Understanding U Channel Furring Forming Machines

In the modern construction and manufacturing industries, efficiency and precision are paramount. Among various machinery, the U channel furring forming machine has gained significant attention due to its pivotal role in producing U-shaped channels which are widely used in the construction of walls, ceilings, and various structural applications. This article will delve into the intricacies of U channel furring forming machines, their operations, applications, and benefits.

Overview of U Channel Furring Forming Machines

A U channel furring forming machine is specifically designed to produce U-shaped metal channels from flat metal sheets or coils. These machines cut, bend, and shape metal into precise dimensions, ensuring uniformity and quality in production. The U channels created by these machines are essential components in various building frameworks, providing structural support and facilitating the installation of drywall, insulation, and other materials.

Working Principles

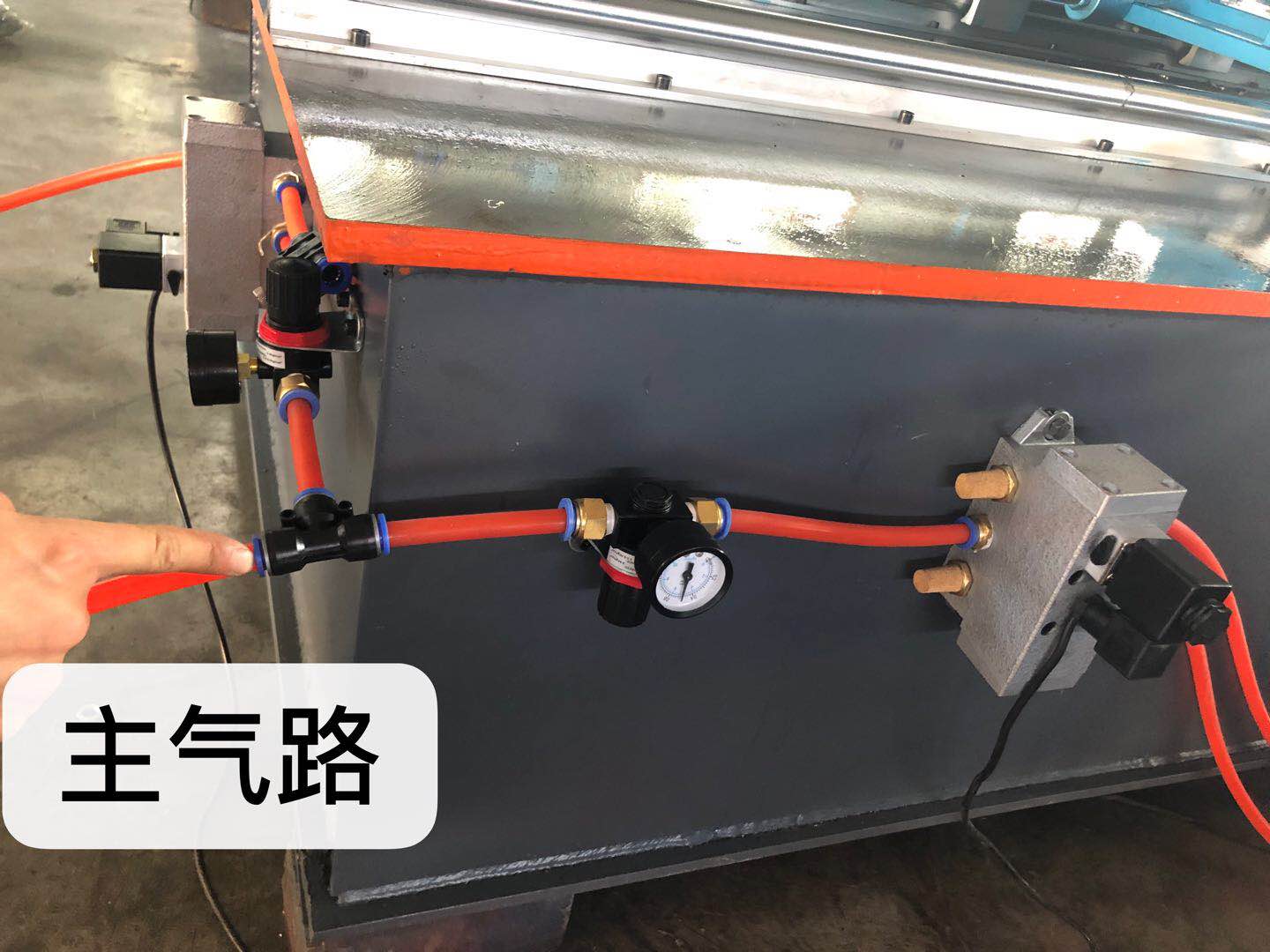

The operation of a U channel furring forming machine is a blend of several processes, including decoiling, feeding, forming, and cutting. Initially, flat metal coils are loaded onto a decoiler that unwinds the coils into manageable strips. These strips are then fed into the forming section of the machine, which consists of rollers and molds carefully designed to create the desired U shape.

As the metal strip passes through the rollers, it undergoes multiple bends, gradually taking the form of a U channel. Once the desired shape is achieved, the machine utilizes a cutting mechanism—either a shear or a blade—to cut the U channel to specified lengths. This process can be automated, allowing for high-volume production with minimal human intervention.

Applications

U channel furring forming machines are essential in various sectors, including

1. Construction They are frequently used for the installation of drywall systems, providing the necessary frame for sheets of gypsum board. 2. HVAC Systems U channels serve as supports for HVAC duct systems, ensuring proper airflow and structural integrity. 3. Electrical Wiring U channels are often utilized as raceways, allowing for safe and organized routing of electrical wiring in both residential and commercial buildings.

Benefits of U Channel Furring Forming Machines

Investing in a U channel furring forming machine brings an array of advantages

1. Cost Efficiency By automating the production of U channels, businesses can significantly reduce labor costs and minimize waste. The precision of the machine ensures that every cut and bend is accurate, leading to better material utilization.

2. High Production Speed These machines are designed for high volume output, capable of producing thousands of U channels in a short period. This increased productivity allows businesses to meet the demands of large projects efficiently.

3. Versatility U channel furring forming machines can handle various materials, including different types of metals. This adaptability makes them suitable for various projects, from residential homes to commercial buildings.

4. Quality Assurance With the ability to produce U channels with consistent specifications, these machines enhance the overall quality of construction projects. Uniformity in materials contributes to better structural integrity and aesthetic appeal.

5. Customizability Many advanced models of U channel forming machines come equipped with features that allow customization in terms of size, shape, and design. This flexibility caters to the unique requirements of different projects.

Conclusion

In summary, U channel furring forming machines play a crucial role in the construction and manufacturing industries. Their ability to produce high-quality, precise U channels efficiently makes them indispensable tools for modern construction. As technology continues to evolve, these machines are expected to become even more advanced, further enhancing productivity and quality in construction applications. By understanding and leveraging the capabilities of U channel furring forming machines, businesses can remain competitive in a rapidly changing industry landscape.