The Tile Machine Revolutionizing the Tile Industry

In the realm of construction and interior design, the use of tiles has become a fundamental aspect of creating aesthetically pleasing and functional spaces. From residential homes to commercial buildings, tiles serve both practical and decorative purposes. However, the process of manufacturing and laying tiles has traditionally been labor-intensive, often resulting in increased costs and time delays. Enter the tile machine—a technological innovation that is transforming the tile industry and reshaping the way tiles are produced and installed.

The Evolution of Tile Machines

Historically, tile production involved manual labor and basic machinery, which limited efficiency and consistency. As the demand for high-quality tiles grew alongside architectural advancements, the industry recognized the need for more sophisticated manufacturing solutions. The evolution of tile machines has catered to this need, leading to the development of automated systems that enhance precision and efficiency.

Modern tile machines utilize cutting-edge technology, such as Computer Numerical Control (CNC) and robotics, to automate the production process. This automation ensures that tiles are produced with remarkable consistency, reducing defects significantly. The use of advanced materials and techniques also allows for the creation of intricate designs that were once impossible to achieve with manual methods.

Advantages of Using Tile Machines

1. Increased Production Speed One of the most significant benefits of tile machines is their ability to produce large volumes of tiles at an impressive speed. Traditional methods could take days to complete a batch, while automated machines can produce them in a matter of hours. This increase in efficiency not only meets market demands but also reduces overall production costs.

2. Enhanced Quality Control Tile machines are equipped with advanced sensors and monitoring systems that ensure each tile meets strict quality standards. Variations in size, shape, and color can be minimized, providing consumers with tiles that are uniform and reliable. This consistency is crucial not only for aesthetic purposes but also for ensuring proper installation.

3. Customization The flexibility of modern tile machines allows for greater customization. Manufacturers can easily adjust settings to create tiles in various sizes, shapes, colors, and textures. This capability has led to an explosion of creative possibilities in tile design, enabling architects and designers to push creative boundaries.

4. Sustainability With growing concerns about environmental impact, many tile machines are designed to be more energy-efficient and produce less waste than traditional methods. Innovations in recycling materials and reducing water usage during production help create a more sustainable tile manufacturing process. As consumers become increasingly eco-conscious, the demand for sustainable practices in the tile industry continues to rise.

The Installation Revolution

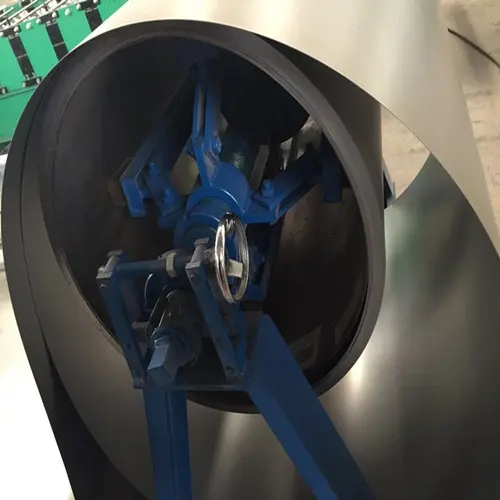

The innovation of tile machines extends beyond manufacturing; it also significantly impacts the installation process. Automated tile laying systems are becoming more prevalent, which streamline the installation phase by ensuring precise alignment and even spacing. These systems not only speed up the installation process but also reduce the likelihood of human error, leading to superior finished results.

Moreover, tile machines can efficiently handle large, heavy tiles that would be challenging for workers to manage. This capability allows for the popularization of large-format tiles, which can create striking visual effects when installed as flooring or wall coverings.

The Future of Tile Machines

As technology continues to evolve, the tile industry is likely to see even more advancements in tile machines. Incorporating artificial intelligence (AI) and machine learning could further enhance production processes, making them smarter and more adaptable. The integration of these technologies may enable manufacturers to predict trends and adjust production accordingly, ensuring they meet market demands instantly.

The future of tile machines promises to be bright, with numerous opportunities for innovation and enhancement. By embracing these advancements, the tile industry can continue to evolve, providing consumers with high-quality, aesthetically pleasing, and sustainable tile options.

In conclusion, the advent of tile machines represents a seismic shift in the tile manufacturing and installation process. By increasing efficiency, improving quality, offering customization, and promoting sustainability, these machines are revolutionizing the tile industry, making tile a more accessible and desirable choice for consumers worldwide. As the industry continues to embrace technological advancements, we can expect to see further exciting developments in tile design and production.