Understanding C Purlin Manufacturers A Key Component in Industrial Construction

C purlins are essential structural components widely used in the construction industry. Their versatility and strength make them a preferred choice among engineers and builders for various applications, including warehouses, agricultural buildings, and commercial structures. In recent years, the demand for C purlin manufacturers has surged, driven by growth in construction activities and an increasing emphasis on sustainable building practices. This article explores the significance of C purlin manufacturers, their production processes, and the benefits they offer to the construction industry.

What are C Purlins?

C purlins are horizontal structural members shaped like the letter C. They are typically made from cold-formed steel and are used to support roof and wall systems in various buildings. The design allows them to efficiently transfer loads to vertical supports, making them critical components in both load-bearing and non-load-bearing structures. C purlins are available in various sizes and gauges, which can be customized according to specific project requirements.

The Role of C Purlin Manufacturers

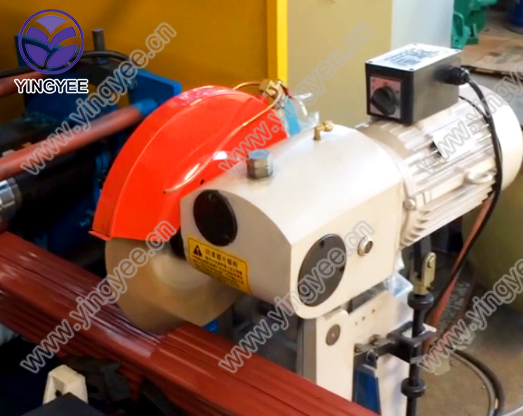

C purlin manufacturers play a vital role in the construction industry by producing high-quality purlins that meet industry standards and specifications. The manufacturing process typically involves high-tech machinery and advanced techniques to ensure precision and durability. Manufacturers must adhere to strict quality control measures to ensure that their products can withstand the forces and loads encountered in real-world applications.

These manufacturers often utilize cold-formed techniques, which not only enhance the strength-to-weight ratio of the purlins but also reduce material waste. This emphasis on efficiency and sustainability is increasingly important in today’s construction landscape, where eco-friendly practices are a growing concern.

Advantages of Using C Purlins

1. Lightweight Yet Strong One of the key advantages of C purlins is their lightweight nature, which reduces the overall load of the structure. This can lead to savings in foundation and support costs. Despite being lightweight, C purlins are extremely strong and can handle significant loads.

2. Cost-Effective C purlins are generally more affordable than other structural components. Their efficient manufacturing process and material usage contribute to lower costs, making them an attractive option for builders and developers.

3. Versatility C purlins can be used in a variety of applications, from industrial buildings to residential structures. Their adaptability means they can be utilized in various construction scenarios, including roofing, wall bracing, and as part of framed structures.

4. Ease of Installation The design of C purlins allows for quicker installation compared to traditional materials. Their lightweight and modular nature make them easier to handle and transport, saving time on construction sites.

5. Durability and Longevity C purlins made from galvanized steel are resistant to rust and corrosion, ensuring they maintain their structural integrity over time. This durability is crucial for long-term investment in any construction project.

Conclusion

C purlin manufacturers play an indispensable role in modern construction, providing essential components that contribute to the strength, durability, and efficiency of buildings. With their lightweight and versatile design, C purlins are increasingly favored in a variety of applications, offering builders a cost-effective and sustainable solution. As the construction industry continues to evolve, the demand for high-quality C purlins from reputable manufacturers will likely grow, reinforcing their significance in the building landscape. Whether it’s for a commercial warehouse or a residential garage, the contributions of C purlins cannot be overlooked, marking a crucial element in the framework of contemporary architecture.