Understanding Tile Roll Forming Machines A Comprehensive Overview

Tile roll forming machines are essential tools in the construction and manufacturing industries, specifically designed to produce high-quality metal roofing tiles. These machines utilize advanced technological processes to transform flat metal sheets into beautifully designed tiles that mimic the appearance of traditional roofing materials, such as ceramic or slate, but with enhanced durability and lower maintenance.

How Tile Roll Forming Machines Work

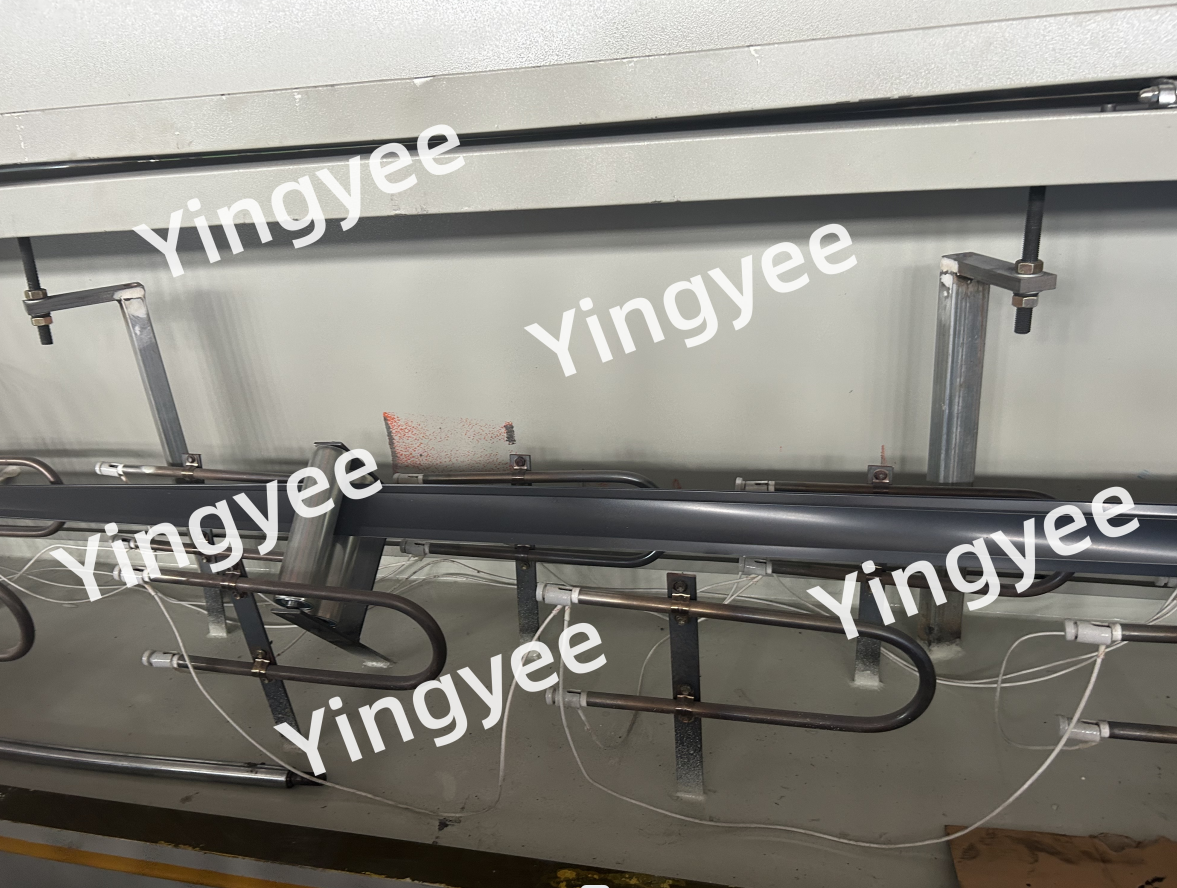

Tile roll forming machines employ a series of rollers to shape metal coils into pre-defined profiles. The process begins with feeding a flat metal sheet into the machine, where it is gradually fed through multiple sets of rollers. Each set of rollers gently bends and forms the metal, transitioning it from a flat surface to a corrugated or tiled appearance, depending on the desired end product.

The machine's precision engineering allows for consistent and repeatable results, ensuring each tile meets stringent industry standards. Most tile roll forming machines are equipped with computerized controls that enable operators to adjust parameters like width, thickness, and shape easily.

Benefits of Tile Roll Forming Machines

One of the main advantages of using tile roll forming machines is the speed at which they operate. Unlike traditional tile manufacturing methods, which can be time-consuming and labor-intensive, these machines can produce large volumes of tiles in a fraction of the time. This efficiency not only reduces labor costs but also accelerates project timelines, making them highly appealing to contractors and builders.

Additionally, the tiles produced by roll forming machines are remarkably lightweight yet robust. They offer excellent resistance to harsh weather conditions, such as heavy rain, snow, and high winds. This resilience contributes to the longevity of roofs, reducing replacement and maintenance costs over time.

Another significant benefit is the versatility of tile roll forming machines. They can process various materials, including aluminum, galvanized steel, and other alloys, allowing manufacturers to create tiles with different aesthetic finishes and functional properties. This flexibility enables customization for specific projects, catering to the diverse needs of clients.

Applications in the Construction Industry

The demand for tile roll forming machines is constantly growing due to the increasing popularity of metal roofing. Homeowners and builders alike appreciate the aesthetic appeal of metal tiles, which come in a variety of colors and styles. Additionally, their energy-efficient properties contribute to better insulation, promoting environmentally friendly building practices.

These machines are not limited to residential projects; they are also widely used in commercial construction. Metal roofing tiles provide excellent fire resistance, making them an ideal choice for structures requiring stringent safety measures. Furthermore, they have a high recyclability rate, contributing to sustainable building practices.

Conclusion

In summary, tile roll forming machines play a pivotal role in modern construction and manufacturing. Their ability to create high-quality, durable roofing tiles quickly and efficiently addresses the growing demand for metal roofing solutions. With numerous advantages, such as speed, versatility, and strength, these machines are invaluable to builders and manufacturers looking to stay ahead in a competitive market. As technology advances, we can expect continued innovation in tile roll forming, further enhancing the capabilities and efficiency of these essential machines.