The Tile Roof Machine Revolutionizing the Roofing Industry

In the ever-evolving construction and roofing sectors, efficiency and quality are paramount. One of the most significant innovations to revolutionize these industries is the tile roof machine. This remarkable piece of equipment has transformed how roofing tiles are manufactured, allowing for a faster, more cost-effective, and sustainable approach to roofing.

Tile roofs are renowned for their durability, aesthetic appeal, and excellent weather resistance, making them a popular choice in both residential and commercial construction. However, the traditional methods of producing roofing tiles can be labor-intensive, time-consuming, and often lead to inconsistencies in quality. This is where the tile roof machine comes into play, simplifying the production process while ensuring high-quality outputs.

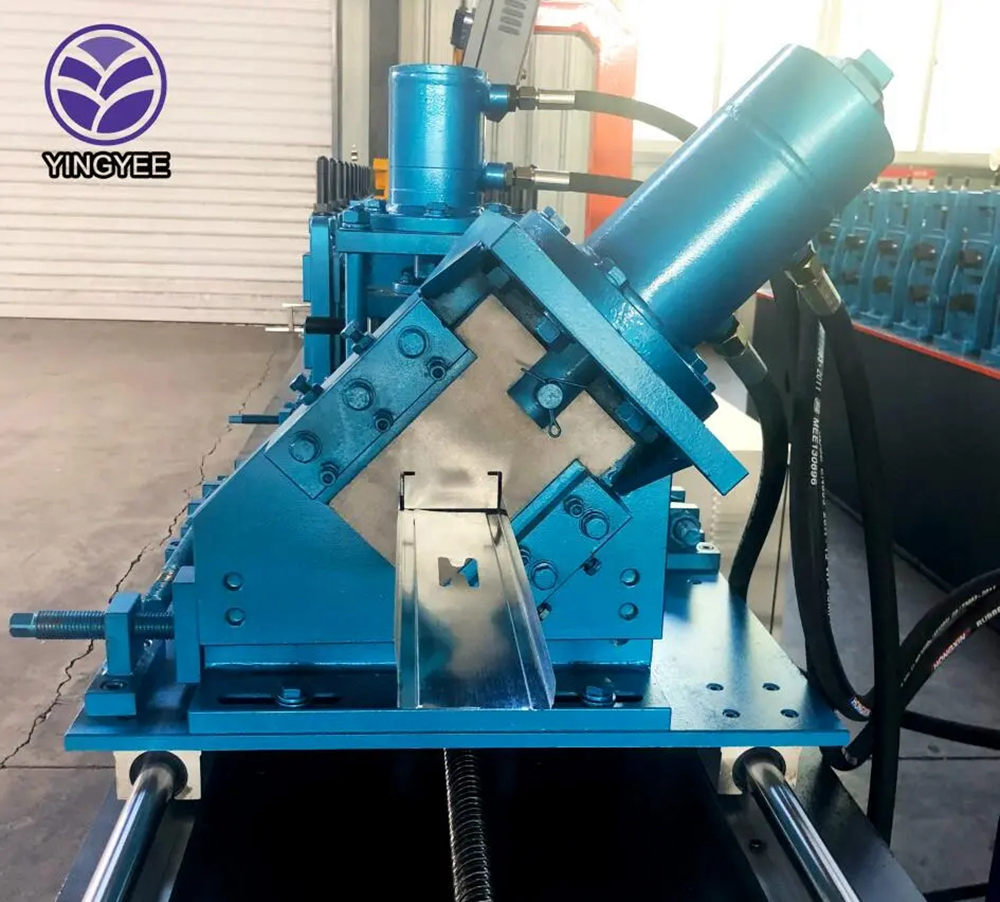

A tile roof machine typically operates through a series of automated processes that include mixing raw materials, shaping, drying, and firing tiles. The machine is designed to handle various types of materials like clay, concrete, and even synthetic options. This versatility allows roofing contractors to choose materials based on their specific project needs, ensuring that they can meet different aesthetic and performance criteria.

One of the key advantages of using a tile roof machine is the significant reduction in production time. Traditional tile manufacturing can take several days or even weeks to complete, especially when working with manual processes. In contrast, automated tile machines can produce large quantities of roofing tiles in a fraction of the time. This efficiency means that contractors can complete projects faster, thus increasing their profit margins and satisfying client demand for timely deliveries.

Moreover, the consistency in the quality of tiles produced by these machines is unparalleled. Automated machines follow precise specifications, resulting in uniform tile sizes, shapes, and colors. This consistency not only enhances the overall appearance of a finished project but also ensures better performance in terms of durability and weather resistance. Clients can rest assured that the tiles installed on their roofs will perform well over time, minimizing the need for repairs or replacements.

The environmental benefits of tile roof machines cannot be overlooked. Many of these machines are designed to operate with energy efficiency in mind, often using renewable energy sources whenever possible. Furthermore, the ability to use recycled materials in the production of tiles contributes to sustainability efforts within the construction industry. When combined with the longevity of tile roofs themselves, which can last for decades with minimal maintenance, the environmental impact is significantly reduced.

In addition to production efficiency and sustainability, the tile roof machine opens up new possibilities for design and customization. Advanced technology allows for the creation of various tile styles, colors, and finishes, catering to a wide range of architectural preferences. Whether it's a traditional Mediterranean style or a modern minimalist look, contractors can offer their clients an array of choices without compromising on quality.

As the demand for effective and aesthetically pleasing roofing solutions continues to grow, the tile roof machine stands out as a vital component in the construction landscape. Its ability to streamline the production process, ensure high-quality output, and promote sustainability makes it an indispensable tool for roofing professionals.

In conclusion, the innovation of the tile roof machine is a testament to how technology can enhance traditional industries. By embracing automation, the roofing sector not only meets the demands of modern construction but also sets a foundation for more sustainable practices. As technology advances further, we can anticipate even more remarkable developments within the realm of roofing, paving the way for a brighter, more efficient future in the construction industry.