The Three Wave & Guardrail Making Machine Revolutionizing Infrastructure Production

In the ever-evolving world of infrastructure development, efficiency and quality are paramount. One of the technological advancements that have significantly influenced this sector is the introduction of specialized machinery for producing guardrails — particularly, the Three Wave & Guardrail Making Machine. This innovative piece of equipment not only enhances the production process but also ensures that the end products meet stringent safety and quality standards.

Understanding the Need for Guardrails

Guardrails play a crucial role in road safety, acting as a barrier to prevent vehicles from leaving the roadway during accidents or loss of control. Their design and construction must comply with safety regulations and standards to minimize the risk of injury or damage. As urbanization accelerates and traffic volumes increase, the demand for effective guardrails has surged, prompting manufacturers to develop efficient production techniques.

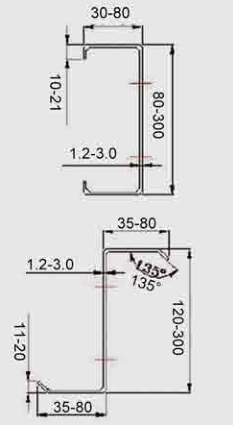

The Role of Three Wave Design

The three wave design refers to the corrugated shape of the guardrail, which is engineered to absorb impact energy more effectively. This shape enhances the structural integrity of the guardrail, allowing it to withstand greater forces while maintaining protective functionality. The production of these three-wave guardrails requires precision machinery tailored for the task.

Features of the Three Wave & Guardrail Making Machine

The Three Wave & Guardrail Making Machine is designed with innovation and efficiency in mind

. Some key features of this machine include1. Automated Production The machine incorporates advanced technology to automate various stages of the manufacturing process. This not only speeds up production but also minimizes the risk of human error.

2. Material Versatility Designed to work with a variety of materials, including steel and aluminum, the machine can produce guardrails that meet different specifications and performance standards.

3. Customization Capabilities The machine allows for customization in terms of length, thickness, and coating options, enabling manufacturers to tailor products to specific client needs or regulatory requirements.

4. Energy Efficiency Modern designs prioritize energy efficiency, consuming less power while maintaining high output levels. This feature not only reduces operational costs but also lessens the environmental impact.

5. User-Friendly Interface Incorporating a digital control system, the machine is easier to operate, allowing for quick adjustments and real-time monitoring of production processes.

Benefits of Using the Three Wave & Guardrail Making Machine

Implementing the Three Wave & Guardrail Making Machine brings numerous advantages to manufacturers and end users alike

- Increased Production Speed The automation and efficiency of the machine significantly reduce production time, allowing manufacturers to meet tight deadlines and increasing turnover rates.

- Enhanced Product Quality With precise control over manufacturing parameters, the machine ensures that every guardrail produced meets high-quality standards, contributing to overall road safety.

- Lower Labor Costs Automation reduces the need for extensive manual labor, which can lead to substantial savings in labor costs and allow teams to focus on more strategic tasks.

- Scalability The machine can be scaled up or down based on production requirements, providing manufacturers with flexibility in meeting varying demand levels.

Conclusion

The Three Wave & Guardrail Making Machine represents a significant leap forward in the production of essential infrastructure components. With its ability to produce high-quality, durable guardrails quickly and efficiently, it addresses the growing demand for road safety solutions in an increasingly congested world. As technology continues to advance, such machines will play an integral role in shaping the future of infrastructure, ultimately contributing to safer roads and better urban planning. The evolution of guardrail manufacturing reflects the broader trends in industrial innovation, highlighting the importance of adopting advanced technologies to meet modern challenges.