Two-Layer Step Tile Corrugated Arc Machine An Innovative Solution for Modern Roofing

In the ever-evolving construction industry, the need for efficient, durable, and aesthetically pleasing roofing solutions has never been more critical. The Two-Layer Step Tile Corrugated Arc Machine is a groundbreaking innovation designed to meet these demands, offering a versatile approach to roof design and construction. This machine not only enhances the quality of roofing materials but also improves production efficiency, making it a valuable asset for manufacturers and construction professionals alike.

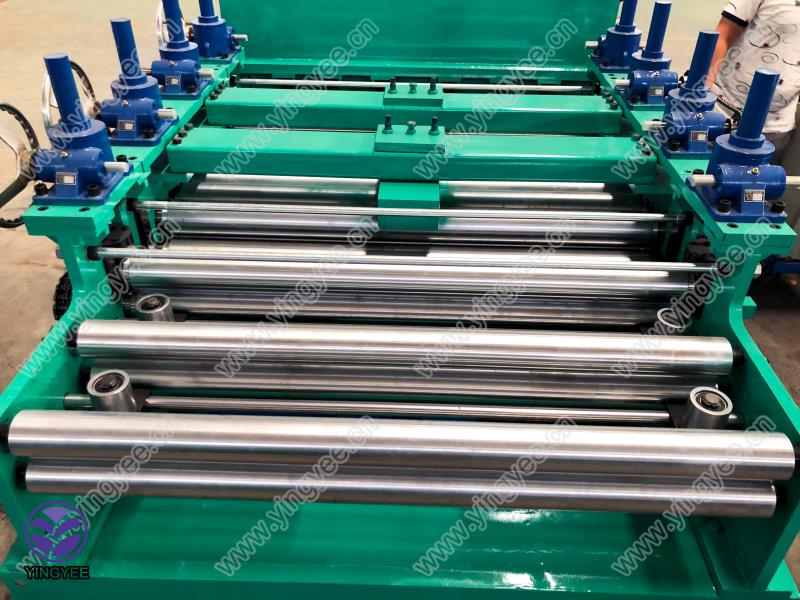

Understanding the Machine

The Two-Layer Step Tile Corrugated Arc Machine is engineered to produce advanced roofing tiles that combine structural integrity with visual appeal. This machine operates by simultaneously forming two layers of roofing material, allowing for the creation of tiles that exhibit both a robust design and a distinctive aesthetic profile. The double-layer production technique ensures that the tiles are not only lightweight but also resistant to various environmental factors such as moisture, UV radiation, and temperature fluctuations.

One of the key features of this machine is its ability to create corrugated and arc-shaped tiles. The unique designs generated by the machine allow for innovative roofing styles that can dramatically enhance the visual appeal of residential and commercial buildings. With the ability to produce tiles in various colors and finishes, architects and designers can exercise greater creativity in their projects.

Efficiency and Flexibility

The Two-Layer Step Tile Corrugated Arc Machine is designed with efficiency in mind. The use of advanced technology in its operation means that the production cycle is significantly shortened compared to traditional methods. Manufacturers can produce a higher volume of tiles in less time, which not only increases output but also reduces labor costs.

Moreover, the machine offers remarkable flexibility in terms of customization. Operators can easily adjust the specifications to produce tiles of varying sizes, shapes, and thicknesses, allowing for tailored solutions that meet specific project requirements. This flexibility is particularly beneficial in a market that increasingly demands unique and personalized designs.

Quality and Durability

Quality is a paramount concern in roofing, as it directly impacts the safety and longevity of a building. The Two-Layer Step Tile Corrugated Arc Machine addresses this concern by ensuring that each tile produced meets strict quality standards. The double-layer construction enhances the durability of the tiles, making them less prone to cracking or fading over time. Additionally, the machine allows for the incorporation of various additives into the production process, further enhancing the tiles' resistance to weathering and wear.

Environmental Considerations

In today's environmentally conscious market, sustainability is a crucial aspect of production. The Two-Layer Step Tile Corrugated Arc Machine plays a role in promoting eco-friendly practices within the roofing industry. By optimizing material usage and reducing waste during the production process, this machine contributes to more sustainable manufacturing practices. Furthermore, the durability of the tiles produced means they have a longer lifespan, reducing the need for frequent replacements and minimizing material waste over time.

Conclusion

The Two-Layer Step Tile Corrugated Arc Machine represents a significant advancement in roofing technology. Its ability to produce high-quality, aesthetically pleasing tiles with enhanced durability and efficiency makes it an indispensable tool for manufacturers in the construction industry. As the demand for innovative roofing solutions continues to rise, this machine stands out as a key player in meeting those needs, paving the way for more sustainable and creative building designs. Embracing such technologies is essential for those looking to stay ahead in a competitive market while contributing to a more sustainable future.