Trapezoid Roof Sheet Forming Machine Revolutionizing Roofing Solutions

In the construction industry, efficiency and durability are paramount, especially when it comes to roofing solutions. One of the innovative tools making waves is the trapezoid roof sheet forming machine. This sophisticated equipment is designed to streamline the manufacturing process of trapezoidal metal roofing sheets, which are favored for their strength and aesthetic appeal.

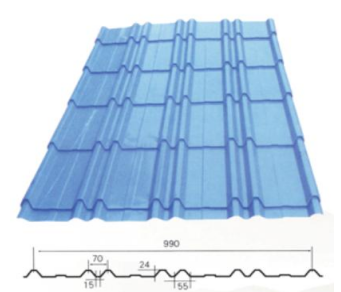

A trapezoid roof sheet is characterized by its angular design, which not only enhances the visual appeal of buildings but also facilitates effective water drainage. The trapezoidal shape provides added structural support, making these sheets ideal for various applications, from residential homes to commercial buildings and industrial facilities.

The trapezoid roof sheet forming machine utilizes advanced technology to convert raw metal coils into finished roofing sheets. This process begins with the uncoiling of steel or aluminum sheets, which are then fed into the forming machine. The machine bends and shapes the metal into specific trapezoidal profiles using a series of rollers. One of the key advantages of this machinery is its precision; it ensures uniformity in dimensions, thickness, and shape for each sheet produced.

Efficiency is another significant benefit. Traditional roofing solutions often involved labor-intensive methods that were time-consuming and prone to errors. With a trapezoid roof sheet forming machine, production speeds are greatly increased, allowing manufacturers to meet high-demand requirements without compromising quality. Furthermore, these machines can be easily adjusted to create various sizes and styles, making them highly versatile for different projects.

In addition to efficiency and versatility, the quality of the roofing sheets produced is superior. The finished trapezoid sheets are robust, resistant to weather damage, and capable of withstanding extreme temperatures. This durability translates into a longer lifespan for roofs, reducing the need for frequent repairs or replacements.

Moreover, the trend towards sustainable construction practices is being embraced by the use of trapezoid roof sheet forming machines. Many manufacturers are opting for recycled materials to produce these sheets, thereby minimizing environmental impacts and promoting eco-friendly building. This not only helps in conserving resources but also appeals to environmentally conscious consumers.

In conclusion, the trapezoid roof sheet forming machine represents a significant advancement in roofing technology. Its ability to efficiently produce high-quality, durable roofing sheets makes it an essential tool for modern construction. As the industry continues to evolve, the demand for such innovative solutions will likely grow, paving the way for a future where construction processes are faster, more efficient, and environmentally sustainable. Whether one is constructing a new building or renovating an old one, trapezoid roofing sheets offer both practicality and style—a combination that is hard to beat.