The Tile Arc Steel Sheet Roll Forming Machine Revolutionizing Construction and Manufacturing

In the modern age of construction and manufacturing, the demand for high-quality building materials has soared. Among the various solutions available, the tile arc steel sheet roll forming machine stands out as a revolutionary tool that significantly enhances efficiency and quality. This machine is designed to produce arched steel sheets that are widely used in roofing, cladding, and various structural applications.

What Is a Tile Arc Steel Sheet Roll Forming Machine?

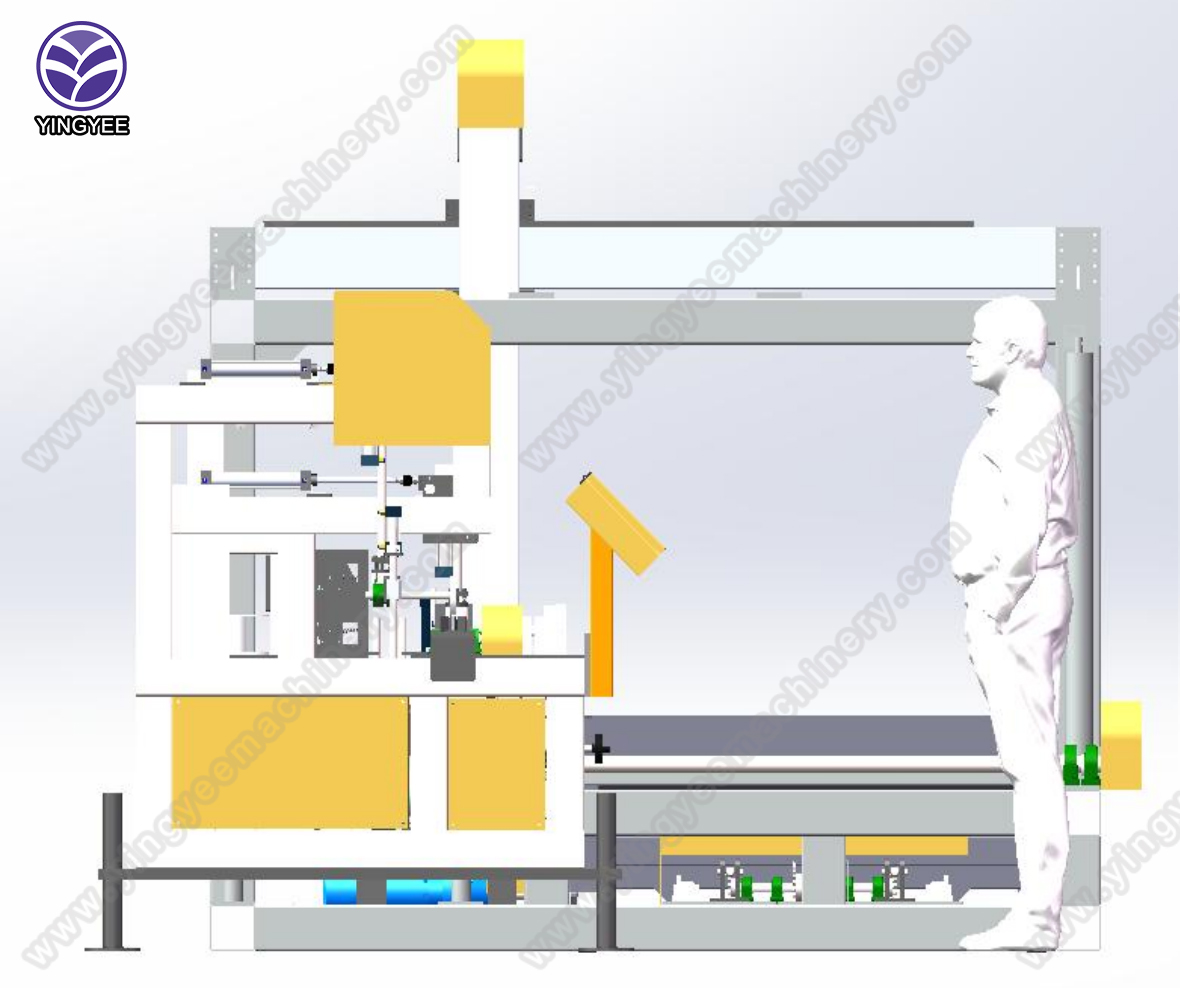

At its core, the tile arc steel sheet roll forming machine is a specialized piece of equipment that converts flat steel sheets into curved, tile-like profiles. These profiles mimic the traditional tile appearance while providing the durability and strength of steel. The machine operates through a series of rollers that gradually shape the flat sheet into the desired arc form. This process not only saves time and labor but also ensures that the final product meets strict dimensional and quality standards.

Key Features and Benefits

1. Precision Engineering One of the most significant advantages of the tile arc steel sheet roll forming machine is its precision. The machine is equipped with advanced technologies, such as computerized controls and high-precision rollers, which ensure that each sheet produced is consistent in size and shape. This precision reduces waste and minimizes the need for rework, saving both time and resources.

2. High Production Efficiency With the ability to process large quantities of steel sheets in a relatively short time, these machines significantly boost production efficiency. Manufacturers can rely on the machine to produce arched steel sheets at a rapid pace without compromising quality. This efficiency is vital in meeting the demands of fast-paced construction projects and helps companies maintain a competitive edge in the market.

3. Versatility in Design The tile arc steel sheet roll forming machine is highly versatile, capable of producing a variety of designs. This versatility allows manufacturers to cater to different architectural styles and customer preferences. Whether it’s a gentle curve for a traditional roof or a more pronounced arch for a modern structure, the machine can be adjusted to create the desired profile.

4. Cost-Effectiveness Investing in a tile arc steel sheet roll forming machine can lead to significant cost savings in the long run. By streamlining the production process and minimizing waste, businesses can lower their overall manufacturing costs. Additionally, the durability of steel sheets reduces maintenance expenses over time, making it a wise investment for builders and manufacturers alike.

Applications in Construction

The applications of tile arc steel sheets are vast. In the construction industry, these sheets are predominantly used for roofing, providing not only aesthetic appeal but also excellent weather resistance. Their unique curvature helps in efficiently draining rainwater, thereby minimizing the risk of leaks and structural damage.

Furthermore, tile arc steel sheets are also used in the construction of warehouses, agricultural buildings, and industrial facilities. They offer a lightweight yet sturdy option for cladding, enabling architects and builders to design structures that are both functional and visually pleasing.

Environmental Considerations

In an era where sustainability is paramount, the use of steel in construction increasingly aligns with eco-friendly practices. Steel is recyclable, and utilizing a machine that converts steel sheets into desirable shapes reduces the need for additional materials. Furthermore, the longevity of steel structures means that less frequent replacements are required, contributing to lower overall environmental impact.

Conclusion

The tile arc steel sheet roll forming machine is a game-changer in the construction and manufacturing sectors. The combination of precision, efficiency, and versatility makes it an essential tool for producing high-quality arched steel sheets. As the demand for durable and aesthetically pleasing building materials continues to rise, these machines will play a critical role in shaping the future of construction. By embracing such advanced technologies, companies can enhance their productivity, reduce costs, and contribute to a more sustainable building environment. In summary, the tile arc steel sheet roll forming machine stands as a testament to innovation and efficiency in the ever-evolving world of construction and manufacturing.