Understanding U-Channel Furring Forming Machines

In the realm of modern construction and interior design, precision and efficiency are of paramount importance. Among the various tools and machines that have revolutionized these fields, U-channel furring forming machines stand out due to their ability to create robust structures that support various building materials. This article delves into the functionality, advantages, and applications of U-channel furring forming machines.

What is a U-Channel Furring Forming Machine?

A U-channel furring forming machine is specially designed to produce U-shaped channels or furring strips from flat metal sheets. The formed channels are typically made from steel or aluminum, which makes them durable and ideal for various applications in construction and renovation. These machines utilize advanced technology to ensure that the channels are manufactured with great precision, consistent dimensions, and high-quality finishes.

Functionality

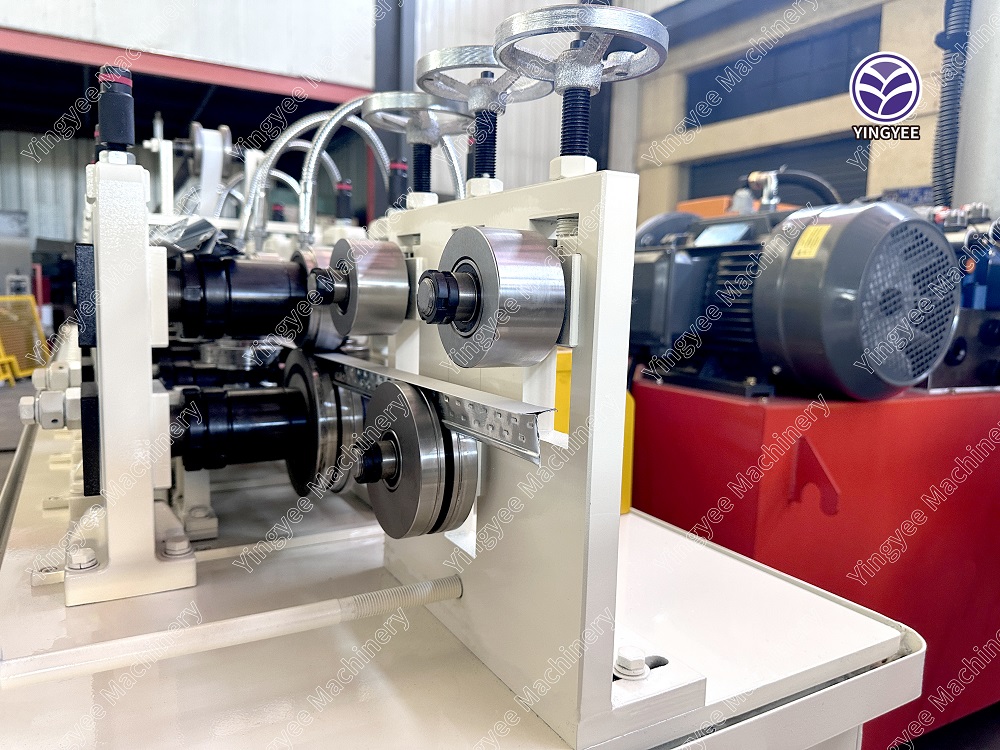

The operation of a U-channel furring forming machine is relatively straightforward. The process begins with the feeding of raw metal sheets into the machine. These sheets are then subjected to multiple forming rolls that progressively shape them into U-channels. Additional features may include a cutting mechanism that trims the channels to the required lengths, as well as the ability to create varying dimensions and thicknesses depending on project demands.

Some advanced models incorporate automated controls, which enhance efficiency and accuracy. These controls allow the machine to be easily programmed for different specifications, thus significantly reducing setup time for new production runs. Additionally, many machines are equipped with integrated safety features to protect operators and minimize accidents during operation.

Advantages of Using U-Channel Furring Forming Machines

1. Efficiency U-channel furring forming machines streamline the manufacturing process, enabling fast production rates. This efficiency is particularly beneficial in large construction projects where time is of the essence.

2. Precision The automated nature of these machines ensures that each channel produced meets exact specifications. This level of precision is crucial, as even minor discrepancies can lead to significant structural issues.

3. Cost-Effectiveness By minimizing waste and optimizing the use of materials, U-channel furring forming machines contribute to reduced manufacturing costs. Furthermore, the durability of the channels produced means fewer replacements and repairs are needed over time.

4. Versatility These machines can be adapted to produce various sizes and types of U-channels, making them suitable for a wide range of applications—from residential buildings to commercial infrastructures.

5. Quality Assurance The advanced technology used in these machines ensures that the U-channels produced are consistently high in quality, which is vital for maintaining a good reputation in the construction industry.

Applications

U-channel furring strips are integral to numerous applications. In interior construction, they are commonly used as supports for drywall and insulation, providing stability and a clean finish for walls and ceilings. Externally, U-channels can be found in frameworks for cladding, bridging, and roofing systems, assisting in the overall integrity of buildings.

Moreover, industries such as manufacturing, aerospace, and automotive also leverage U-channel furring strips for various parts and frameworks, showcasing the adaptability of this product across sectors.

Conclusion

In summary, the U-channel furring forming machine plays a crucial role in modern construction and manufacturing processes. Its ability to produce high-quality, precise U-channels efficiently makes it an indispensable tool for builders and manufacturers alike. As the demand for quicker, more effective construction methods continues to rise, the importance of such technologies will only grow, paving the way for advancements in the industry. By investing in U-channel furring forming machines, businesses can significantly enhance their workflow and contribute to the evolution of construction methodologies.