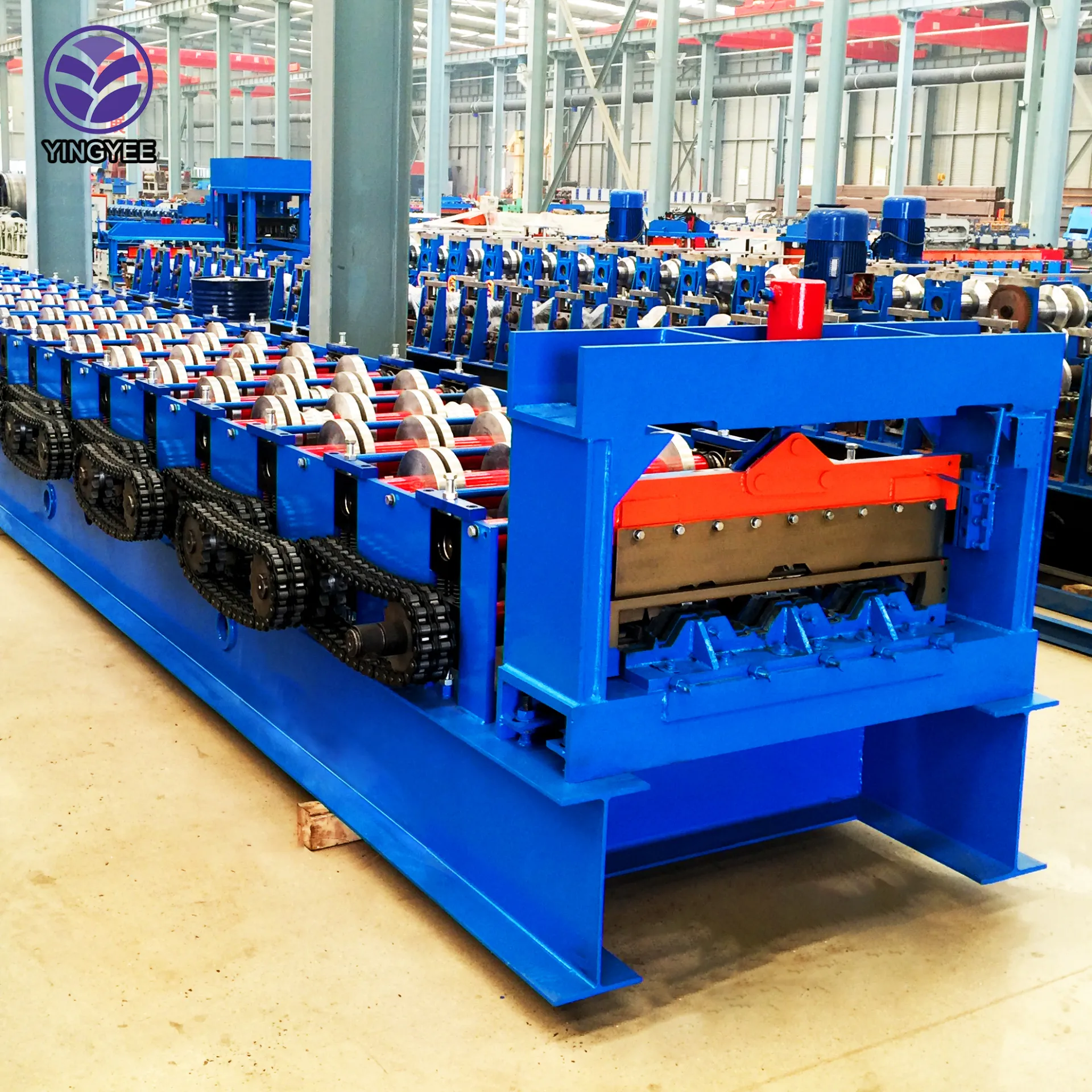

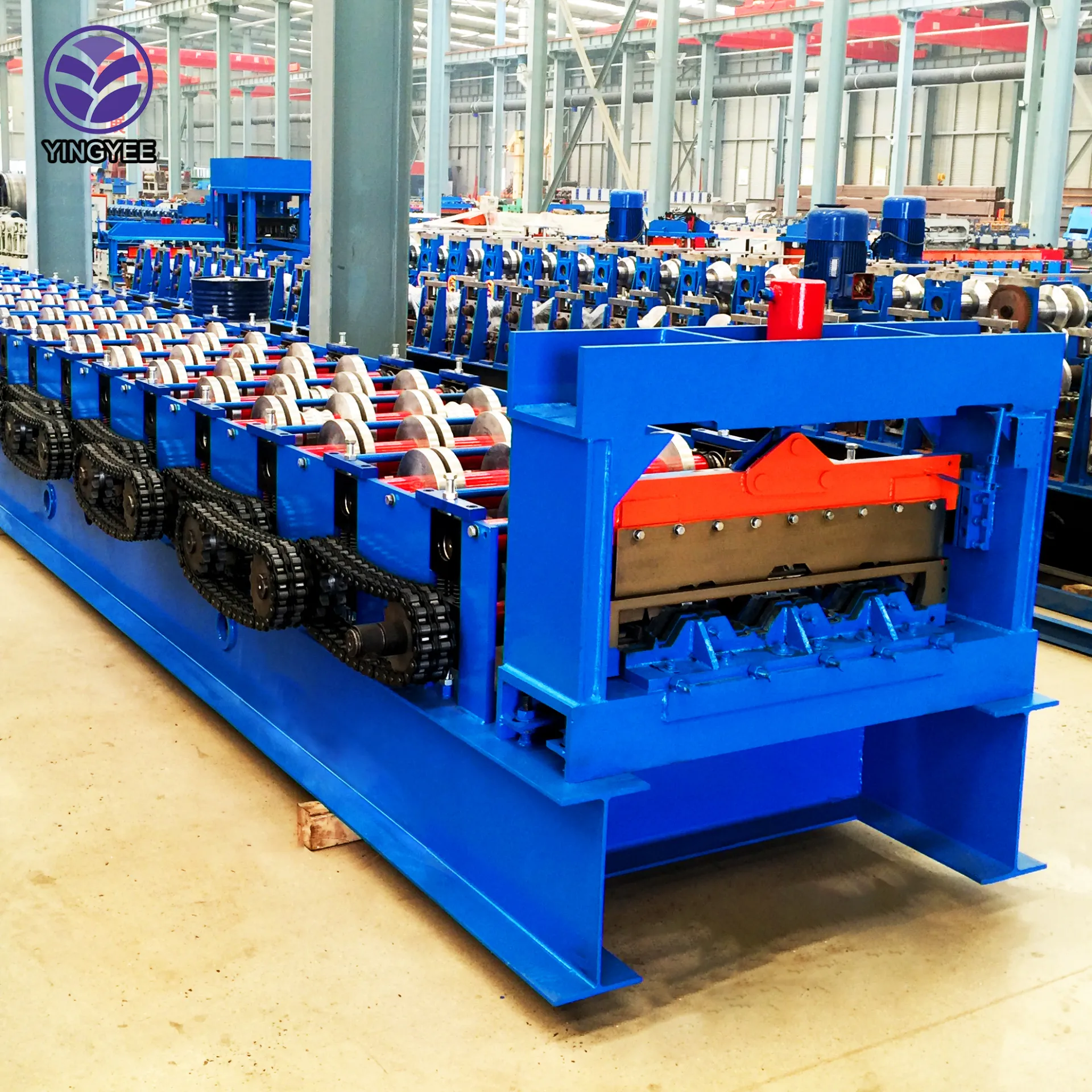

A standing seam machine for sale is an essential piece of equipment for anyone looking to produce top-tier standing seam panels efficiently. When you purchase a standing seam machine for sale, you gain access to a powerful tool capable of creating strong, long-lasting roofing materials for various construction projects. The machine can form seamless, watertight panels that are perfect for both residential and commercial roofing.

