Tile Arc Steel Sheet Roll Forming Machine Revolutionizing Construction

In today’s rapidly evolving construction industry, efficiency, precision, and sustainability are paramount. The Tile Arc Steel Sheet Roll Forming Machine is a breakthrough technology that addresses these needs, providing significant benefits for manufacturers and end-users alike.

Understanding Roll Forming Technology

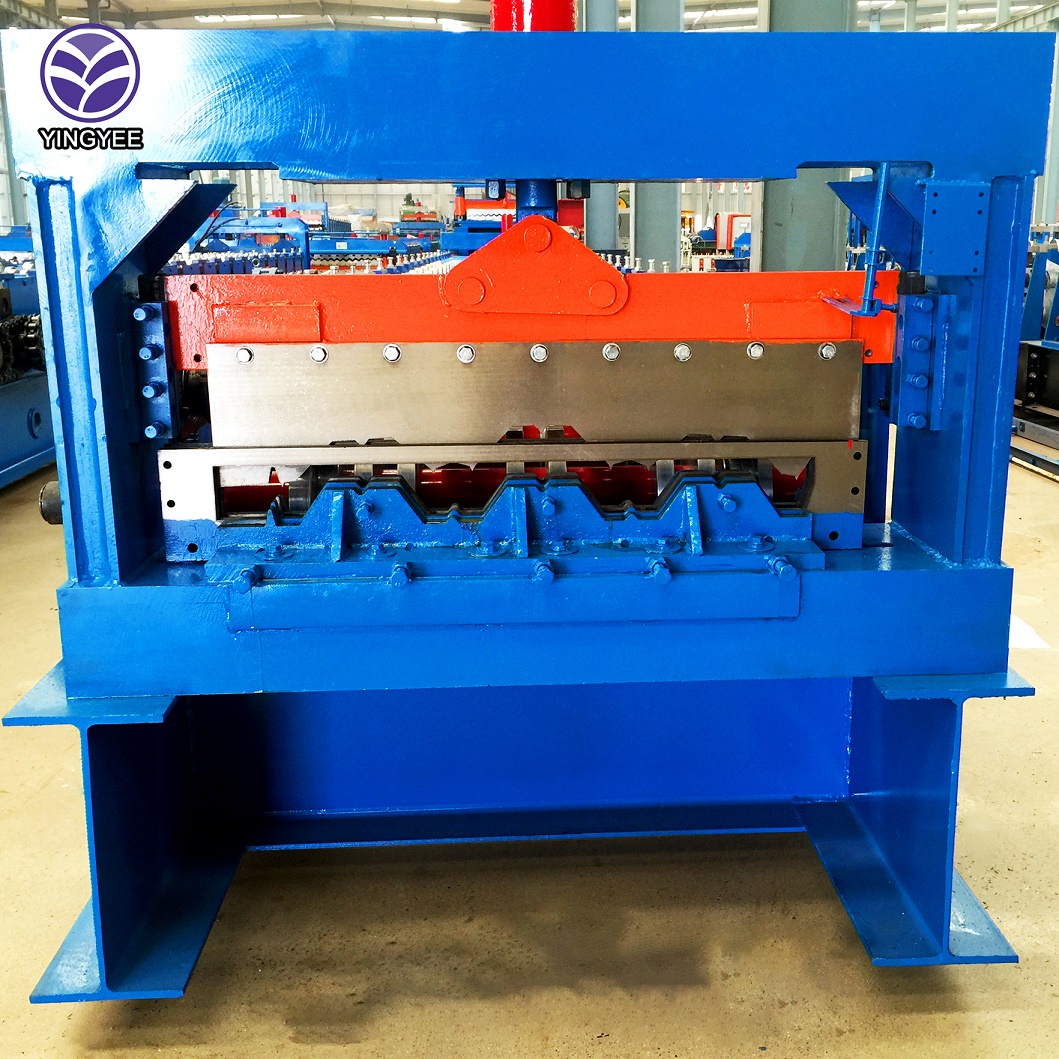

Roll forming is a severe process in which metal strips are continuously and gradually shaped into desired profiles through a series of rollers. This process is known for its ability to produce complex shapes with high accuracy while maintaining the integrity of the material. The Tile Arc Steel Sheet Roll Forming Machine specifically caters to the production of arc-shaped steel sheets, which are increasingly utilized in roofing, cladding, and various architectural applications.

Advantages of Tile Arc Steel Sheet Roll Forming Machines

1. Efficiency and Speed One of the primary advantages of this machine is its ability to produce large quantities of steel sheets in a short time. The roll forming process minimizes waste and maximizes output, allowing manufacturers to meet the growing demand for construction materials without compromising quality.

2. Customization The Tile Arc Steel Sheet Roll Forming Machine can be designed to produce various profiles and dimensions. This flexibility means that manufacturers can tailor products to specific project requirements, enabling them to serve a diverse range of customers.

3. Durability and Strength Steel has long been recognized for its outstanding strength-to-weight ratio. Arc-shaped steel sheets produced by these machines are particularly durable, making them ideal for structures that require both aesthetic appeal and structural integrity.

4. Cost-Effectiveness By reducing material waste and improving production efficiency, the Tile Arc Steel Sheet Roll Forming Machine offers an economical solution for manufacturers. Moreover, the durability of the products reduces the need for frequent maintenance or replacement, providing long-term savings for end-users.

5. Sustainability As the construction industry moves towards greener practices, the use of steel as a recyclable material aligns perfectly with sustainability goals. The roll forming process itself is energy-efficient, and the products can be recycled at the end of their life cycle, contributing to reduced environmental impact.

Applications in the Construction Industry

The arc-shaped steel sheets produced by these machines have a wide range of applications in the construction sector. They are often used in roofing systems, where their curved design not only enhances the aesthetic appeal but also improves water drainage and wind resistance. Additionally, they are utilized in wall cladding, creating visually striking facades while providing excellent protection against the elements.

Moreover, these sheets are perfect for industrial buildings, agricultural facilities, and residential projects where versatility and resilience are required. The ability to create custom profiles means that they can meet various design preferences and functional demands.

Conclusion

The Tile Arc Steel Sheet Roll Forming Machine marks a significant advancement in construction technology. With its blend of efficiency, precision, and versatility, it not only streamlines the production process but also elevates the quality of construction materials. As the industry continues to evolve, machines like these will play a crucial role in meeting the demands of modern architecture while promoting sustainable practices. Investing in such technology is not just a step forward for manufacturers but a leap towards a more innovative and sustainable construction future.