Trapezoid Roof Sheet Roll Forming Machine A Comprehensive Overview

The trapezoid roof sheet roll forming machine is an advanced piece of equipment that has significantly transformed the manufacturing industry, particularly in the production of roofing materials. This innovative machine is designed to produce high-quality trapezoidal roof sheets, which are widely used in the construction of commercial and industrial buildings due to their excellent durability and aesthetic appeal.

The Mechanism of Roll Forming

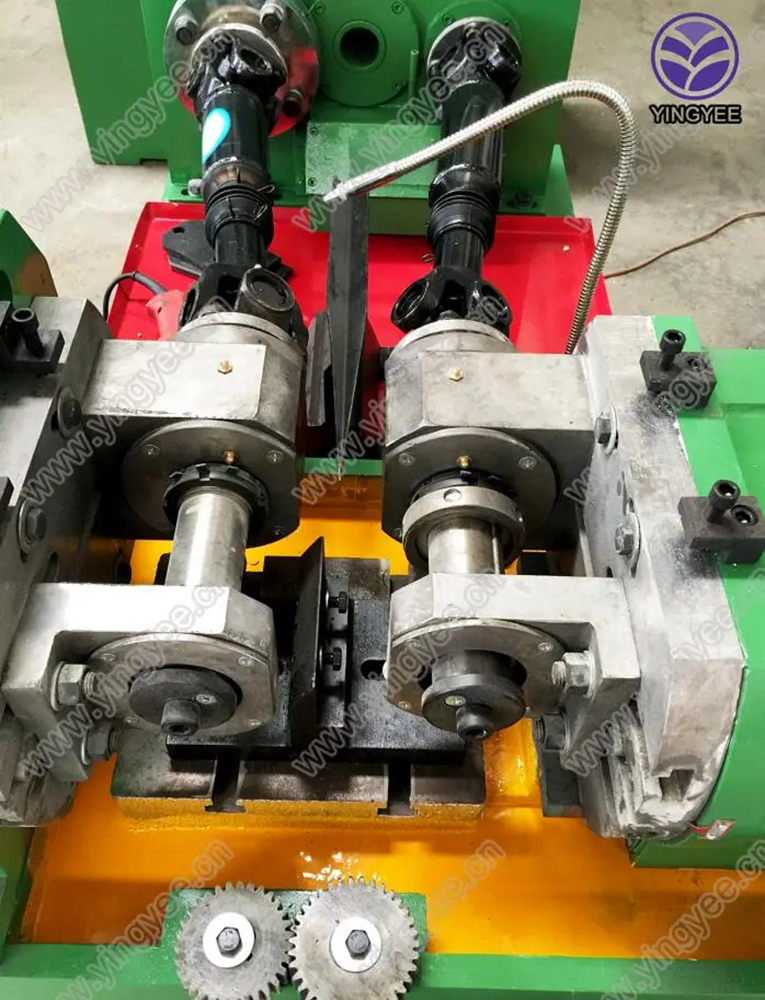

At the heart of the trapezoid roof sheet roll forming machine is the roll forming process itself. This method involves feeding a continuous coil of metal through a series of rollers, which gradually shape the material into the desired cross-section. The trapezoidal profile is achieved through a carefully designed series of rollers that bend and cut the metal sheet to precise specifications. This process is not only efficient but also allows for consistent and uniform production of roof sheets.

The machine typically consists of several key components a decoiler, roll forming system, hydraulic cutting system, and control system. The decoiler releases the metal coil and feeds it into the forming system, where the rollers perform their work. The hydraulic cutting system ensures that the sheets are cut to the exact lengths required, while the control system allows for easy operation and monitoring of the entire process.

Advantages of Using Trapezoid Roof Sheet Roll Forming Machines

1. High Efficiency One of the most significant advantages of using this type of machine is its efficiency. The roll forming process can produce large quantities of trapezoidal sheets in a short period, making it ideal for manufacturers looking to meet high demand.

2. Cost-Effective Production With reduced material waste and faster production times, the overall cost of manufacturing trapezoidal roof sheets is significantly lower compared to traditional methods. This economic benefit makes it an attractive investment for manufacturing companies.

3. Customization Many roll forming machines offer customization options that allow manufacturers to produce roof sheets in various sizes, colors, and thicknesses. This flexibility caters to the diverse needs of different projects and customers.

4. Durability and Quality The trapezoid roof sheets produced are renowned for their strength and durability, capable of withstanding harsh weather conditions. Additionally, roll forming machines ensure a uniform quality, reducing the likelihood of defects.

5. Ease of Operation Modern trapezoid roof sheet roll forming machines come equipped with advanced control systems for easy operation and monitoring. Operators can set parameters quickly and efficiently, improving overall productivity.

Applications in the Construction Industry

Trapezoidal roof sheets have become a preferred choice in the construction industry for several reasons. Their unique shape allows for efficient drainage of rainwater, reducing the risk of water accumulation and subsequent damage. These sheets are commonly used in warehouses, factories, commercial buildings, and even residential complexes due to their structural integrity and weather resistance.

Additionally, their sleek design enhances the aesthetic appeal of buildings, making them suitable for both functional and architectural applications. As the demand for sustainable and cost-effective construction materials continues to grow, the importance of trapezoid roof sheet roll forming machines is expected to increase.

Conclusion

In conclusion, the trapezoid roof sheet roll forming machine is a vital tool in modern manufacturing, offering high efficiency, customization options, and durability. As the construction industry evolves, these machines will continue to play a crucial role in meeting the growing demand for quality roofing materials, contributing to sustainable building practices and ultimately shaping the skylines of the future.