By investing in a standing seam machine for sale, you can increase your production capacity and lower manufacturing costs while improving the overall quality of your roofing materials. These machines provide exceptional precision and can handle a wide range of metal materials, including steel and aluminum. The ease of operation and high speed of production make a standing seam machine for sale a cost-effective investment for roofing businesses aiming to scale operations or improve their service offerings.

The Benefits of a Standing Seam Metal Machine

The standing seam metal machine is designed to create metal panels with a raised seam, which is ideal for roofing applications. The standing seam metal machine ensures that your panels are strong, durable, and highly resistant to harsh weather conditions. This is particularly beneficial for roofing systems that require a high level of water resistance and energy efficiency, as the seams are designed to prevent water infiltration.

A standing seam metal machine is versatile and allows for customization of panel sizes and profiles. This flexibility makes it possible for roofing companies to meet the specific requirements of any project. Additionally, the machine is capable of producing large volumes of standing seam panels with minimal waste, making it an essential tool for high-demand roofing projects. Investing in a standing seam metal machine means you can increase your production efficiency while offering your clients high-quality, long-lasting roofing materials.

Why the Standing Seam Roofing Machine Is Essential for Your Business

The standing seam roofing machine is another must-have tool for roofing professionals looking to enhance their production capabilities. A standing seam roofing machine specializes in producing interlocking panels that are both attractive and functional. These panels are widely used due to their ability to expand and contract with temperature changes without compromising the roof's integrity.

The standing seam roofing machine is designed to form precise, smooth panels with tight seams that prevent leaks. This means you can produce roofs that are more durable and have a longer lifespan compared to traditional roofing methods. The machine's automation ensures high-quality results, minimizing human error and reducing production costs. If you're looking to stay competitive in the roofing industry, investing in a standing seam roofing machine is a smart decision that will pay off in both efficiency and product quality.

Maximize Efficiency with a Standing Seam Roof Machine

A standing seam roof machine is specifically designed to help manufacturers and contractors produce standing seam metal roofs with ease and precision. The standing seam roof machine forms the metal into panels with raised seams, which are then installed to create a seamless and durable roofing system. These machines are capable of producing high-quality roofing panels in a variety of lengths and profiles, ensuring that you can meet the unique needs of your projects.

The standing seam roof machine is designed for high-volume production, making it ideal for roofing companies that need to produce large quantities of roofing panels quickly. With its automated processes, the standing seam roof machine ensures uniformity in every panel, reducing the risk of errors and improving overall project timelines. Investing in a standing seam roof machine increases efficiency and allows roofing businesses to keep up with the growing demand for standing seam roofing systems.

The Future of Roofing: Standing Seam Machines

As the roofing industry evolves, so do the materials and equipment used to create durable, efficient, and aesthetically pleasing roofs. The demand for standing seam roofs is expected to continue to rise, making it crucial for roofing professionals to invest in the right equipment. Whether you’re looking for a standing seam machine for sale, a standing seam metal machine, a standing seam roofing machine, or a standing seam roof machine, now is the perfect time to upgrade your equipment.

These machines are not only designed to enhance your production capabilities, but they also enable you to produce high-quality roofing systems that stand the test of time. By investing in modern standing seam technology, you can reduce labor costs, speed up your production times, and offer your clients a roofing solution that meets the highest standards of durability and aesthetic appeal.

In conclusion, a standing seam machine for sale, a standing seam metal machine, a standing seam roofing machine, and a standing seam roof machine are essential tools for any roofing business looking to stay ahead in a competitive market. These machines offer exceptional precision, speed, and versatility, making them perfect for producing high-quality standing seam roofing panels. By investing in these machines, you can improve production efficiency, meet growing customer demand, and provide your clients with roofing systems that offer both durability and beauty.